Appointment of means of individual and collective protection. Collective and individual means of protection of the population - report

Full text search:

Home> Report> Life Safety

Ministry of Education and Science of the Russian Federation

Federal Agency for Education

GOU VPO Cherepovets State University

Institute of Pedagogy and Psychology

Discipline report:

Life safety

Collective and individual means of protection of the population

Performed:

Lukina Lena

Checked:

Savicheva T.E.

Cherepovets 2011

Introduction

A. Classification of protective structures

B. Refuge

E. Simplest hideouts

3.Personal protective equipment and their classification

A. Civilian gas masks

B. Extra cartridges

B. Respirators

E. Skin protection

E. Simplest means of skin protection

4. Conclusion

5.List of literature

Introduction

The importance of personal and collective protective equipment is currently very high. They help a person in various situations and industries of a person. Personal protective equipment is used to prevent or reduce human exposure to hazardous and harmful production and natural factors.

The intensive use of natural resources and environmental pollution, the widespread introduction of technology, mechanization and automation systems in all spheres of social and production activities, the formation of market relations are accompanied by the emergence and widespread occurrence of various natural, biological, man-made, environmental and other hazards.

The solution to the problem of life safety consists in ensuring normal (comfortable) conditions for human activity, in protecting a person and his environment (industrial, natural, domestic) from the effects of harmful factors that exceed the normative permissible levels. Maintaining optimal conditions for human activity and rest creates the preconditions for high efficiency and productivity.

In the modern world, numerous dangerous and harmful factors of anthropogenic origin (noise, vibration, electromagnetic fields, ionizing radiation, etc.), associated with industrial, economic and other human activities. In addition, cases of terrorist acts have become more frequent. As a result of all these emergencies, mass destruction of people is possible. To protect people, individual and collective protective equipment is used.

Collective protective equipment and their classification

A. Classification of protective structures

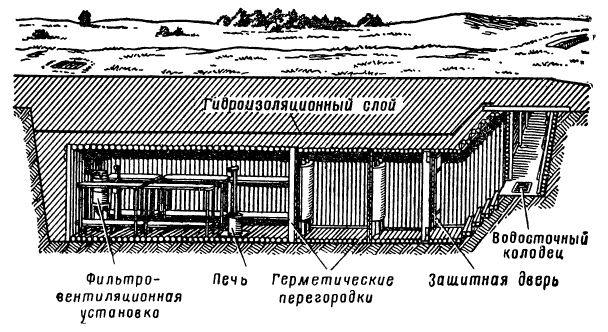

One of the most reliable ways to protect the population from the effects of hazardous chemicals in accidents at chemically hazardous facilities and from radioactive substances in case of malfunctions at nuclear power plants, during natural disasters: storms, hurricanes, tornadoes, snow drifts and, of course, in the case of the use of conventional and modern weapons means of mass destruction is a shelter in defensive structures. Such structures include shelters and anti-radiation shelters (RDA). In addition, the simplest shelters can be used to protect people.

Protective structures at the location can be built-in, located in the basements and basements of buildings and structures, and free-standing, erected outside buildings and structures. They are placed as close as possible to the places of work or residence of people.

In terms of construction time, protective structures are subdivided into those built in advance, that is, in peacetime, and pre-fabricated ones, which are constructed in anticipation of any emergencies (events) or in the event of a military threat.

B. Refuge

They are characterized by the presence of strong walls, ceilings and doors, the presence of hermetic structures and filter ventilation devices. All this creates favorable conditions for people to stay in them for several days. Entrances and exits are made no less reliable, and in case of blockage - emergency exits (manholes).

The capacity of the shelter is determined by the sum of sitting and lying places (second and third tiers): small - up to 600, medium - from 600 to 2000, and large - over 2000 people.

Long-term stay of people is possible thanks to reliable power supply (diesel power plant), sanitary devices (water supply, sewerage, heating), radio and telephone communications, as well as supplies of water, food and medicine. The air supply system, in turn, will provide people not only with the required amount of air, but will give it the required temperature, humidity and gas composition.

C. Pre-fabricated shelters (BVU)

Adaptation of basement, basement and ground floors of buildings, as well as cellars, basements, undergrounds, vegetable stores for BWUs, and they are built in cities and at facilities when there is not a sufficient number of shelters built in advance. Such structures are erected in a short time (within a few days) from reinforced concrete prefabricated structures, sometimes from timber. Their capacity, as a rule, is small - from 3 to 200 people.

STBs, as well as shelters built in advance, should consist of rooms for shelters, places for the location of filtering and ventilation equipment, a sanitary unit, and have an emergency supply of water. In shelters of small capacity, the sanitary unit and waste containers are located in the vestibule, and the tanks with water are located in the room for the sheltered. Internal equipment of BWU includes air supply means, sand and slag filters, cloth filters; air intake and exhaust openings (boxes), lighting devices, bunks and benches.

BVU ventilation performs work in two modes. For this, various designs of mechanical and manual fans are used.

D. Anti-radiation shelters (PRU)

They are used mainly to protect the population of rural areas and small towns from radioactive contamination. Some of them are being built in advance in peacetime, others are being erected (adapted) only in anticipation of emergencies or the emergence of a threat of an armed conflict.

It is especially convenient to arrange them in basements, basements and first floors of buildings, in household structures - cellars, underground vegetable stores. A number of requirements are imposed on the PRU.

They must ensure the need to attenuate radioactive radiation, protect in case of accidents at chemically hazardous facilities, save lives of people during some natural disasters, storms, hurricanes, tornadoes, typhoons, snow drifts. Therefore, they should be located near the places of residence (work) of the majority of the sheltered. The height of the premises should, as a rule, be at least 1.9 m from the floor to the bottom of the protruding floor structures.

When adapting underground, cellars and other similar buried premises for shelters, their height can be lower - up to 1.7 m. In large PRUs, two entrances (exits) are arranged, in small ones - up to 50 people - one is allowed. At the entrances, ordinary doors are installed, but they are necessarily sealed in the places where the canvas adjoins the door frames.

The norm of the floor area of the main premises of the PRU for one sheltered person is taken, as in the shelter, equal to 0.5 m2 with a two-tier arrangement of bunks. A room for storing contaminated street clothes will be equipped at one of the entrances.

The PRU provides for natural ventilation or ventilation with mechanical induction. Natural is carried out through the air intake exhaust shafts. The openings for the supply air supply are located in the lower area of the premises, the exhaust openings - in the upper area. Heating of the shelters is arranged in common with the heating system of the buildings in which they are equipped.

E. Simplest hideouts

The simplest shelters of a slit of a crack, trench, trench, dugout, dugouts have passed a long historical path, but have changed little in essence. They were quite reliable protection for soldiers in the First World War and played an even more exceptionally important role in the Great Patriotic War. And now, in any emergency situations of a military (conflict) nature, they remain simple and well-proven protection. This is confirmed by the events in Chechnya.

All these structures are as simple as possible; they are erected with the minimum expenditure of time and materials. The slot can be open and closed. It is a ditch 1.8-2 m deep, 1-1.2 m wide at the top, and 0.8 m at the bottom. Usually, a crack is built for 10-40 people.

Personal protective equipment and their classification

The personal protective equipment of the respiratory system includes filtering gas masks (general, civil, children's, industrial), insulating gas masks, respirators and the simplest means. To the means of skin protection - insulating suits (overalls, sets), protective and filtering clothing, the simplest means (work and household clothing), adapted in a certain way.

A. Civilian gas masks

To protect the population, the most widely used filtering masks GP-5 (GP-5M) and GP-7 (GP-7V). Civilian gas mask GP-5 is designed to protect a person from getting into the respiratory system, eyes and face of radioactive, poisonous, emergency chemically hazardous substances and bacterial agents. The principle of protective action is based on preliminary cleaning (filtration) of the inhaled air from harmful impurities.

The GP-5 gas mask consists of a filtering-absorbing box and a front part (helmet-mask). It does not have a connecting tube. In addition, the set includes a bag for a gas mask and anti-fog films or a special "pencil". The set of the GP-5M gas mask includes a helmet-mask with a membrane box for an intercom

The civilian gas mask GP-7 is one of the latest and most advanced models. It reliably protects against poisonous and many chemically hazardous substances, radioactive dust and bacterial agents. Consists of a filtering-absorbing box GP-7k, front part of MGP, anti-fog films (6 pcs.), Insulation cuffs (2 pcs.), A protective knitted cover and a bag. Its weight in a set without a bag is about 900 g, a filtering-absorbing box - 250 g, front part - 600 g. The front part of IHL is made in three heights. It consists of a volumetric mask with an "independent" obturator in one piece with it, a spectacle assembly, an intercom (membrane), inhalation and exhalation valve assemblies, a fairing, a headgear and pressure rings for fixing anti-fog films. The "independent" seal is a strip of thin rubber and serves to create a reliable seal on the front of the head. In turn, the sealing of the second, due to the ability of the obturator to stretch independently of the mask body. In this case, the mechanical effect of the face on the head is very insignificant.

B. Additional cartridges

In order to expand the capabilities of gas masks to protect against hazardous chemicals, additional cartridges were introduced for them (DPG-1 and DPG-3). Gas masks GP-7, PDF-2D and PDF-2Sh, equipped with a filtering-absorbing box GP-7K, can be used to protect against iodine radionuclides and its organic compounds. DPG-3 complete with a gas mask protects against ammonia, chlorine, dimethylamine, nitrobenzene, hydrogen sulfide, carbon disulfide, hydrocyanic acid, tetraethyl lead, phenol, phosgene, furfural, hydrogen chloride, cyanogen chloride and ethyl mercaptan. DPG-1, in addition, also protects against nitrogen dioxide, methyl chloride, carbon monoxide and ethylene oxide. Outside air, getting into the filtering-absorbing box of the gas mask, is preliminarily cleaned of aerosols and vapors of hazardous chemicals, then entering an additional cartridge, it is finally cleared of harmful impurities. Inside the DPG-1 cartridge there are two layers of charge - a special absorber and hopcalite. DPG-3 has only one absorber layer. To protect the charge from moisture during storage, the necks must be permanently closed: the outer one with a screwed cap with a gasket, the inner one with a screwed cap. Gas mask GP-7 complete with additional cartridge DPG-3, front part of MGP. The cartridges in the manufacturer's packaging have a guaranteed shelf life of 10 years.

The hopcalite cartridge is also an additional cartridge for gas masks for protection against carbon monoxide. By design, it resembles DPG-1 or DPG-3, it is equipped with a desiccant and actually hopcalite. The desiccant is a silica gel impregnated with calcium chloride. Designed to absorb water vapor in the air in order to protect hopcalite from moisture, which, when humidified, loses its properties.

B. Respirators

Respirators are lightweight respiratory protection against harmful gases, vapors, aerosols and dust. They are widely used in mines, in mines, at chemically hazardous and dusty enterprises, when working with fertilizers and pesticides in agriculture. They are used at nuclear power plants, when cleaning scale at metallurgical enterprises, during painting, loading and unloading and other works.

Respirators are divided into two types. The first one is respirators, in which a half mask and a filter element simultaneously serve as a front part. The second one cleans the inhaled air in filter cartridges attached to the half mask. By appointment, they are subdivided into anti-dust, anti-gas and gas-dust protection. Anti-dust protectors protect the respiratory system from aerosols of various types, anti-gas ones - from harmful vapors and gases, and gas-dust ones - from gases, vapors and aerosols when they are simultaneously present in the air.

Fine-fiber filter materials are used as filters in anti-dust respirators. The most widespread are polymeric filter materials of the FP type (Petryanov filter) due to their high elasticity, mechanical strength, high dust holding capacity, and most importantly, because of their high filtering properties.

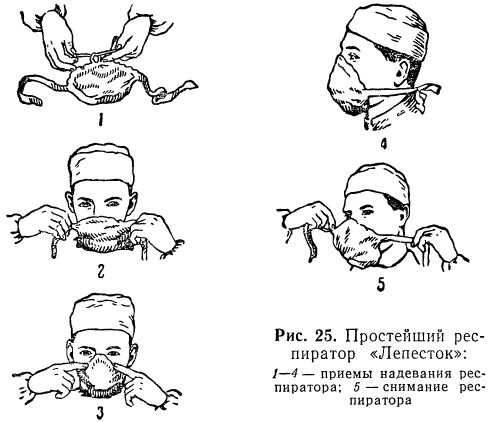

D. Simplest respiratory protection

When there is no gas mask or respirator, that is, protective equipment made by the industry, you can use the simplest - a cotton-gauze bandage and an anti-dust fabric mask (PTM). They reliably protect the human respiratory organs (and PTM, the skin of the face and eyes) from radioactive dust, harmful aerosols, bacterial agents, which will prevent infectious diseases. It should be remembered that they do not protect against OV and many AHOV.

A cotton-gauze bandage is made as follows. Take a piece of gauze 100 cm long and 50 cm wide; in the middle part of the piece, on an area of 30 x 20 cm, an even layer of cotton wool about 2 cm thick is placed; the ends of the gauze free from cotton wool are wrapped along the entire length of the piece on both sides, closing the cotton wool; the ends of the gauze (about 30 - 35 cm) on both sides in the middle are cut with scissors, forming two pairs of strings; the ties are fastened with stitches of thread (sewn). If you have gauze but no cotton wool, you can make a gauze bandage. To do this, instead of cotton wool, 5-6 layers of gauze are placed in the middle of a piece of gauze.

When used, a cotton-gauze (gauze) bandage is applied to the face so that its lower edge covers the bottom of the chin, and the upper one reaches the eye sockets, while the mouth and nose should be well closed. The cut ends of the bandage are tied: the lower ends are at the crown of the head, the upper ones are at the back of the head. Anti-dust goggles are used to protect the eyes.

Anti-dust fabric mask PTM-1 consists of a body and attachment. The body is made of four to five layers of fabric. For the top layer, coarse calico, staple fabric, calico, knitwear are suitable, for the inner layers - flannel, bumazey, cotton or woolen fabric with a fleece (the material for the bottom layer of the mask adjacent to the face should not fade). The fabric may not be new, but it is always clean and not very worn. The mask attachment is made from one layer of any fine material.

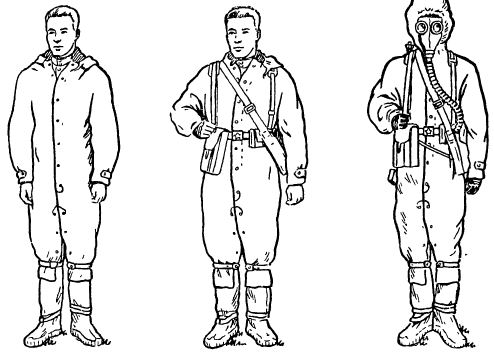

E. Skin protection

Designed to protect people from the effects of chemically hazardous, poisonous, radioactive substances and bacterial agents. All of them are divided into special and improvised. In turn, special ones are subdivided into insulating (airtight) and filtering (breathable). Insulating type overalls are made of materials that do not allow a drop or vapor of toxic substances to pass through, provide the necessary tightness and, thanks to this, protect a person.

Structurally, these protective equipment, as a rule, are made in the form of jackets with hoods, semi-overalls and overalls. When put on, they provide significant overlapping areas of the articulation points of various elements.

In civil defense organizations at the facilities of the national economy, in civil defense units and formations, in the chemical troops and other special forces of the Armed Forces, for a long time, such insulating skin protection equipment as a combined-arms protective kit, a light protective suit L-1, protective overalls have been equipped.

Protective filtering clothing (PFD) should not be discounted as well. It has many advantages over insulating agents. It is easier to work in it, a person gets less tired, his actions are less constrained.

It must be remembered that all these funds are used in combination with filtering gas masks.

Skin protection products are worn on uncontaminated areas. In isolating agents, a person overheats and gets tired quickly. To increase the duration of work at temperatures above + 15 ° C, wet screening (cooling) overalls made of cotton fabric are used, worn over the skin protection. Shielding overalls are periodically moistened with water.

For work in insulating skin protection, the permissible periods have been established, depending on the air temperature.

If the work is carried out in the shade, as well as in cloudy or windy weather, these periods can be increased by about 1.5 times.

The removal of protective equipment is carried out on an uncontaminated area or outside the emergency work zone in such a way as to exclude contact of unprotected parts of the body and clothing with the outside of the protective equipment.

E. The simplest means of skin protection

As the simplest means of protecting human skin can be used primarily industrial clothing: jackets, trousers, overalls, robes with hoods, sewn in most cases from tarpaulin, fire-retardant or rubberized fabric, rough cloth. They are able not only to protect against contact with the skin of radioactive substances in accidents at nuclear power plants and other radiation hazardous facilities, but also from drops, vapors and aerosols of many hazardous chemicals. Tarpaulin products, for example, protect against droplet liquid chemicals and hazardous chemicals in winter up to 1 hour in summer - up to 30 minutes. Of the items of household clothing, raincoats and capes made of rubberized fabric or fabric covered with PVC film are most suitable for this purpose. Winter things can also provide protection for up to 2 hours: coats made of coarse cloth or drape, quilted jackets, sheepskin coats, leather coats. It all depends on the specific weather and other conditions, the concentration and state of aggregation of chemically hazardous or toxic substances in emergency situations. After appropriate preparation, other types of outerwear can also provide protection: tracksuits, jackets, especially leather, denim clothing, raincoats made of waterproof fabric. To protect your feet, it is best to use rubber boots for industrial or household use, rubber boots, galoshes. You can also use shoes made of leather and imitation leather, but preferably with rubber galoshes. Rubber products are able to prevent droplets of liquid chemicals and hazardous substances through up to 3 - 6 hours. You should wear rubber or leather gloves on your hands, you can use tarpaulin mittens. Women are advised to give up skirts and wear pants. In order for ordinary clothing to better protect against vapors and aerosols of hazardous chemicals and chemicals, it must be soaked in a special solution. How is it done when preparing protective filter clothing (FFA). Only fabrics are to be impregnated. To impregnate one set of clothing and accessories to it (chest flap, hood, gloves, sock), 2.5 liters are enough. solution. The impregnating solution can be prepared on the basis of aqueous synthetic detergents (OP-7, OP-10, "Novost", "Don", "Astra", etc.) used for washing clothes. Alternatively, you can use mineral and vegetable oils for this. In the simplest means of skin protection, you can overcome contaminated areas of the terrain, leave the areas where there was a spill or release of hazardous chemicals. For a certain period of time, these funds protect the human body from direct contact with drops, smears, aerosols and vapors of harmful and toxic substances, which will significantly reduce the likelihood of injury.

Conclusion

Thus, having considered the theoretical aspects of this problem, it can be argued that ensuring human security is the most important thing in the world community. The purpose of our work was to study the protective properties, personal and collective protective equipment and the rules for their use. We theoretically examined the properties of protective equipment for the skin, hands, feet and respiratory organs. Revealed their main characteristics.

Bibliography

"Military encyclopedic dictionary". - M .; Military Publishing House, 2003.

"Civil defense": a tutorial. - M .: Education, 2005.

"OBZH textbook for 10th grade students of educational institutions." Moscow "Education", 2003

"LIFE SAFETY FUNDAMENTALS. Fundamentals of Life Safety ": educational-methodical journal. -M .: "Russian Journal" publishing house. - 1998 - 2000. - No. 1-12.

"Fundamentals of Life Safety". 10th grade: textbook for general education. Institutions / V.N. Latchuk, V.V., Mironov, S.N. Vangorodsky. - 4th ed., Rev. - M .: Bustard, 2003 .-- 320 p .: ill.

Collective and fit individual funds protection, compliance with the radiation protection, preparation and implementation ... 2001 6 Organization and conduct of civil defense and protection population and territories from natural and man-made emergencies ...

Protection population in emergencies (6)

Abstract >>And cultural property in safe areas; granting the population funds collective, and individual protection(shelters, gas masks, etc.); carrying out emergency ...

Social emergencies and protection from them

Book >> Life SafetyAccumulated funds individual and collective funds protection and property, as well as for training and education population and ... dressing bag individual(PP). Collective facilities protection(protective structures) are intended for protection population from all of us...

The system of social protection workers from occupational risks

Abstract >> State and lawG.V. Khlopin. In recent years, social protection population, in particular workers, becomes an object ... etc.); c) admissible in the presence of effective collective and individual funds protection, regular biological monitoring of health status ...

To prevent or reduce the impact of harmful and hazardous production factors, as well as to protect against pollution, protective equipment is used, which are divided into two categories: collective protective equipment (RPC) and personal protective equipment (PPE).

VMS and PPE are divided into classes for their intended purpose, including various types, which, in turn, depending on a specific hazardous and (or) harmful production factor or on design features, are divided into types. The choice of the type of protective equipment is carried out taking into account the safety requirements for a specific process or type of work.

Personal protective equipment is used in cases where the safety of work cannot be ensured by the design of equipment, organization of production processes, architectural and planning solutions and collective protective equipment. Marking must comply with GOST 12.4.115 and standards for marking specific PPE.

Personal protective equipment, depending on the purpose, is divided into classes: protective equipment for the respiratory system, legs, hands, head, face, eyes, hearing, as well as protective equipment against falls from a height, special protective clothing and insulating suits, dermatological protective equipment and etc.

Collective protective equipment, depending on the purpose, is divided into classes: means of normalizing the air environment of industrial premises and workplaces (pressure, air humidity, etc.), lighting; protective equipment against an increased level of laser radiation, noise, vibration, ultrasound, etc .; protective equipment against falling from a height and against the influence of mechanical factors (moving machines and mechanisms, etc.); protective equipment against high or low air temperatures and temperature extremes, against the effects of chemical and biological factors, etc.

When choosing protective equipment, preference should be given to collective protective equipment.

17. Requirements for the organization of training in safe working methods, qualification requirements for workers. Job and production instructions

The employee is obliged to undergo training in safe methods and techniques for performing labor protection work, providing first aid in case of industrial accidents, training at the workplace and testing knowledge of labor protection requirements (Article 214 of the Labor Code of the Russian Federation).

In accordance with article 76 of the Labor Code of the Russian Federation, the employer is obliged to suspend from work (not allow to work) an employee who has not undergone training and testing of knowledge and skills in the field of labor protection in the prescribed manner.

All employees of the organization, including its head, are subject to training in labor protection and verification of knowledge of labor protection requirements.

The employer is responsible for the organization and timeliness of labor protection training and testing the knowledge of the labor protection requirements of the company's employees in the manner prescribed by the legislation of the Russian Federation.

Labor safety briefings

primary in the workplace;

repeated in the workplace;

unscheduled in the workplace;

target in the workplace.

Qualifying requirements - the requirements for training, professional knowledge, skill and experience, as well as an appropriate state of health, which enable the expert to perform his functions properly.

Job description- This is an internal organizational and administrative document governing the powers, responsibilities and duties of an employee in a position held in a particular organization.

Job descriptions developed by the head or his deputies for their subordinates and agreed with lawyers (legal department). The job description is drawn up in three copies for each employee: one copy is kept in the personnel department, the second is at the head of the department (unit), the third is at the employee.

Correctly drawn up job descriptions allow: - to rationally distribute functional responsibilities and determine connections between employees, thereby increasing the timeliness and reliability of the implementation of strategic, tactical and operational tasks; - to specify the rights and responsibilities; - to increase personal and collective responsibility; - aggregate information to conduct a reasonable selection of employees when hiring, assess the level of compliance of candidates for vacant positions; - to give each employee the knowledge of what actions are expected of him, by what criteria the results of his work will be assessed, what it is necessary to focus on in order to improve the level of qualifications, etc .; - to assess the activities of the employee and make a decision on his future fate (dismissal, promotion, retraining, etc.); - serve as an evidence base in labor disputes in the relevant commissions, supervisory authorities and the court.

The initial data for the development of job descriptions are: - the scope of the enterprise, its organizational and functional structure, business processes, etc .; - provisions on structural divisions: departments, services, bureaus, etc .; - labor legislation of the Russian Federation: Labor Code of the Russian Federation, etc .; - a unified classification reference book (CEN) of positions of managers, specialists and other employees; - a unified tariff and qualification reference book (ETKS) of jobs and professions of workers; - and etc.

Manufacturing instruction- this is an operational document of the organization, intended for the maintenance personnel of the hazardous industrial facility, prescribing the procedure for performing official duties in the conduct of the technological process. The content of the production instruction is established by the Federal norms and rules in the field of industrial safety, the governing documents of the organization, taking into account the specifics of production and operating technical devices.

1. General Provisions; 2. Information about briefings and knowledge testing; 3. Subordination and relationship with related jobs; 4. Rights, obligations, responsibility; 5. Reception and delivery of the shift; 6. Description of the workplace, materials, equipment, technological scheme, norms of the technological regime; 7. Start and stop of equipment; 8. Deviations from the normal technological regime and methods of their elimination; 9. Emergency stop; 10. Basic rules for safe work.

The instruction is approved by the head or technical manager of the organization operating the hazardous industrial facility.

Changes are made to the production instruction or the document is completely revised in the event of changes in regulatory documents, governing documents of the organization, which are the basis for the development of production instructions.

Ministry of Education and Science of the Russian Federation

Federal Agency for Education GOU VPO

All-Russian Correspondence Financial and Economic Institute

Department of Labor Economics and Sociology

TEST

on life safety on the topic:

Collective and personal protective equipment for workers

Penza - 2009

Introduction

Working conditions in different areas of production: industrial hazards and hazards

Collective remedies

Personal protective equipment (including workwear and safety footwear)

Conclusion

Literature

Introduction

This topic is quite relevant in our time. Protecting health and the environment are the most pressing issues in our daily life. Due to excessive gas pollution, the ozone layer is destroyed and a greenhouse effect occurs. And this brings with it very large-scale problems in the form of global warming, and the consequences are simply irreparable and very terrible. And probably almost everyone has health problems, and few people think about the true cause of their diseases. But you need to eliminate the cause of their appearance, not the consequences. In addition to all this, there are quite a few traumatic and hazardous to health professions, being on which you need to know the precautions and safety precautions in order to protect yourself from injury. Therefore, it is absolutely necessary to study this topic in detail.

The purpose of the work is to develop recommendations for the use of collective and individual protective equipment for workers. Based on this goal, the task is to reveal the working conditions at various production sites, including occupational hazards and hazards, to study all collective and individual protective equipment (including overalls and safety footwear).

In this work, the literature of the most popular and well-known authors was used, who devoted their work to the study of hazard factors and the fight against them. These are the tutorials by P.E. Schlender, L.A. Muravya, S.V. Belova. They describe in detail all harmful substances and hazardous factors at work, classify collective and individual protective equipment against them, giving a description of each.

Working conditions in different areas of production: industrial hazards and hazards

One of the most important conditions for normal human life in the performance of professional functions is the maintenance of the thermal balance of the body. Significant fluctuations in the parameters of the industrial microclimate have a significant impact on the state of heat exchange between humans and the environment.

Industrial microclimate depends on the climatic zone and season of the year, the nature of the technological process, the type of equipment used, the size of the premises and the number of employees, heating and ventilation conditions. The normative indicators of the industrial microclimate are established by GOST 12.1.005-88 and SanPiN 2.2.4.584-96.

These norms regulate the microclimate indicators in the working area of the industrial premises: temperature, relative humidity, air velocity, depending on the ability of the human body to acclimatize at different times of the year, the nature of clothing, the intensity of the work performed and the nature of heat generation in the working room.

Industrial ventilation . Distinguish between natural and mechanical ventilation systems. With natural ventilation, the movement of air masses is carried out due to the resulting pressure difference outside and inside the building. With mechanical air is supplied to production premises or removed from them through ventilation duct systems using special mechanical stimuli.

Lighting is one of the most important factors affecting human performance and productivity. Deviations in lighting harm the health of workers, can cause diseases (myopia, spasm, accommodation), are fraught with a decrease in mental and physical performance, and an increase in the number of errors in production processes. There are three types of lighting - natural, artificial and mixed. The first is created by direct sunlight and diffused light of the firmament and changes depending on the geographical latitude, time of year and day, the degree of cloudiness and transparency of the atmosphere. The second is by electric light sources (gas-discharge lamps and incandescent lamps). Combined lighting is called lighting, in which insufficient natural light is supplemented by artificial light.

Chemical substances, synthetic materials that are irrationally used in industrial conditions are of great danger. Vapors, gases, liquids, aerosols, compounds, mixtures in contact with the human body can cause diseases or deviations in the state of health. Human exposure to hazardous substances can be accompanied by poisoning and injury.

In production, toxic substances enter the human body through the respiratory tract, gastrointestinal tract and skin.

In accordance with the general toxicological classification, the following types of effects on living organisms are distinguished:

Nerve-paralytic (convulsions, paralysis);

Skin-resorptive (local inflammation in combination with general toxic phenomena);

General toxic (coma, cerebral edema, convulsions);

Teary and irritating (irritation of the mucous membranes of the eyes, nose, throat);

Psychotropic (violation of mental activity, consciousness).

In addition, poisons are selectively toxic. On this basis, they are divided into: cardiac, nervous, hepatic, renal, blood, pulmonary.

The classification of hazardous substances according to the degree of hazard includes four classes. Extremely hazardous substances, MPC< 0,1 мг/м3 (например, свинец, ртуть имеют ПДК = 0,01 мг/м3). Высокоопасные вещества, ПДК = 0,1-1,0 мг/м3 . Умеренно опасные, ПДК = 1,0-10 мг/м3. Малоопасные, ПДК >10 mg / m3.

By the nature of development and duration of the course, two main forms of occupational poisoning are distinguished - acute and chronic.

By the nature of the effect, chemicals are divided into general toxic, irritating, synsibilizing, mutagenic, carcinogenic, affecting reproductive function.

This classification does not take into account a large group of aerosols (dust), which do not have pronounced toxicity, but have a fibrogenic effect on the human body. Aerosols of coal, coke, soot, animal and vegetable dust, silicate and silicon-containing dust, getting into the respiratory system, cause damage to the mucous membrane of the upper respiratory tract.

Mechanical vibrations. These include: vibration, noise, infrasound, ultrasound. All these physical processes are associated with the transfer of energy, which, at a certain value and frequency, can have an adverse effect on a person: cause various diseases, create additional hazards.

Vibration – these are small mechanical vibrations arising in elastic bodies. Human exposure is classified according to the mode of transmission of vibrations; direction of vibration; time characteristic. Depending on the method of transmitting vibrations to a person, vibration is divided into general and local (local). General vibration is transmitted through the support surfaces to the body of a sitting or standing person. Local vibration is transmitted through the hands or parts of the human body in contact with vibrating surfaces. According to the direction of action, vibration is divided into: vertical and horizontal (from back to chest, from right shoulder to left shoulder). According to the time characteristic, a constant is distinguished, for which the monitored parameter changes by no more than 2 times (6 dB), and a non-constant, changing by more than 2 times. Vibration is one of the factors with high biological activity. Its effect depends on the frequency and amplitude of fluctuations of the duration of exposure, the place of application and other conditions. The resonance of the human body occurs under the influence of external forces when the natural frequencies of vibrations of internal organs coincide with the frequencies of external forces.

When the general vibration affects the body, the musculoskeletal system, the nervous system and such analyzers as the vestibular, visual, and tactile ones suffer. Local vibration causes spasms of the vessels of the hand, forearms, associated with a violation of the supply of blood to the extremities. At the same time, vibrations act on nerve endings, muscle and bone tissue.

Noise, infrasound and ultrasound refer to acoustic vibrations that can be both audible and inaudible. Acoustic vibrations in the range of 16 Hz - 20 kHz, perceived by a person with normal hearing, are called sound; vibrations with a frequency of less than 16 Hz - infrasonic , and with a frequency above 20 Hz - ultrasonic . Spreading in space, sound vibrations create an acoustic field.

Any unwanted sound is commonly referred to as noise. According to the classification composition, depending on the predominance of sound energy in the corresponding frequency range, low-, medium- and high-frequency noises are distinguished; by temporal characteristics - permanent and non-permanent; by the duration of action - long-term and short-term; on the spectrum - broadband and tonal.

Intense industrial noise leads to a decrease in attention and an increase in the number of errors during work. The entire human body is exposed to noise: it depresses the central nervous system, causes a change in the rate of respiration and pulse, contributes to metabolic disorders, the occurrence of cardiovascular diseases, stomach ulcers, etc.

When the body is exposed to infrasound with a level of up to 150 dB, unpleasant subjective sensations and functional changes can occur: disturbances in the cardiovascular and respiratory systems, the central nervous system, and the vestibular analyzer.

In terms of its physical nature, ultrasound does not differ from audible sound. The difference from noise is characterized by high intensity values. Ultrasound can be low frequency and high frequency. Long-term action of ultrasound causes functional disorders of the nervous, cardiovascular and endocrine systems, hearing loss, changes in blood composition, increased blood pressure.

Electromagnetic fields and radiation are referred to as non-ionizing radiation. Natural sources of electromagnetic fields and radiation are atmospheric electricity, radio emissions from the Sun and galaxies, and the electric and magnetic fields of the Earth. All industrial and household electrical and radio installations are sources of artificial fields and radiation, but of varying intensity.

Electrostatic fields arise when working with easily electrifying materials and products, when operating high-voltage direct current installations. Sources of constant electrostatic and magnetic fields are: direct current electromagnets and solenoids, magnetic circuits in electrical machines and apparatus, sintered magnets used in radio engineering. Sources of electric fields of industrial frequency (50 Hz) are: power lines and open switchgears, including switching devices, protection and automation devices, measuring instruments, connecting buses, as well as all high-voltage installations of industrial frequency.

Power frequency magnetic fields arise around any electrical installations and power frequency conductors. Sources of electromagnetic radiation of radio frequencies are powerful radio stations, antennas, microwave generators, induction and dielectric heating installations, radars, measuring and control devices, high-frequency devices and devices in medicine, research installations.

Long-term exposure of a person to electromagnetic fields of industrial frequency leads to various disorders: headache, lethargy, sleep disturbance, memory loss, increased irritability, pain in the heart, irregular heartbeat. There are functional disorders in the cardiovascular system, nervous system, changes in the composition of the blood. The maximum permissible values of the strength of the electric and magnetic fields with a frequency of 50 Hz, depending on the time spent in it, are established by GOST 12.1.002-84 and SanPiN 5802-91.

A significant part of non-ionizing electromagnetic radiation is made up of radio waves and vibrations in the optical range (infrared, visible, ultraviolet radiation). Depending on the place and conditions of exposure to electromagnetic radiation of radio frequencies, four types of radiation are distinguished: professional, non-professional, household and for medical purposes, and by the nature of the radiation - general and local.

The thermal effect is a consequence of the absorption of energy by the human body. Starting from a certain limit, the human body cannot cope with the removal of heat from individual organs, and their temperature may rise. Exposure to this radiation is especially harmful to tissues with an underdeveloped vascular system or insufficient blood circulation (eyes, brain, kidneys, stomach, etc.). With prolonged exposure to radiation, metabolic disorders, disorders of the nervous system, etc. can occur.

Infrared radiation is a part of electromagnetic radiation with a wavelength of 780 to 1000 microns, the energy of which, when absorbed by a substance, causes a thermal effect. The most active is short-wave radiation, since it has the highest photon energy, is able to penetrate deeply into the tissues of the body and is intensively absorbed by the water contained in the tissues. In humans, the organs most affected by infrared radiation are the skin and organs of vision.

Visible radiation at high energy levels can also be harmful to the skin and eyes.

Ultraviolet radiation, like infrared, is part of the electromagnetic radiation with a wavelength of 200 to 400 nm. Natural solar ultraviolet radiation is vital and has a beneficial stimulating effect on the body.

Radiation from artificial sources can cause acute and chronic occupational injuries. The most vulnerable organ is the eyes. Acute eye lesions are called electrophthalmia. Getting on the skin, ultraviolet radiation can cause acute inflammation, swelling of the skin. The temperature may rise, chills, headache may appear.

Laser radiation is a special type of electromagnetic radiation generated in the wavelength range of 0.1-1000 microns. It differs from other types of radiation in monochromaticity (strictly of the same wavelength), coherence (all radiation sources emit electromagnetic waves in the same phase) and sharp beam directivity. Acts selectively on various bodies. Local damage is associated with eye irradiation, skin damage. The general effect can lead to various functional disorders of the human body (nervous and cardiovascular systems, blood pressure, etc.).

Collective remedies

Collective protective equipment is divided into: protective, safety, braking devices, protective devices, automatic control and signaling devices, remote control, safety signs.

Locking devices, according to the principle of operation, are divided into mechanical, electronic, electrical, electromagnetic, pneumatic, hydraulic, optical, magnetic and combined. Interlocking devices prevent a person from entering the hazardous area or during his stay in this area eliminate the hazardous factor.

Electrical interlocking is used on electrical installations with voltages from 500 V and above, as well as on various types of technological equipment with an electric drive. It ensures that the equipment is turned on only when there is a fence. Electromagnetic (radio frequency) blocking is used to prevent a person from entering a hazardous area. Optical blocking is used in press-forging and mechanical shops of machine-building plants. Electronic (radiation) blocking is used to protect hazardous areas on presses, guillotine shears and other types of technological equipment used in mechanical engineering.

Braking devices are subdivided: by design - into shoe, disc, conical and wedge; by the method of actuation - into manual, automatic and semi-automatic; according to the principle of action - on mechanical, electromagnetic, pneumatic, hydraulic and combined; by appointment - for working, backup, parking and emergency braking.

It is possible to use a movable (removable) fence. It is a device interlocked with the working bodies of the mechanism or machine, as a result of which it closes access to the working area when a dangerous moment occurs. Such limiting devices are especially widespread in machine tool building (for example, in machines with CNC OFZ-36).

Portable fences are temporary. They are used for repair and commissioning work to protect against accidental contact with live parts, as well as from mechanical injury and burns. In addition, they are used at permanent workplaces of welders to protect others from the effects of an electric arc and ultraviolet radiation (welding stations). They are most often performed in the form of shields 1.7 m high. To withstand the loads from particles flying off during processing and accidental influences of the operating personnel, the fences must be strong enough and well attached to the foundation or parts of the machine.

Safety devices are used to automatically turn off machines and equipment in case of deviation from normal operation or when a person enters the danger zone. These devices can be blocking and restrictive. Blocking devices according to the principle of operation are: electromechanical, photoelectric, electromagnetic, radiation, mechanical. Restrictive devices are components of machines and mechanisms that are destroyed or fail when overloaded.

To ensure the safe and reliable operation of the equipment, information, warning, emergency automatic control and signaling devices are very important. Control devices are instruments for measuring pressures, temperatures, static and dynamic loads that characterize the operation of machinery and equipment. By combining monitoring devices with alarm systems, their efficiency is significantly increased. Alarm systems are: sound, light, color, sign, combined.

Various technical measures are used to protect against electric shock. These are low voltages; electrical separation of the network; control and prevention of insulation damage; protection against accidental contact with live parts; protective grounding; protective shutdown; personal protective equipment.

Long-term work on a personal computer can adversely affect a person. A personal computer (PC) monitor is a source of electrostatic fields; weak electromagnetic radiation in the low-frequency and high-frequency ranges; X-ray radiation; radiation of the visible range. With prolonged work on the PC, pain appears in the spine, shoulder joints, neck, pain in the elbow joints, wrists, hands and fingers. The human visual apparatus is subjected to the most severe stress.

When using a PC, great importance is attached to the correct organization of work. The room in which the PCs are located should be spacious, well-ventilated, correctly lit. Lighting should be mixed: natural and artificial. Avoid too much contrast between the brightness of the screen and the surrounding area. Do not work on the computer in a dark or semi-dark room.

Personal protective equipment (including workwear and safety footwear)

In a number of enterprises there are such types of work or working conditions in which the worker may be injured or otherwise exposed to hazardous health. Even more dangerous conditions for people can arise during accidents and the elimination of their consequences. In these cases, personal protective equipment (PPE) must be used to protect a person. Their use should ensure maximum safety, and the inconvenience associated with their use should be minimized. This is achieved by following the instructions for their use. The latter regulate when, why and how PPE should be used, what should be the care for them.

The PPE nomenclature includes an extensive list of equipment used in working conditions (PPE for everyday use), as well as equipment used in emergency situations (PPE for short-term use).

In the latter cases, predominantly isolating personal protective equipment (ISIZ) is used.

When performing a number of production operations (in the foundry, in electroplating shops, during loading and unloading, machining, etc.), is it necessary to wear special clothing (suits, overalls, etc.)? sewn from special materials to ensure safety from the effects of various substances and materials with which you have to work, heat and other radiation. The requirements for workwear are to ensure the greatest comfort for a person, as well as the desired safety.

For some types of work, aprons can be used to protect workwear, for example, when working with cooling and lubricants, during heat exposure, etc. In other conditions, it is possible to use special sleeves,

To avoid injury to feet and toes, protective footwear (boots, boots) must be worn. It is used for the following work: with heavy objects; in construction; in conditions where there is a risk of falling objects; foundry, blacksmith, steel production, etc .; in rooms where the floors are flooded with water, oil, etc.

Some types of safety shoes are equipped with a reinforced sole that protects the foot from sharp objects (such as a protruding nail). Shoes with special soles are designed for working conditions in which there is a risk of injury from falling on slippery ice flooded with water and oil. Special vibration-resistant footwear is used.

For hand protection when working in electroplating shops, foundries, when machining metals, wood, during handling, etc. it is necessary to use special gloves or gloves. Protection of hands from vibrations is achieved by using gloves made of elastic damping material.

Head protectors are designed to protect the head from falling and sharp objects and to cushion impacts. The choice of helmets and helmets depends on the type of work being performed. They should be used under the following conditions:

There is a risk of injury from materials, tools or other sharp objects that fall down, tip over, slide, are thrown or thrown down;

There is a risk of collision with sharp bulging or twisting objects, pointed objects, objects of irregular shape, as well as with suspended or swinging weights;

There is a risk of head contact with the electrical cord.

It is very important to choose a helmet according to the nature of the work being performed, as well as in size, so that it stays firmly on the head and provides sufficient distance between the inner shell of the helmet and the head. If the helmet is cracked or has been subjected to strong physical (in the form of impact or pressure) or thermal stress, it should be discarded.

To protect against harmful mechanical, chemical and radiation effects, eye and face protection equipment is required. These funds are used when performing the following work: grinding, sandblasting, spraying, spraying, welding, as well as when using caustic liquids, harmful thermal effects, etc. These funds are performed in the form of glasses or shields. In some situations, eye protection is used in conjunction with respiratory protection, such as special hats.

In working conditions where there is a risk of radiation exposure, for example, when welding, it is important to select protective filters of the required degree of density. When using eye protection, care must be taken to ensure that they are firmly attached to the head and do not reduce the field of view, and that dirt does not impair vision.

Hearing protection is used in noisy industries, when servicing power plants, etc. There are different types of hearing protection: earplugs and ear muffs. Correct and constant use of hearing protection reduces the noise load for earplugs by 10-20 dBA, for headphones by 20-30 dBA.

Respiratory protection devices are designed to protect against inhalation and ingestion of harmful substances (dust, steam, gas) into the human body during various technological processes. When choosing personal protective equipment for respiratory organs (RPE), you need to know the following: what substances you have to work with; what is the concentration of pollutants; how much time you have to work; what state these substances are in: in the form of gas, vapor or aerosol; is there a danger of oxygen starvation; what are the physical activities during work.

There are two types of respiratory protection: filtering and isolation. Filtering filters supply the working area air purified from impurities into the breathing zone, insulating air from special containers or from a clean space located outside the working area.

Insulating protective equipment should be used in the following cases: in conditions of a lack of oxygen in the inhaled air; in conditions of air pollution in high concentrations or in the case when the concentration of pollution is unknown; in conditions where there is no filter that can protect against contamination; in case heavy work is performed, when breathing through filtering RPE is difficult due to filter resistance.

If there is no need for isolating protective equipment, filter media must be used. The advantages of filter media are lightness, freedom of movement for the employee; the simplicity of the solution when changing the workplace.

The disadvantages of filter media are as follows: filters have a limited shelf life; difficulty breathing due to filter resistance; limited work with the use of a filter in time, if we are not talking about a filter mask, which is equipped with a blower. You should not work using filtering RPE for more than 3 hours during the working day.

For work in especially dangerous conditions (in isolated volumes, during the repair of heating furnaces, gas networks, etc.) and emergency situations (in case of fire, emergency release of chemical or radioactive substances, etc.), ISIZ and various individual devices are used. They find application of ISIZ against thermal, chemical, ionizing and bacteriological effects. The range of such ISIS is constantly expanding. As a rule, they provide comprehensive protection of a person from dangerous and harmful factors, while simultaneously creating protection for the organs of sight, hearing, breathing, as well as protection of individual parts of the human body.

The personnel who clean the premises, as well as those who work with radioactive solutions and powders, must be equipped (in addition to the above-mentioned overalls and footwear) with plastic aprons and oversleeves or plastic coats, additional footwear (rubber or plastic) or rubber boots. When working in conditions of possible air pollution of premises with radioactive aerosols, it is necessary to use special filtering or isolating respiratory protection. Isolating PPE (pneumatic suits, pneumatic helmets) are used when filtering means do not provide the necessary protection against the ingress of radioactive and toxic substances into the respiratory system.

When working with radioactive substances, the means of everyday use include gowns, overalls, suits, safety shoes and some types of dust masks. Overalls for everyday use are made of cotton fabric (outerwear and underwear). If exposure to aggressive chemicals is possible, outer overalls are made of synthetic materials - lavsan.

Means of short-term use include insulating hose and self-contained suits, pneumosuits, gloves and film clothing: aprons, oversleeves, semi-overalls. Plastic clothing, insulating suits, safety footwear are made of durable, easily decontaminated polyvinyl chloride plastic with frost resistance up to -25 ° C or plastic reinforced with a nylon mesh of 80 AM recipe.

Safe work is also ensured by the use of individual protective devices. So, when working at height, in wells and other limited volumes, it is necessary to use rescue belts, safety ropes, as well as PPE.

Conclusion

Technogenic hazards arise due to malfunctions and defects in technical systems, their improper use, and the presence of waste during operation. At the same time, the criteria for the safety of the technosphere when it is polluted with wastes are the maximum permissible concentrations of substances (MPC) and the maximum permissible levels of intensity of energy flows (MPL).

The main safety requirements for technical means and technological processes are regulated by the system GOST, OST, SSBT, SanPiN, SN, in which the normative indicators of MPC and MPU are established.

To protect a person from injury, various means are used, which can be collective and individual, as well as numerous types of eco-bio-protective equipment.

This topic has been disclosed, the goal has been achieved, the tasks have been solved.

References:

1. Belova S.V. Life safety: Textbook for universities. - 2nd ed., Rev. and add. - M .: Higher. shk, 1999;

2. Denisov VV Life safety: Textbook. manual - M .: ICC March, Rostov n / a: IC "Mart", 2003;

3. Ant L.A. Life safety: Textbook. manual for universities. - 2nd ed., Rev. and add. - M .: UNITI, 2002;

4. Strelets V.М. Life safety: Textbook. manual for stud. universities. - Rostov n / a: Phoenix, 2004;

5. Schlender P.E. Life safety: Textbook. allowance, VZFEI - M .: University. Textbook, 2003.

STAVROPOL STATE MEDICAL ACADEMY

Department of Military and Extreme Medicine

Head of the Department of Military and

extreme medicine

Colonel of the medical service N.Z. Saenko

ESSAY

on military toxicology and medical protection

Topic: "MEANS OF INDIVIDUAL AND COLLECTIVE PROTECTION"

Head N.V. Churilov

Performed by a student of group 410

medical faculty

I.Yu. Cheskidova

Stavropol, 2005

Plan.

Introduction

1. General characteristics of protective equipment

2. Personal protective equipment. Classification by purpose and principle of operation

3. Combined-arms filtering gas mask, principle of action of contraindications for use

4. Means of skin protection, purpose, classification

5. Collective remedies

Conclusion.

Introduction

The use of chemical weapons in the First World War led to the need to urgently develop anti-chemical protection equipment, since their absence caused massive defeats and large human casualties.

The first remedy was a wet cotton-gauze bandage on the mouth and nose, moistened with a solution of soda and sodium hyposulfite, an engineer Prokofiev's mask with goggles, soaked in a solution of urotropine or sodium hyposulfite. These wet gas masks protected for a short time and not from all agents.

In 1915, Russian scientist Nikolai Dmitrievich Zelinsky proposed a dry gas mask, which consisted of a box filled with activated carbon and a rubber mask with goggles proposed by Kummant. In 1917, the Germans used mustard gas, from which no gas mask could fully protect. Therefore, there were skin protection products, as well as gas shelters.

General characteristics of protective equipment

After the enemy uses weapons of mass destruction, the safety and protection of personnel in the contaminated area is achieved by the timely and skillful use of military protective equipment, the protective properties of equipment and terrain, the use of medical protective equipment, and the choice of the most expedient ways to overcome dangerous zones.

Without the use of military means of protection, it is practically impossible to ensure the combat operations of units and subunits in the contaminated area, to carry out measures to eliminate the consequences of the use of weapons of mass destruction by the enemy.

By the nature of their application, military means of protection are divided into individual and collective. By the principle of operation, they are distinguished by means of protection of the filtering and isolating type. Personal protective equipment is divided into personal protective equipment for the respiratory system and personal protective equipment for the skin.

Personal protective equipment.

1 Respiratory protection:

a) filtering gas masks:

Combined arms: MO-4U (small combined arms), RSh-4 (with expanded charge), PMG-2 (small gas mask), PMK (small box gas mask), etc.;

Special purpose: ShMS, MM-1, ShR-2;

Civil: GP-5 (GP-5M), GP-7;

Children: PDF-7, PDF-D, PDF-Sh (preschool and school children's filtering gas mask).

b) insulating gas masks:

Pneumatophores with compressed oxygen: KIP-5, KIP-8 (oxygen insulating gas mask);

Pneumatogens with the release of oxygen and oxygen-containing substances at the time of breathing: IP-4, IP-4M, IP-4MK, IP-5, IP-46, IP-46M.

c) respirators: R-2 and RM-2.

2. Means of skin protection:

a) insulating type: OZK, L-1, KZP;

b) filtering type: OKZK, KZS, impregnated uniforms.

Combined arms gas mask. Principle of operation, use.

The filtering gas mask is used to protect against contact with the respiratory system, eyes and face of poisonous, radioactive substances, bacterial agents. The principle of the protective action of the gas mask is based on the fact that the air used for breathing is pre-purified, filtered from harmful impurities. The Russian Army has several types of gas mask boxes. The main box is MO-4U ..

The gas mask consists of a gas mask box and a front part. The gas mask kit includes a gas mask bag, anti-fog films or a special pencil. In winter, the gas mask with the front part of the ShM-41 and ShM-42 is supplemented with insulating cuffs, and with the front part of the MM-1 - the second glasses for glasses. Inside the MO-4U box, according to the inhaled air current, there is a smoke filter and activated carbon - a catalyst charge.

The smoke filter consists of strips of fine fiber compressed paper with added asbestos. These strips are arranged concentrically inside the box (RSh-4) or in the form of an accordion (MO-4U), thereby increasing the filter area up to 2000 cm 2. The filter fibers form a dense network and the smallest convoluted tubules. The smoke filter is designed to clean the inhaled air from aerosols, i.e. from small particles suspended in the air by filtration, delay in the convoluted holes of the filter, therefore it is also called an anti-aerosol filter.

At present, the smoke filter is designed to purify the inhaled air from radioactive substances, bacterial aerosols and some organic substances used in aerosol form. But the OM vapors and gases pass through the filter and are retained in the second layer of the gas mask box.

Charge - activated carbon, designed to purify the air from OM vapors. It is a fine-pored mass of coal, on the micropores of which a chemical reagent with catalysts is applied. The absorption of OM vapors is based on the principles:

a) adsorption - the physical process of retention and compaction of OM molecules on the surface of the absorber (coal) due to molecular cohesion forces. The surface of 1 g of activated carbon is 400-800 m 2. It adsorbs best organic substances with a high boiling point and high molecular weight (sarin, soman, mustard gas).

b) catalytic chemisorption - chemical interaction of organic matter with chemical reagents. The reaction is catalyzed by activated carbon and catalytic additives (oxides of cobalt, copper, chromium compounds);

c) catalytic oxidation of the conversion of OM into a non-toxic compound. To nie due to oxidation with atmospheric oxygen.

The protective properties of the smoke filter are determined by the penetration coefficient, i.e. the ratio of the concentration of air particles that have passed the filter to their concentration in the ambient air, expressed as a percentage.

Protective power is the time in hours or minutes during which a gas mask protects a person from a given toxic agent. The time is calculated from the beginning of the intake of the OM through the gas mask until the moment of the breakthrough of the OM.

The protective power of the gas mask charge depends on the concentration of OM in the air, the minute volume of pulmonary ventilation, on the temperature and humidity of the air. Practically at combat concentrations on the battlefield, the gas mask box of modern gas masks reliably protects for several days of continuous operation.

At medium field concentrations, the box of a modern gas mask provides protection against all OM, RV, BS, except for carbon monoxide, for tens of hours. At very high concentrations up to 50 mg / l, the protective effect for phosgene is 15 minutes, for hydrocyanic acid - 8-10 minutes. The time of protective action of the filtering gas mask depends on the type and concentration of OM, the intensity of work, temperature and humidity.

Currently, there are and are being developed new types of boxes for combined arms and industrial gas masks.

The front part of the gas mask consists of a rubber helmet-mask (for the RSh-4 gas mask - ShM-41Mu or ShMS; for the PMG-2, ShM-66Mu gas mask) with goggles and a fairing, a valve box and a connecting corrugated tube. The front part provides the supply of air purified in a gas-mask box to the respiratory organs and protects the eyes and face from the ingress of substances, radioactive substances and bacteriological agents.

The valve box serves to distribute the flows of inhaled and exhaled air in order to reduce the harmful space (it is equal to 350 cm 3). The valve box SHM-41M accommodates one inhalation and two exhalation valves. The exhalation valve is the most critical and vulnerable part of the valve box, since if it malfunctions, contaminated air will penetrate under the helmet-mask. The presence of two exhalation valves eliminates the leakage of contaminated air into the undermask space.

The connecting tube is used to connect the helmet-mask with the gas mask box. With the upper end, using a screw nut, it connects to the valve box, and the lower end, using a nipple and union nut, to the neck of the gas mask box.

To protect the glasses from fogging, anti-fog films or a special pencil are used. At T - 10 0 C and below, they put on insulating cuffs. The film is inserted with the fogging side to the glass under the pressure ring.

The gas mask bag is used to store and carry the gas mask. It has two compartments: the left one is for the box, the right one is for the connecting tube and the front part, between the compartments there is a pocket for a box with an anti-fog film or a pencil, speech membranes. Includes external API pocket. The bag has a shoulder and waist straps. A 3 x 5 cm tag is attached to the left of the bag, which indicates the number of the box, company, platoon, squad, full name.

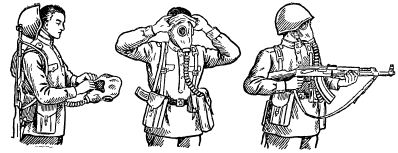

Before putting on the new front part of the gas mask, wipe the outside and inside with a clean cloth slightly moistened with water, and blow out the exhalation valves. When laying the gas mask, the helmet-mask is not bent, but the head and side parts are slightly tucked up so as to protect the glasses of the glasses. The bag with the gas mask should be on the left side, with the valve away from you. The shoulder strap is thrown over the right shoulder.

The gas mask can be in the position: "marching", "ready", "combat". In "marching" - when there is no threat of contamination of OM, RV and BS. The bag is on the left side. When walking, it can be slightly shifted back so that it does not interfere with the movement of the hands. The top of the bag should be at waist level, the flap should be closed. The gas mask is transferred to the "ready" position when there is a threat of infection. In this case, the bag must be secured with a belt tape, slightly pushing it forward, unfasten the valve so that you can quickly use the gas mask. In the "combat" position, the front part is worn.

Despite the high qualities of a modern gas mask, none of them traps carbon monoxide. To protect against it, the GP-2 hopcalite cartridge is intended, which is screwed to the neck of the gas mask box. Inside the cartridge is a layer of hopcalite, which is a mixture of manganese dioxide (60%) and copper oxide (40%). Hopcalite is a catalyst that oxidizes carbon monoxide into less toxic carbon dioxide due to atmospheric oxygen. Above and below inside the cartridge are mixtures of hygroscopic substances (calcium chloride and silicogel), which absorb moisture from the air and protect hopcalite from damage (transformation of manganese and copper oxides into hydrates). The cartridge indicates its original weight (750-800gr.). A cartridge is considered used and unusable if its weight has increased by more than 20g. The hopcalite cartridge should be stored with necks tightly closed. GP-2 is not used when the concentration of CO 2 is more than 15% and when there is a lack of oxygen.

Special-purpose gas masks include gas masks with special helmet-masks ShMS, ShMS-1 and with a special helmet for

wounded in the head ShR-2.

The effect of a gas mask on physiological functions should be considered as a complex of influences, which consists of discomfort, harmful space and breathing resistance.

Gas mask discomfort is a combination of adverse effects on the body caused by wearing a gas mask helmet in a combat position. These include: mechanical compression of the soft tissues of the head; irritation of the skin of the face, decrease in the field of vision; violation of binocular vision; difficulty speaking; decreased audibility; turning off the functions of the taste analyzer and the smell analyzer.

Some of these phenomena are reduced or eliminated altogether by the presence of an obturator, an intercom and the design of glasses, as well as the correct selection of a helmet-mask and training to stay in a gas mask.

The harmful space of gas masks (RWP) is the free part of the mask space, i.e. the internal volume of all cavities under the body of the front part, where exhaled air with an increased content of carbon dioxide and water vapor is retained. When you inhale again, this air is mixed with the purified air coming from the filter-absorbing box. Reducing the volume of the harmful space is achieved by the design of the front part, the location of the inhalation and exhalation valves.

Resistance of gas masks (SP) to breathing occurs when air moves through the airways of a gas mask. It leads to a rarefaction of air under the helmet-mask at the inspiratory height and is characterized by a pressure difference between the external atmosphere and the free part of the mask space. Distinguish between static and dynamic joint venture. The static SP arises from the impact on the air movement of the mechanical parts of the gas mask: the gas mask and valve box, the connecting tube. It depends on the filtering surface and the density of the aerosol filter, on the filtration area and layer thickness, on the size of the activated carbon grains. Dynamic SP depends on the speed of movement of the inhaled air, which is determined by the amount of air consumed per minute. The emergence of a dynamic joint venture is due to increased pulmonary ventilation caused by the work performed or by a pathological condition.

Medical contraindications to the use of a gas mask can be divided into absolute and relative. Absolute contraindications include severe injuries and illnesses, in which, even at rest, the use of a gas mask is impossible or associated with great danger and risk. They are: penetrating wounds of the chest cavity and all head injuries associated with increased intracranial pressure, pulmonary, nose and stomach bleeding; unconsciousness; indomitable vomiting; convulsions; organic heart disease with symptoms of decompensation; sclerosis of coronary vessels with angina pectoris; severe diseases of the lungs and pleura (pneumonia, pulmonary edema, abscesses, exudative pleurisy, etc.); profuse nasal discharge, pronounced bronchospasm with lesions of OPA, etc.

Relative contraindications include diseases that allow the use of a gas mask for protection, but require caution or a certain restriction, and sometimes a prohibition of training. These include functional diseases of the heart and blood vessels, chronic diseases of the respiratory tract, kidney disease, etc. Patients in this category need to use gas masks only to save their lives in an infected environment.

Skin protection products, their purpose, classification

Skin protection products are designed to protect people from the effects of SDYAV, OV, RV and BS.

Skin protection products are divided into two groups:

a) insulating type (airtight) - OZK, KZP, L-1.

b) filtering type (breathable) - OKZK, impregnated uniforms and linen, KZS.

Insulating means are made of materials that do not allow a drop or a vapor of toxic substances to pass through and provide the necessary tightness and, therefore, protect a person.

The filter media are made of cotton cloth impregnated with special chemicals. A thin layer of impregnation envelops the threads of the fabric, and the space between them remains free. As a result, the breathability of the material is maintained,

while the OM vapors are retained when passing through the tissue. In some cases, neutralization occurs, and in others, sorption (absorption).

Skin protection products are classified by purpose:

a) combined arms - OZK, KPZ, OKZK, KZS, impregnated uniforms and underwear.

b) special - L-1.

Tactical and technical requirements for protective properties:

Means of skin protection should protect: from droplet liquid agents and their aerosols (mustard gas, soman); from OM vapors (mustard gas, soman) from light radiation with a pulse of up to 25 cal / cm 2; from fire mixtures for 10-15 seconds.

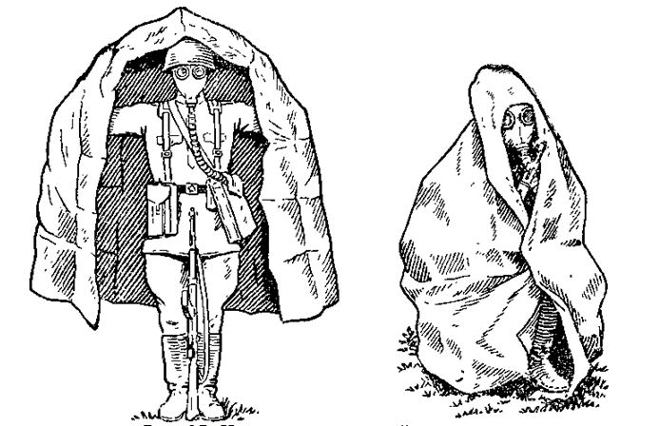

OZK (combined arms protective kit) is used by personnel of all branches of the military and special forces to protect against persistent agents in a droplet-liquid state, to protect the skin, uniforms and equipment from contamination with radioactive substances and bacterial agents.

The UGC includes:

Protective (combined arms) raincoat;

Protective stockings, protective gloves (summer and winter).

Protective (general) raincoat (OP-1), made of lightweight protective fabric with a butyl rubber coating. In the stowed position, it is rolled up in the form of a roll and worn on the back over the equipment. Protective stockings and protective gloves, packed in a special case, are worn on a waist belt on the right side.

OZK in combat conditions is worn in the following positions: in the form of a cape, a protective cloak is used in case of a sudden use of OV and BS by the enemy or in the event of a release of RV on the command "Gases, raincoats"; worn in sleeves, a protective raincoat is used when overcoming areas contaminated with OV, RV, BS, when conducting hostilities in an infected area, as well as when performing degassing, decontamination and disinfection work on the command "Cloak in sleeves, stockings, put on gloves"; overalls, a protective raincoat is used when carrying out rescue operations and evacuation measures in hotbeds of destruction with chemical weapons, when operating on terrain with tall grass, bushes and covered with a deep layer of snow at the command "Put on protective kit, gases".

KZP (protective film suit) is designed to protect personnel from drops and aerosols of organic matter, as well as to reduce contamination of military uniforms and equipment and radioactive dust.

KZP is used along with OZK. When providing the troops with KZP instead of the OZK set, the supply norms for skin protection are increased three times (instead of the OZK, 3 sets of KZP are issued).

The set includes:

Film protective raincoat - 1pc.

Film protective stockings - 1 pair

Protective gloves - 1 pair

Repair products - adhesive tape - 4 meters

KZP is intended for one-time use (it is not subject to special treatment in case of infection with OS and BS).

KZP suits contaminated with radioactive dust must be decontaminated to the permissible levels of contamination and can be reused. Weight 1 kg L-1 (light protective suit) is made of fabric based on polyisobutylene. L-1 refers to special protective clothing. It is used for prolonged action in contaminated areas, when working with organic substances, as well as when performing degassing, decontamination and disinfection works. The costume consists of a shirt with a hood, trousers with stockings, two-fingered gloves and a comforter. By design, suit L-1 is hermetically sealed, protects not only from droplets of organic matter, but also from vapors.

Characteristics of protective filtering clothing (OKZK, impregnated uniforms and linen, KZS)