Testing standards for protective equipment. Dielectric gloves: description, storage conditions, operating rules

For those who work with powerful electrical installations, you need personal protective equipment. To do this, use rubber boots, rugs, gloves. Rubber has a special composition that has increased electrical strength. Dielectric gloves protect the worker from electrical injury.

GOST for dielectric gloves seamless sets the necessary conditions to the material from which they are made, the production technology and the operating modes in which they are used.

Requirements for dielectric gloves

Dielectric gloves are made from natural rubber according to GOST 12.4.183-91 “System of labor safety standards. Hand protection materials. Technical requirements" .

Seam gloves are made by punching from pieces of sheet rubber. There is no GOST for them, but they are produced in accordance with TU 38305-05-257-89. The materials from which gloves are made must comply with quality indicators, the requirements of standards and provide protection against electrical injury.

Dielectric gloves release for electrical installations:

- with voltage up to 1000 V - as the main protective equipment (marked En);

- with a voltage above 1000 V - as an auxiliary protection when working with measuring rods, high voltage indicators, clamps (marked with EV).

Products must be at least 35 cm long. Glove width should be such that when working in the cold, you can pry warming gloves. Products must have a spacious trumpet so that it can be easily put on over clothes, including winter ones.

How to use protective gloves correctly

When using insulating gloves, you must act in accordance with operating rules:

- Before purchasing gloves and before starting work, it is imperative to pay attention to shelf life.

- You can only use dry products.

- It is necessary to carry out visual inspection and determine if there are any cuts, dirt, punctures on them.

- For checks tightness you need to fill the gloves with air.

- Check for stamp verification dielectric gloves;

- They must be put on to the full depth, the edge of the gloves should be worn over the sleeve of overalls. Forbidden wrap the edge of the gloves!

- To protect products from mechanical influences you can wear gloves made of leather, tarpaulin over them.

- Do not clean gloves with gasoline, acid or alkali solution. For this purpose, you can use only water, soap or soda.

- Storage rules do not store products near open flames, heating appliances. Storage temperature should be from 0 to +25 degrees. WITH.

Important! It is life-threatening to use dielectric gloves with an expired expiration date!

The material from which the gloves are made dry out, become brittle. As a result, the level of protection of gloves will be significantly reduced. fragile material can collapse at the wrong moment.

Checking dielectric gloves

During the entire period of operation, the products must pass periodic verification. To do this, they pour water into them and place them in a bath of water, leaving the upper edge of the gloves dry by 4-5 cm. Water is used at room temperature.

During the entire period of operation, the products must pass periodic verification. To do this, they pour water into them and place them in a bath of water, leaving the upper edge of the gloves dry by 4-5 cm. Water is used at room temperature.

Immersed in a glove electrode. Voltage is applied between it and the body of the water bath. If the current passing through the glove exceeds the norm, then it is subject to rejection. Verification period dielectric gloves - 1 time in six months.

We also advise you to find out what caused the high popularity

Dielectric gloves

Dielectric gloves are designed to protect hands from electric shock. When working in electrical installations up to 1000 V, gloves are used as the main electrical protective equipment, and in electrical installations above 1000 V as an additional.

In electrical installations, it is allowed to use seamless latex gloves (according to GOST 12.4.183-91 and TU 38.306-5-63-97) or gloves with a seam made of sheet rubber, made by punching (according to TU 38305-05-257-89). The length of dielectric gloves must be at least 350 mm. The size of the gloves should allow wool or cotton gloves to be worn under them to protect hands from low temperatures when servicing open devices in cold weather. The width along the bottom edge of the gloves should allow them to be pulled over the sleeves outerwear. Gloves can be five-fingered or two-fingered.

Rules for the use of dielectric gloves

It is forbidden to use gloves whose verification period has expired.

Before using gloves, make sure they are not damp or damaged. Check gloves for punctures by twisting them towards the fingers.

When working in dielectric gloves, the edges must not be turned up. To protect against mechanical damage, it is allowed to wear leather or canvas gloves or mittens over gloves.

Gloves in use should be periodically (according to local conditions) disinfected with soda or soapy water.

From personal experience work prefer seamless gloves. I used gloves with a seam, but either they were of poor quality, or this is a feature of all gloves with a seam, but they spread right on my hands and not only at the seams.

Dielectric Glove Tests

Once every 6 months, dielectric gloves must be tested increased voltage 6 kV for 1 minute. The current through the glove during the test shall not exceed 6 mA.

During the test, dielectric gloves are immersed in a metal vessel filled with water. Water temperature 25±10° C, water is poured inside the gloves. The water level outside and inside the product should be 50mm below the top edge of the gloves. The protruding edges of the gloves must be dry.

One terminal of the test transformer is connected to the vessel, the other is grounded. An electrode connected to ground through a milliammeter is lowered inside the gloves. One of the possible schemes of the test setup.

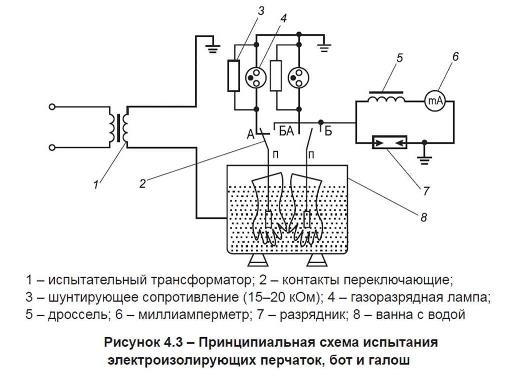

Rice. Schematic diagram of testing dielectric gloves, overshoes and galoshes:

1 - test transformer;

2 - switching contacts;

3 - shunt resistance (15-20 kOhm);

4 - gas discharge lamp;

5 - throttle;

6 - milliammeter;

7 - arrester;

8 - bath with water.

During the test, the switch is first set to position A in order to determine the absence or presence of a breakdown by signal lamps. In the absence of breakdown, the switch is set to position B to measure the current passing through the glove. A dielectric glove is rejected if the current passing through it exceeds the norm or sharp fluctuations of the milliammeter needle occur. In the event of a breakdown, the defective product or the entire installation is turned off. At the end of the tests, the products are dried.

Rubber dielectric protective equipment

Among the means that protect personnel from electric shock, the most widespread are dielectric gloves, galoshes, boots and carpets. They are made of rubber of a special composition, which has high electrical strength and good elasticity. However, special rubber is also destroyed by heat, light, mineral oils, gasoline, alkalis, etc., and is easily damaged mechanically.

Dielectric gloves

Dielectric gloves are produced in two types:

- dielectric gloves for electrical installations up to 1000 V, in which they are used as the main protective tool when working under voltage. These gloves must not be used in electrical installations above 1000 V;

- dielectric gloves for electrical installations above 1000 V, in which they are used as an additional protective tool when working with basic insulating protective equipment(rods, high voltage indicators, insulating and electrical clamps, etc.). In addition, these dielectric gloves are used without the use of other protective equipment during operations with drives of disconnectors, switches and other equipment with voltages above 1000 V.

Dielectric gloves designed for electrical installations above 1000 V can be used in electrical installations up to 1000 V as the main protective equipment. Gloves should be put on to their full depth, pulling the bell of the gloves over the sleeves of the clothes. It is unacceptable to wrap the edges of the gloves or lower the sleeves of clothing over them.

In electrical installations, gloves made of dielectric rubber, seamless or with a seam, five-fingered or two-fingered, can be used. In electrical installations, only dielectric gloves with marking according to protective properties Ev and En. The length of the gloves must be at least 350 mm. The size of dielectric gloves should allow knitted gloves to be worn under them to protect hands from low temperatures when working in cold weather. The width along the bottom edge of the gloves should allow them to be pulled over the sleeves of outerwear.

Rules for the use of dielectric gloves

Before use, the gloves should be inspected, paying attention to the absence of mechanical damage, contamination and moisture, and also check for punctures by twisting the gloves towards the fingers.

Each time before use, dielectric gloves should be checked by filling them with air for tightness, i.e. to identify through holes and tears in them, which can cause electric shock to a person.

When working with gloves, their edges are not allowed to be tucked. To protect against mechanical damage, it is allowed to wear leather or canvas gloves and mittens over gloves.

Gloves in use should be washed periodically, as necessary, with soda or soapy water, followed by drying.

During operation, electrical tests of dielectric gloves are carried out.

Gloves are immersed in a bath of water at a temperature of (25±15) °C. Water is also poured into the gloves. The water level both outside and inside the gloves should be 45-55 mm below their upper edges, which should be dry.

The test voltage is applied between the body of the bath and the electrode, which is lowered into the water inside the glove. It is possible to test several gloves at the same time, but it must be possible to control the value of the current flowing through each tested glove.

Dielectric gloves are rejected when they break down or when the current flowing through them exceeds the normalized value. A variant of the test setup scheme is shown in the figure.

Rice. Schematic diagram of testing dielectric gloves, bot and galoshes: 1 - test transformer, 2 - switching contacts, 3 - shunt resistance (15 - 20 kOhm), 4 - gas discharge lamp, 5 - choke, 6 - milliammeter, 7 - arrester, 8 - water bath

Norms and frequency electrical testing gloves are given in the "Instructions for the use and testing of protective equipment used in electrical installations" (SO 153-34.03603-2003).

At the end of the test, the gloves are dried.

Dielectric galoshes and boots

Dielectric galoshes and boots as additional protective equipment are used in operations performed with the help of basic protective equipment. At the same time, boots can be used both in closed and open electrical installations of any voltage, and galoshes - only in closed electrical installations up to 1000 V inclusive.

In addition, dielectric galoshes and boots are used as protection against step voltages in electrical installations of any voltage and any type, including overhead power lines. Dielectric galoshes and boots are worn on ordinary shoes, which must be clean and dry.

Dielectric shoes must be different in color from the rest of the rubber shoes. Galoshes and boots should consist of a rubber top, a rubber corrugated sole, a textile lining and internal reinforcing parts. Shaped boots can be produced unlined. Boots must have lapels. The height of the bot must be at least 160 mm.

The norms and frequency of electrical tests of dielectric galoshes and boots are given in the "Instructions for the use and testing of protective equipment used in electrical installations" (SO 153-34.03603-2003).

Rules for using dielectric shoes

Electrical installations should be equipped with dielectric shoes of several sizes. Before use, galoshes and boots should be inspected in order to detect possible defects (peeling of facing parts or lining, the presence of foreign hard inclusions, etc.).

Dielectric carpets

Dielectric carpets are used in rooms with increased danger and especially dangerous in terms of electric shock. At the same time, the premises should not be damp and dusty.

Carpets are spread on the floor in front of the equipment, where contact with current-carrying parts under voltage up to 1000 V is possible, during maintenance and repair of equipment, including in front of shields and assemblies, at rings and brush apparatus of generators and electric motors, at test benches, etc. .P. They are also used in places where switches, disconnectors, circuit breakers are switched on and off, rheostats are controlled and other operations are performed with switching and starting devices up to 1000 V and above.

Dielectric carpets should be at least 75 x 75 cm in size. In damp and dusty rooms, their dielectric properties deteriorate sharply, so insulating pads should be used instead of carpets in such rooms.

Dielectric carpets are manufactured in accordance with the requirements state standard depending on the purpose and operating conditions of the following two groups: 1st group - normal execution and 2nd group - oil and petrol resistant.

Carpets are made with a thickness of 6 ± 1 mm, a length of 500 to 8000 mm and a width of 500 to 1200 mm. Carpets must have a grooved front surface. Carpets must be of one color.

Insulating stand is a flooring, reinforced on support insulators with a height of at least 70 mm. Flooring with a size of at least 500x500 mm should be made of well-dried planed wooden planks without knots and slant. The gaps between the slats should be 10-30 mm. Planks should be connected without the use of metal fasteners. The flooring must be painted on all sides. It is allowed to make flooring from synthetic materials.

Insulating supports must be strong and stable. In the case of using removable insulators, their connection to the flooring must exclude the possibility of slipping of the flooring. To eliminate the possibility of overturning of the stand, the edges of the flooring should not protrude beyond the supporting surface of the insulators.

In operation, dielectric carpets and insulating supports are not tested. They are examined at least once every 6 months, as well as immediately before use. If mechanical defects are found, the carpets are removed from service and replaced with new ones, and the coasters are sent for repair. After repair, the stands must be tested according to the acceptance test standards.

After storage in a warehouse at a negative temperature, dielectric carpets must be kept in packaged form at a temperature of (20 ± 5) ° C for at least 24 hours before use.

Laboratory LabTestEnergo is a professional service related to electrical measurements and testing. We offer official services at an affordable cost with the issuance of an official conclusion. The list of services of the LabTestEnergo laboratory includes test checks of electrical protection equipment, including testing of dielectric gloves.

Tel. Manager: +7 495 777 10 76 (ext. 100) Vladimir

Email for order:

Testing dielectric gloves

To prevent injury to workers by electric current, a wide range of personal protective equipment is used - special protective clothing, helmets, belts, galoshes, gloves. Almost all of these items are made of special rubber, which is characterized by a high electrical strength and elasticity. But even special materials are destroyed over time and under the influence of mechanical, thermal, chemical factors.

Therefore, testing of rubber dielectric gloves is a mandatory procedure that allows you to ensure high level the safety of the working person.

In addition, when working in such gloves, you should follow the established rules. Before work, it is necessary to check the integrity of the gloves, the absence of moisture, dirt, punctures, which can cause electrical injury. When working with gloves, it is forbidden to tuck their edges, and in order to provide protection from the effects of mechanical factors, gloves made of leather or tarpaulin should be worn over dielectric gloves. After use, gloves should be washed with soap and water and dried thoroughly.

Testing of dielectric gloves is carried out in laboratories that have special permission Federal Service Russian Federation for Environmental, Technological and Nuclear Supervision.

During the test procedures, gloves are immersed in containers with water at a temperature of +25°C. Gloves should be filled with water to a level of 4.5-5.5 cm to the top edge. An electrode is placed inside a glove filled with water. A special voltage is applied between this electrode and the container body.

If a breakdown or deviation of the actual indicator of the electric current from the established standard is detected, the gloves are recognized as unsuitable for further use. Dry the gloves thoroughly after electrical testing. The norms and frequency of electrical testing of gloves are established by the provisions of the current instruction, which regulates the rules for testing electrical protection equipment.

Services of a certified laboratory in Moscow and the Moscow regionChecking dielectric gloves in Moscow at an affordable cost is offered by the laboratory of electrical measurements LabTestEnergo. For qualified testing, we have necessary equipment and certified personnel. You can order gloves tests on the laboratory website, as well as get advice by calling the indicated numbers. Our laboratory services are distinguished by the following advantages:![]()

- we work officially, transparently, with the provision of the necessary documentation;

- works are performed by certified specialists with more than 10 years of experience;

- laboratory equipment - high-precision modern equipment;

- competitive prices for testing dielectric gloves.

We work with departure to all districts of Moscow and the Moscow region.

When concluding an agreement with or with our company, testing (PPE) - FREE OF CHARGE*!

| Type of protective equipment |

Test cost 1 unit, rub. (VAT included) |

Periodicity | |

| Term - up to 5 days | Urgent trials (1 day) | ||

| Dielectric gloves (pair) | 195 | 295 | 1 time in 6 months. |

* Please call for details

Gloves are mandatory personal safety equipment for any electrician or worker associated with high-power electrical appliances (machinist, welder, car mechanic, etc.). We propose to consider which dielectric gloves are more effective - rubber or latex, how to check them for impermeability, where to buy these accessories and what their purpose is.

The production of dielectric gloves is considered one of the most affordable types of business, because very cheap materials and the simplest processing methods are used. For manufacturing, latex, silicone or rubber is taken, depending on the purpose. After that, the cheese is melted at a high temperature, mixed with some additives and lowered to an automatic line. Here the working system is very similar to steel casting. Must be filled with liquid dielectric solution special form, after which future gloves are placed on a special cooling mechanism.

It should be noted that the standards by which the composition is checked, marking and verification at the end of work are prescribed in GOST about dielectric punched gloves (okdp is taken as the basis, see photo).

Here, not only cooling is performed, but also the strengthening of the structure with the help of a contrast temperature. Hot rubber molds are lowered for a certain amount of time (3-5 seconds), in cold water, and so hundreds of times, until the material cools and takes the shape we need.

Further, if necessary, gloves are insulated. It should be noted that the absence of insulation is not a disadvantage, and the price of such dielectric seamed and seamless gloves is much lower than for models with fabric upholstery. But it is very inconvenient to work in winter, especially in extreme conditions, in addition, a greenhouse effect can form, which could have been avoided with a fabric layer.

What are gloves

Depending on the maximum allowable voltage level, there are such types of protective gloves:

Let's consider each type separately.

Class 00- these are the weakest dielectric protective safety gloves, mainly latex is used for their manufacture, accounting and testing are carried out on special equipment. They are designed to work on low power installations, these are household electrical appliances.

Class 0– these gloves can be used without additional protective equipment for work on electrical installations, with voltages up to 1000 volts. This can be relatively weak production mechanisms and lines.

For more serious work, say, on medium-power machine equipment, gloves with a tolerance of up to 7500 volts are used, this is class 1.

Class 2- these are in most cases, dielectric silicone gloves, tested for protection against voltage of 10,000 volts. This is one of the most widely used means of protection, because. the scope of application is very wide: powerful machine tools, automotive equipment, etc.

The remaining classes can be attributed to special protective accessories, these are means of protection against high-power loads (industrial electrics, machine tools, etc.).

When you have chosen the right type of gloves, be sure to read the description given by the manufacturer. Sale of accessories is carried out in any electrical shop, on the market or from the manufacturer. Average cost per big cities(Moscow, St. Petersburg, Tolyatti, Ulyanovsk, Khabarovsk, Kharkov, Yaroslavl, Rostov-on-Don, Petrozavodsk, Omsk, Perm, Novosibirsk, Nizhny Novgorod, Krasnoyarsk, Kazan, Kyiv, Yekaterinburg, Dnepropetrovsk, Voronezh, Volgograd, Vladivostok, Almaty) - ranges from 100 rubles and several thousand (although, for example, the Volga plant offers us gloves from 80 rubles per pair).

When buying, check the product passport and its characteristics, the document with the price or the price list is not so important here, believe me, it is much more dangerous to buy a fake for imported gloves made of dielectric materials, which may simply not withstand the specified number of volts. We advise you to give preference to such brands as hivamat, knipex, azri, aktau, you can also order them online by visiting online stores.

Check (test) of dielectric gloves

Remember, during operation and when buying gloves, be sure to check the integrity of the material. This can be done for free: inflate the glove with air, then tightly close the main hole, and lower the glove under water. If there are no air bubbles, then the glove is completely intact, but as soon as this phenomenon is noticed, it is urgent to change the protective accessories.

There is another way to more serious check, accessories with high classes (from 2) need it. We fill a metal container with water, the water must be at a temperature of 37 degrees, a deviation of 5-7 degrees in both directions is allowed.

The quality certificate of conformity describes in detail in which cases dielectric gloves are not suitable for work (no additional verification is needed here):

- Hole, cut or tear;

- The presence of a foreign object in the structure;

- Rotten areas;

- The gloves are too soft, hard, sticky or inelastic.

Sometimes manufacturers indicate unreliable data in the instructions regarding throughput, here you need to test dielectric gloves as follows.

We lower the mittens into the water, then fill it with water by about 5 centimeters, and connect our home-made tester to the test transformer. And we apply voltage, 6 kW. You need to connect as follows:

- The transformer output is connected to the tank, we ground it;

- We attach the second transformer contact to the switch, which has several positions (as an example, we took two). Figure testing gloves with a transformer

- Set the switch positions. The first option should be connected in this way: transformer installation + lamp + electrodes, and the second option: transformer installation + especially sensitive ammeter-electrodes.

The rubber mat, helmet and sleeves are also checked.

Where can I check dielectric gloves, say, electrosoft (electrosoft), except at home? Each city has a special laboratory (in Moscow it is MIEE), where the guest verification technology is fully maintained, the cost of this procedure is about 100 rubles, the average duration is half an hour.

Storage rules

It is very important to observe the operating conditions for the use of protective accessories. Thus, their durability is significantly increased. What care do dielectric gloves, boots, galoshes, rugs, etc. need?

- Mittens should be stored in a dark and very dry place;

- The place where you can hang dielectric gloves ev, en or tu should be as spacious as possible, because. accessories often leave traces of chemical compounds, gases, oxides of various metals;

- Avoid hitting direct sun rays on rubber, latex and silicone. Especially harmful is also the fluorescent glow;

- How to properly store gloves: wipe them dry natural fabric. Place the rubber insulating gloves in the glove box, fingertips up, and hang in place. You can not keep the mittens in a horizontal position, twisted or wrinkled. Glove storage pattern

- carefully select your size;

- any dielectric gloves have an expiration date (the instructions for the selected series will help you with this), also buying accessories in bulk (say, a set) can save a lot;

- most often in a set or kit there is also a first aid kit, a helmet and cotton gloves;

- we advise in any case to visit an electrical shop for these purposes;

- when returning, draw up a protocol, it will help you receive compensation for low-quality electrical goods that could damage your health (in St. Petersburg, fines reach tens of thousands of rubles);

- Gloves must be stamped by the manufacturer.

- Composition: description of the painting And

- “The work of the master is afraid The lexical meaning of the proverb is the work of the master is afraid

- Deep knowledge The language of the people is a mirror of their soul, cultural heritage

- How to switch to a raw food diet without harm to health Green buckwheat, avocado and cucumber salad

- Unique honeysuckle berry: beneficial properties and contraindications for humans, norms and uses

- Subtleties and rigor of raw food diet Raw food diet for weight loss: result - before and after photos

- Almonds: benefits and harms to the human body, where they are used, and how to eat Almonds, benefits and harms to the human body

- Collection of ideal social studies essays

- Is the SmartScreen filter different from the pop-up blocker?

- Windows system recovery from USB flash drive, DVD drive

- How to put a password on a flash drive

- How to remove the service pack if the system cannot boot

- Where are screenshots saved?

- Where are they located and how to change the download folder in the Yandex browser

- How to check a laptop battery - detailed instructions

- Display shortcuts on windows 10 desktop

- Programs for cleaning RAM

- rundll error: The specified module could not be found at startup

- Why did the windows 10 icon disappear?

- LAN setup