Fleece types. What is fleece? What properties does this material have?

Fleece gains in modern world increasingly popular. Despite its relative youth (it was invented a little over 30 years ago), the material quickly gained its fans and is widely used in the production of clothing and home textiles.

Fleece is a non-woven soft fleecy material of synthetic origin. Composition: polyester fibers.

There are many varieties of this fabric. They differ in both density and appearance. The first indicator can vary from 100 to 600 g/m².

It may be the same in appearance on both sides or differ in pile height and fluffiness.

Production

First, a dense knitted fabric is made from polyethylene terephthalate fiber, which is subjected to wet and heat treatment. The next step is the actual creation of fleece fabric. To do this, the canvas passes through a machine equipped with rollers with many hooks. They pull strands of fibers to the surface without compromising the integrity of the fabric. The result is a pile of polyester fibers with many air-filled pores.

Then the resulting tissue undergoes anti-pilling treatment. This prevents pilling from appearing when using the products. The last stage Fleece is treated with special solutions. They give the fabric special properties, for example, a water-repellent or antibacterial coating.

![]()

The raw materials used for the production of fleece are completely synthetic fibers, both primary and recycled (plastic bottles, film). Fleece has no natural analogue. In some ways, products of this type have replaced woolen ones, but their properties are completely unique and not identical to wool.

Fleece is widely used for the manufacture of sportswear and children's clothing (sweatshirts, overalls, pants), thermal underwear and underwear, accessories (mittens, hats, socks), as insulation for outerwear(jackets, trousers, hats), as well as home textiles (robes, blankets, bedspreads).

Description of fabric types

They differ according to several criteria.

By specific density:

- microfleece is a thin fabric with a density of less than 100 g/m². It is usually used to make underwear, thin underwear, and home clothes;

- low-density polar fleece - slightly denser than micro-fleece (100 g/m²), used for thermal underwear, leggings, thin sweatshirts;

- medium-dense - the most popular look density 200 g/m², used in the production of children's clothing, hats, scarves, mittens, socks;

- dense (300 g/m²), this thickness is used for very warm clothing, as well as for the production of home textiles;

- ultra-dense polar fleece (400-600 g/m²) – used for the production of special (tourist, for example) clothing and equipment.

By processing method:

- anti-pilling;

- antistatic;

- water-repellent;

- anti-flammable.

Treatment of the fabric with various compositions is designed to improve performance characteristics. It can be bilateral or unilateral, processing methods can be combined with each other.

By composition:

There are also disadvantages:

- subject to electrification;

- highly flammable;

- inexpensive options quickly roll off, pellets appear on the surface, and the product loses its properties, performance characteristics noticeably deteriorate.

Manufacturers, for the most part, successfully neutralize all these shortcomings by treating them with special fire-resistant, anti-pilling and antistatic compounds. Despite the fact that all fabrics are of synthetic origin and are made from the same type of raw material, different technologies are used in production and the materials have different characteristics.

Comparison of fleece with other fabrics of synthetic origin

Material characteristics

Product care is easy

- Hand and machine washable (mode for delicate fabrics) in cool water (not higher than 40 degrees);

- available for sale special means for washing fleece products, but this fabric is unpretentious - any liquid detergent and even ordinary soap will do, but it is not recommended to use powders;

- Do not dry it on the radiator, do not twist the product - just hang it and let the water drain - it dries very quickly;

- Do not iron. Already at a temperature of 60 degrees, the fibers melt and irreversibly lose their qualities.

Currently, a huge amount of modern materials are used for sewing clothes and home textiles. In all this diversity, fleece fabric occupies not the last place. Although it is synthetic, it is a very high-quality material that, compared to others, has many undeniable advantages. How it differs from others, what it is like and what its advantages are - this is exactly what will be discussed in our article.

What is fleece fabric

The name of this material was formed on the basis English word“fleece”, which means “ sheep's wool, fleece." This circumstance can easily mislead regarding its structure. Therefore, we immediately note that fleece fabric does not contain either sheep or any other natural wool. Typically, such material is made from unstructured polyester, to which sometimes non-structured materials are added. a large number of other synthetic ones. Fleece fabric differs from others in the peculiarity of its weaving: the base and the pile are combined into one whole. Lycra fibers are often added to improve quality. Depending on its thickness, fleece fabric (photo below) is divided into thin, as well as low and medium density.  In addition, this material can be single-sided or double-sided. In the latter case, the top layer is designed to protect against wind, and the inner layer is designed to create comfortable warmth. Also worth mentioning is a fleece called windblock. It consists of two layers of medium density, between which there is a special membrane for protection from wind.

In addition, this material can be single-sided or double-sided. In the latter case, the top layer is designed to protect against wind, and the inner layer is designed to create comfortable warmth. Also worth mentioning is a fleece called windblock. It consists of two layers of medium density, between which there is a special membrane for protection from wind.

Benefits of fleece

Products made from this are distinguished by their durability, lightness and softness. This material is quite pleasant to the touch and retains heat perfectly. In this respect, it can easily compete with wool. Fleece fabric is famous for its excellent breathability (816 dm 3 / m 2 * C) and high hygroscopicity (0.8%). This means that things made from it allow the body to “breathe” and at the same time almost do not absorb moisture. Despite the fact that fleece fabric is a synthetic material, it does not cause allergic reactions or skin irritations. Therefore, children's things are often made from it. Due to its ability to retain heat even when wet, this material is often used for sewing all kinds of outer jackets, sweaters, sweatshirts), scarves, hats, costumes and toys for pets, rugs and blankets, and is also used as insulation for winter clothes. If we add that this fabric dries very quickly, does not fade and is machine washable, it becomes clear why Lately this is how its popularity in the textile market increased.

How much does fleece fabric cost?

The price of this material largely depends on the tailoring features, density, brand, and country of manufacture. Most famous brand This type of fabric is Polartec from Malden Mills. Interestingly, fleece was invented by specialists from this particular company (1979), for which they received the Nobel Prize. In addition to the USA, the production of this fabric is highly developed in Canada and Germany. However, let's get back to the cost. In online stores, the price varies from 100 to 500 rubles per linear meter. The average cost is about 250-300 rubles/linear meter.

Fleece is an artificial analogue of sheepskin. The dense, lightweight, soft-to-touch material is obtained from polyester knitted fabric by pulling the lint out of it using special equipment. Varieties of the basic technology allow several modifications of the canvases.

How and what is fleece made from?

There is a unanimous opinion about the composition of the fabric. It is a polyester material made by copolymerizing terephthalic acid and ethylene glycol. The remaining definitions contain different information. You can come across the adjectives “knitted”, “non-woven” or the paradoxical phrase “non-woven knitted fabric”.

It's useful to remember the basics.

- Textile materials made through weaving are called fabrics. Threads and/or fibers are woven into fabrics.

- Textile materials obtained by weaving loops of threads are called knitwear.

- There are textiles obtained by bonding layers by mechanical, chemical or combined methods. Such fabrics are called non-woven.

Fleece is a knitted material. The main fabric is knitted from loops formed by polyester threads.

According to information from a number of sources, inventors from the Malden Mills company were awarded Nobel Prize in chemistry. Careful study of the list of laureates awarded this honorary award for research in the field of chemistry, physics in 1979 and adjacent years, the information was not confirmed. In 1979, the prize was awarded to highly respected scientists who were not related to this topic. This development obviously cannot apply to physiology and medicine, nor to literature. Consequently, there was no bonus, which does not diminish the importance of the work.

Fleece fabric in bluish tones

Fleece fabric in bluish tones Polar fleece is the first name of the material, invented by Malden Mills in 1979. The presence of the word polar in the title is not entirely clear. The polymer is not polar. Apparently, the material was named because of the diametric arrangement of the pile, on both sides. There is such a translation for the word polar.

Malden Mills was founded in 1906. At first they made clothes for workers, then for the military, constantly improving technology. The appearance of the polar fleece material has made manufacturers leading among all enterprises producing textile products. A huge number have appeared new clothes, which some called polar, others called fleece.

Following a reorganization in 2007, the company became Polartec, LLC. Currently, more than 300 varieties of products are produced under this brand, in addition to numerous followers in other companies. Manufacturers do not disclose technological details. The basic approaches are clear.

- Polyesters for fleece can be obtained from primary monomers or from secondary products such as plastic bottles. Threads are drawn from molten polyethylene terephthalate, passing the mass through thin holes - dies. This method is called extrusion. One thread can contain up to 250 fibers.

- The fabric is knitted using conventional machines. Then it is washed, painted, impregnated with compounds to reject water, and cut into pieces.

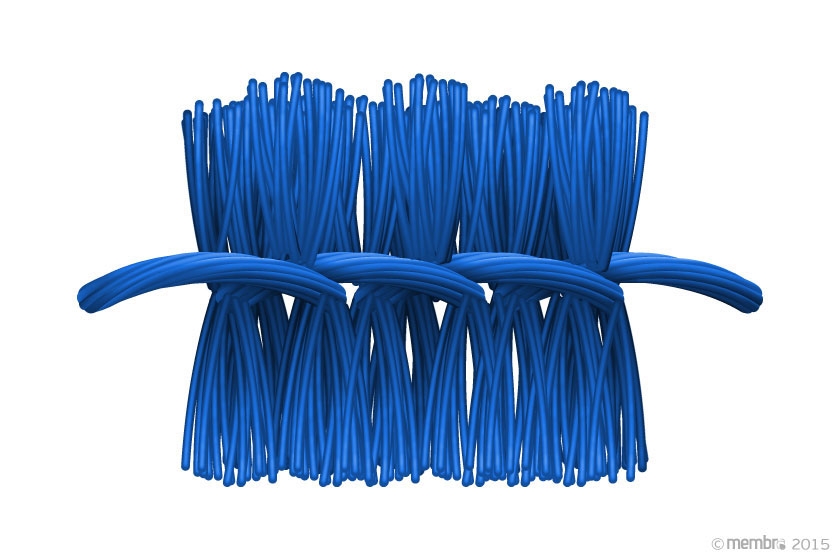

- The knitted polyester fabric is passed through equipment with brushes, which pull out the loops and fluff them up. As a result, lint appears on the surface. Sometimes they write that the pile on the fleece is glued. Perhaps someone is already gluing it. In true fleece, the pile is integral with the warp threads.

- First, the canvas is rolled over the bristly surface with one side, then the other. The result is a huge number of loops on both sides. The loops contain air. This air-polymer cushion ensures the softness and thermal protection of the material.

There are many options for implementing fleece production technology. The basis is taken from threads of different thicknesses, differing in the number of fibers. The fabric is knitted in various modes. The height of the drawn loops and the methods of subsequent processing of the material vary. The resulting products are varied. The basic qualities are the same.

Characteristics of materials and products

- Fleece fabric is very dense (from 100 g/m2 to 600 g/m2).

- Material with a minimum density is sometimes called microfleece and is used for the production of fine linen.

- Thin jackets, leggings, and thermal underwear are made from fabric, which is called “polar fleece,” with a density of 100 g/m2 to 200 g/m2.

- The most common is fleece with an average density of 200 g/m2. It is used to make hats, socks, scarves, mittens, and clothes for children.

- Fleece with a density of 300 g/m2 has proven itself well in home textiles and winter clothing.

- The thickest fabrics (up to 600 g/m2) are used to make clothes and equipment for tourists, climbers, and supporters of extreme forms of recreation. In such products, in addition to fleece, other materials are used to obtain a multi-layer coating.

- Fleece differs in appearance. The height of the pile on one side may be greater than on the opposite surface.

- Additional processing may include protection from:

- ignition;

- excess moisture;

- formation of pili (pellets);

- accumulation of static electricity;

- microbial proliferation.

- Fleece differs in dyeing methods. There are canvases painted smoothly, or material with a pattern - print.

The main advantages of fleece

All products are characterized by the following qualities:

- elasticity (stretches easily);

- elasticity (products keep their shape for a long time);

- ease;

- thermal protection;

- breathability;

- strength;

- abrasion resistance;

- ease of care;

- reduced ability to cause allergic reactions.

Children's fleece clothing

Children's fleece clothing IN various sources There is information about the tendency of the material to ignite, dust, electrify, and pile formation. Well-known experienced manufacturers have long learned to cope with these features of the original canvases by carrying out special processing. The presence of such defects in a product in most cases indicates unprofessional attempts to make the material. The companies Patagonia, North face, Eddie bauer, Lands end, Llbean, of course, are the founders of production - Polartec produce products positive traits which has been confirmed by many years of practice.

How to care for fleece products

- Such clothes should be washed in a gentle cycle at low drum speeds at a temperature not exceeding 40°C. It is better to use liquid laundry detergents. They are easily distributed throughout the entire volume of water and wash dirt off the fibers well.

- Do not add stain removers, bleaches, or conditioners. It is not necessary. The material washes off easily.

- It is recommended to rinse products thoroughly. A large amount of lint can trap detergent molecules.

- The material must be wrung out easily. You can allow the water to drain spontaneously by placing the product on hangers. The water dries out quickly.

- There is no need to iron the fleece. It looks great once dry.

- If the clothing contains other textile materials, the manufacturers' recommendations should be taken into account when caring.

Fleece is a material for sportswear, homewear, and everyday textiles. The combination of aesthetic and practical qualities makes it irreplaceable, loved and in demand by many consumers.

What is fleece, how and why does it warm, what are its advantages and disadvantages compared to traditional materials such as wool and cotton?

Fleece(English fleece - sheepskin) - this is the name for synthetic knitted materials made from polyester fiber(polyester), specially treated to significantly reduce thermal conductivity. The name “polar fleece” was coined by the company in 1979 for the material it invented. Since then, a whole class of clothing has come to be called this way. And in the tourist environment you can often hear the names “polar” and “fleece”.

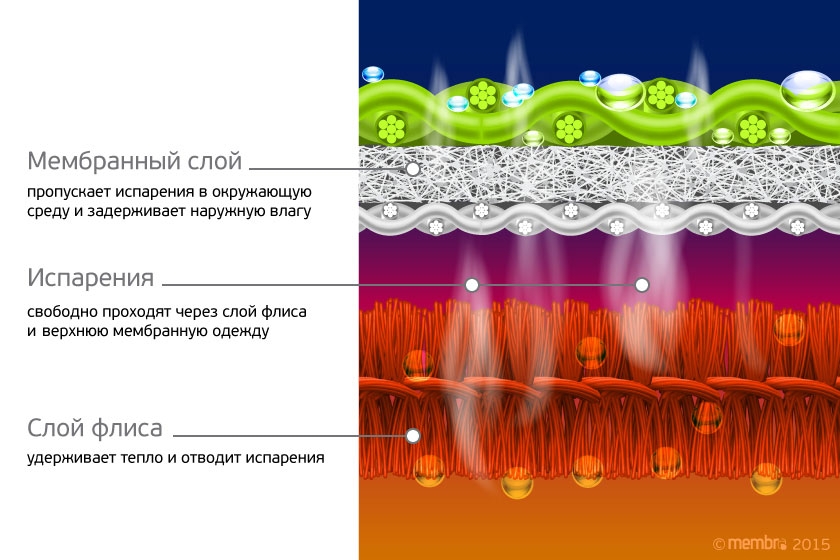

Fleece fabric is used to make jackets and trousers, hats, gloves and other products used to retain heat. In the modern outdoor industry, products made from this material are often used as a second, warming layer in a three-layer clothing system. Polartec is considered the leader among manufacturers ®.

In addition to good heat-saving characteristics, fleece is light, soft, pleasant to the touch, does not wrinkle and has high hydrophobicity, that is, its fibers do not absorb water. Therefore, fleece products dry quickly and remove moisture well from the surface of human skin into the surrounding space.

How and why fleece works

In the article we said that warm clothes- these are clothes that create between the surface human body And environment a zone with a low thermal conductivity coefficient. We also mentioned that according to this indicator, the best heat insulator is air. Therefore, clothing that retains a layer of still air near the human body can be considered warm. Fleece clothing warms precisely because this material is able to “bind” and hold a large amount of air in its structure.

The structure of synthetic “polar sheepskin” is similar to the structure of wool, that is, it has a large number of thin, complexly intertwined fibers that form countless air pockets. The air in these pockets practically does not circulate or mix. And the thicker the fleece fabric, the more air is retained in its air pockets - and the warmer the clothing.

Typical structure of double-sided fleece fabric

The second important property of fleece is its hydrophobicity. In Russian it literally sounds like hydrophobia, but we are not talking about illness, but about health, so we will leave this term without a literal translation.

The hydrophobicity of fleece is the property of polyester threads not to absorb moisture, that is, not to become wet and not to retain water in their microstructure. This quality determines its main operational characteristics:

Fleece products dry very quickly.

The fleece layer easily allows evaporation from the human body to pass through it and remains dry if further evaporation of moisture is not prevented by the top layer of clothing.

If the fleece fabric gets wet and water fills its air pockets, displacing air from there, the warming effect is still preserved. This is due to the fact that water does not circulate in the fleece, and therefore does not participate in heat transfer.

Interaction of fleece and membrane layers of clothing

Advantages and disadvantages of fleece

To evaluate the advantages and disadvantages of fleece, it is worth comparing it with other materials traditionally used to make warm knitwear. Natural ones include cotton and wool.

Heat saving

Wool and fleece are quite similar in their vapor permeability and heat-saving characteristics, both in dry and wet states. This is due to the similarity of their structure. Both materials heat well when dry, lose their heating characteristics slightly when wet and regain them when dry. However, the rate of complete drying of fleece is approximately ten times faster than that of wool. It is this indicator that is decisive when choosing between wool and fleece. If in difficult weather conditions a wet fleece jacket can still be dried, for example, during an overnight stay on a hike, then this will no longer be possible with a woolen sweater.

Cotton products retain heat worse than wool and fleece, and when wet, cotton transports heat so effectively that there is a serious risk of hypothermia, that is, hypothermia.

Hydrophobicity

According to this indicator, wool and cotton are not competitors to fleece. Wool absorbs about thirty times more moisture than fleece, and therefore takes much longer to get rid of this moisture. Wet wool acquires a rather unpleasant odor. And hydrophilic—that is, water-loving—cotton, when wet, also begins to effectively cool the surface of the body.

Tactile comfort

Fleece and cotton are hypoallergenic and do not cause problems when in contact with the skin. Fleece clothing, due to its softness and smoothness, is even pleasant. Wool can cause problems for the skin. It pricks, causes irritation, itching and sometimes allergies.

Weight

Both dry and wet, fleece weighs the least. In contrast, both wool and cotton become quite heavy when wet. The lightness of fleece is an important property appreciated by outdoor lovers. This allows the use of fleece products in conditions where saving weight is one of the important tasks.

Fire resistance

Properly processed fleece does not burn, but only melts. But even this rather relative disadvantage is absent from wool and cotton. When hot coal hits them, holes that are melted and charred at the edges do not form.

Electrification

Unlike cotton, which is completely indifferent to static electricity, wool accumulates it. But the leader here is fleece. It is highly electrified, which creates many problems. When removing fleece clothing, static electricity discharges can create discomfort.

Biological stability

It is absolutely known that fleece, unlike wool, is not at risk of being eaten by moths. But the debate about the bactericidal properties of these materials does not subside. Some believe that wool is better than synthetic fibers in resisting bacteria that decompose sweat and thus create an unpleasant odor. Others believe that skin irritations caused by fur may contribute to the development of infection. As a rule, leading manufacturers of polyester insulation treat their products with silver salts, which inhibit the growth of bacteria that cause the smell of sweat.

Therefore, when choosing the most biologically friendly insulation, the decisive factor is still individual characteristics the body - its microflora, metabolism, age and immunity.

What kind of fleece is there?

The characteristics of clothing based on fleece materials have made it very popular among outdoor enthusiasts. However, there are many active people, and they are engaged different types activities - from hiking with a dog to mountain climbing. Each of them ideally requires not some average fleece jacket, but a product specially designed for specific operating conditions. Of course, manufacturers could not miss this opportunity, as a result of which quite a few varieties of fleece appeared, which differ from each other in density, thickness, texture, number of layers, types of processing of the front and back surfaces.

The main characteristic of fleece, indicating its heat-saving functions, is specific density, which can be from 100 to 600 g/m2. Shirts, sweatshirts and other relatively lightweight products are made from low-density fabric, and densities from 200 g/m2 are already well suited for outdoor-class products, which can be used both independently and as an insulating layer in multi-layer clothing. Waterproof and windproof membrane materials are often found in modern fleece jackets. Fleece can also be used as an insulating inner lining in clothing made from other textile materials.

How and when to wear fleece

The main property of fleece clothing is insulation. Therefore, it should be worn in the same cases as any other warm knitted clothing, such as a woolen sweater or jumper. If, when going for a walk, you suspect that the air temperature is slightly lower than comfortable and there is a risk of freezing, then a fleece jacket is what you need. However, remember that it will not protect against biting winds unless it is designed with a windproof membrane. Also, don't expect this jacket to keep you dry in heavy rain. Despite having some water-repellent properties and being treated with DWR treatments, fleece is not designed to protect against rain.

Another important quality of this material is its hydrophobicity combined with breathability. This allows you to use fleece clothing for active outdoor activities. Even if you sweat, the moisture will not stay on the surface of your body for long, and the fleece itself will dry out very quickly, and during the drying process it will not stop warming you. If you add to this lightness, softness and wear resistance, it becomes clear why fleece clothing has gained such wide popularity among outdoor enthusiasts. It is during active activity on outdoors, on hikes and expeditions, all the unique properties of “synthetic wool” are fully revealed.

However, when using fleece clothing, it is worth remembering that the best way its qualities are manifested in combination with properly selected thermal underwear, and in case of rain, with outer waterproof clothing.

How to care for fleece

When caring for fleece clothing, you must first comply with the requirements of the manufacturer of this product. However, fleece itself is not difficult to care for. It requires gentle washing modes at a water temperature of no higher than 40 ºС. Some manufacturers recommend turning the product inside out before washing. Machine washing is carried out at low speeds of the centrifuge or in the outdoor mode, if available in the program washing machine. It is better to use liquid detergents. Do not use bleaches, conditioners or stain removers.

After washing, fleece clothing should be rinsed thoroughly in clean water to remove detergent residues. Fleece dries quickly, so you don't have to wring it out. After the water has drained from it, you can hang it in the air, where it will dry very quickly. If the product contains other materials or membranes in addition to fleece, follow the manufacturer's instructions or follow the general requirements for washing outdoor clothing. Do not iron fleece clothing.

Summary

- Fleece clothing can protect against wind and moisture if it has a membrane in its design.

Fleece is an insulating and moisture-wicking synthetic material.

This " faux wool» light, strong, durable and easy to maintain. Fleece clothing warms well, effectively removes fumes from the body, dries quickly, does not cause allergies and does not wrinkle.

Fleece can be used either separately or in a three-layer clothing system as a second, warming layer.

The name of fleece fabric comes from the English. fleece - pile, wool. Unlike natural wool fabrics, fleece is synthetic fabric, in the manufacture of which polyester and other artificial threads are used.

However, like wool, fleece has the ability to retain heat well, and, in addition, it is lighter, unpretentious, and has moisture-repellent properties.

Historical reference: Fleece fabric was first produced at the end of the 20th century. The discovery was awarded the Nobel Prize, and for good reason: the material turned out to be a worthy replacement for wool - warm enough, but at the same time allowing the body to “breathe”.

Fleece is a non-woven material made from polyester. Using special machines, small loops are created to create backcombing and many breathable pores. The fabric is processed in production to reduce the flammability of the material and prevent the formation of pellets.

Products made from fleece do not shrink or distort and do not shrink, so the fabric does not require preliminary decating. Despite this, fleece has excellent stretch, does not fade, and has good dyeability.

Types of fleece

Fabric varies in density, texture, composition and many other parameters.

Fleece is distinguished by density:

- Thin (100 – 200 g/m2) – used mainly for the manufacture of thermal underwear;

- Medium density (200 - 300 g/m2) - good for sewing clothes for children, gloves and hats.

- Dense (300-400 g/m2) - well suited for blankets and outerwear.

- Very dense (400-600 g/m2) - used for the production of equipment for tourists.

Types of fabric depending on composition and manufacturing technology:

Velsoft (microfiber)– knitwear, characterized by sufficient strength, softness and long pile (250-310 g/m2). Quite fluffy but light fabric.

Mahra (frote)– a natural type of fleece, made from cotton or linen. Terry is a fabric with double-sided pile, which is formed by tiny loops. The longer the pile, the higher the density of the fabric (usually from 160 to 180 g/m2). This fabric is soft and pleasant to the touch.

Footer– the fabric contains cotton, so the material absorbs the flag well and is durable. It has a fleece on one side, which makes it warm, but at the same time thin and soft.

Velours– also made with the addition of cotton. Density can vary from 220 to 420 g/m2. The canvas is covered with many fibers ranging from 3 to 7 millimeters in length. It is wear-resistant, retains heat, does not wrinkle or form wrinkles.

Using fleece

- Thanks to unique properties, the material is widely used for making sportswear. Things made from such fabric are quite elastic and warm - for this, fleece products are appreciated by tourists and lovers of hunting and fishing.

- Popular casual wear from fleece - socks, thermal underwear, bathrobes, vests, sweatshirts, etc.

- Due to its softness, the fabric has become widespread in the manufacture of children's clothing - overalls, hats and mittens. In addition, synthetics are a poor environment for the proliferation of bacteria and microorganisms.

- Home textiles include cozy blankets, bedspreads and fleece blankets.

- As one of the most practical and undemanding fabrics, fleece is often used for upholstery and upholstery of furniture, pillows and mattresses - the material easily allows moisture to pass through without absorbing it, so stains and stains will rarely appear on the upholstery.

- Delicate pile, bright and attractive colors make fleece a popular material for making soft toys.

Advantages and disadvantages

The advantages of fleece fabric undoubtedly include:

- Hypoallergenic;

- Thermal insulation properties even when wet;

- Aeration (the ability of fabric to “breathe”);

- Ease;

- Relative strength and wear resistance.

Among the disadvantages are:

- Susceptibility to electrification;

- Absorbs dust.

Caring for fleece products

Important: Fleece products cannot be ironed - at temperatures above 60 degrees the fabric loses its properties, and synthetic fibers melt easily.

Fleece items can be stored folded or on hangers.

Cleaning toys:

Small fleece toys can be cleaned by dry cleaning:

- place the product in a plastic bag, add baking soda (about a quarter cup for a medium-sized toy);

- shake the bag for a minute;

- Take the toy out and brush it with a brush to remove any remaining soda and dirt.

- Mars 4th planet of the solar system

- Human organ systems

- Experimental methods for recording elementary particles

- What is the Swedish match famous for?

- The best self-propelled howitzers Russian artillery

- Fedor Petrovich Litke: second circumnavigation of the world

- The first pharmacy was opened

- Wonderful traveler and scientist Fedor Petrovich Litke Stamp issued in honor of the Litke expedition

- Union of the Livonian Order with the Teutonic Order

- Pizza dough - secrets of Italian cuisine

- How to make shortcrust pastry baskets

- Zero calculation for insurance premiums: do you need to submit it to the tax office?

- How to pay transport tax for legal entities

- Card for individual accounting of the amounts of accrued payments and other remunerations and the amounts of accrued insurance premiums Card for insurance premiums per year

- Peculiarities of calculation and payment of vehicle tax by legal entities Increasing transport tax coefficient - what is it?

- Error when filling in Contour

- Desk audit: developments

- Conditions for performing the stern experiment

- System status and processes

- Alexey Sergeevich Obukhov development of student research activities