What means of respiratory organs are used. Respiratory protection

The most reliable means of protecting the respiratory organs of people are gas masks. They are designed to protect against getting into the respiratory system, on the eyes and face of radioactive, poisonous substances and bacterial agents (pathogenic microbes and toxins).

Filtering gas masks. A person wearing a filtering gas mask breathes pre-cleaned outside air. The main filtering gas masks are civilian Gas masks GP-5(Fig. 1), GP-5M, GP-4u(Fig. 2), children Gas masks DP-6, DP-6M, PDF-7, PDF-D, PDF-Sh AND Protective camera for children (KZD-4). The principle of operation of filtering gas masks is based on the fact that the air used for breathing is pre-cleaned (filtered) from harmful impurities,

The filtering gas mask consists of a filtering-absorbing box and a front part. In addition, the gas mask kit includes:

A bag for a gas mask and a box of anti-fog films or a special pencil used to prevent glasses from fogging up.

Gas masks GP-5 and GP-5M are equipped with a filter-absorbing box of small size; the front part is represented by a helmet-mask; In the GP-5M gas mask, the helmet-mask is equipped with a membrane box, which houses the intercom. Filtering-absorbing box of a gas mask GU-4u of a larger size; it is connected with the front part - the mask by a connecting tube. The filter-absorbing box of the gas mask serves to purify the air inhaled by a person from toxic, radioactive substances and bacterial agents. The box is a cylinder (small or large) equipped (in terms of air flow) with an anti-aerosol filter and an absorber (specially treated activated carbon), sometimes called a charge. All aerosols are retained on the anti-aerosol filter; radioactive dust, fumes and mists of toxic substances and bacterial aerosols. The charge traps vapors and gases of poisonous substances.

At the bottom of the box there is a round hole for inhaled air to enter it; The purified air exits the box through a neck in the box lid.

The front part of the gas mask is designed to bring the air purified in the filter-absorbing box to the respiratory organs, as well as to protect the face and eyes from getting poisonous, radioactive substances and bacterial agents on them. The helmet-mask (mask) is made of rubber; has two spectacle nodes, fairings and a valve box; the mask, in addition, is equipped with elastic bands and a nape for attaching it to the head. Inside the box there is an inhalation valve and two exhalation valves (main and secondary).

Helmets-masks are produced in five (with a membrane box - four), and masks - in three heights. Height is indicated by a number on the chin part of the helmet-mask and mask. The helmet-mask is connected to the filter-absorbing gas mask box by means of a screw pipe attached to the valve box and a screwed neck on the box lid.

A gas mask bag is designed to store and carry a gas mask. It closes with a valve. For the convenience of carrying a gas mask, a shoulder strap (band) is sewn to the bag, the length of which can be adjusted using a mobile buckle, and a waist band (cord).

Used to protect against carbon monoxide Hopcalite cartridge. It must be attached to a gas mask when working in an atmosphere poisoned with carbon monoxide, since the filter-absorbing box of a gas mask does not protect the human body from carbon monoxide. The body of the hopcalite cartridge is metal. There is an external screw neck on the housing cover. for connection with the connecting tube of the gas mask (helmet-mask), and at the bottom - an internal screw neck for connection with the filter-absorbing box of the gas mask. The cartridge is equipped with hopkalitam and a desiccant.

Hopkalite is used to oxidize carbon monoxide with atmospheric oxygen to carbon dioxide. The desiccant is silica gel impregnated with calcium chloride. It absorbs water vapor from the air passing through the hopcalite cartridge, protecting it from moisture. Moistened hopcalite loses its properties. With an increase in its mass due to moisture by 20 g or more, it is impossible to use a gopkalnt cartridge. The mass of the cartridge is indicated on the box. Hopkalite cartridge has protective properties for about 2 hours.

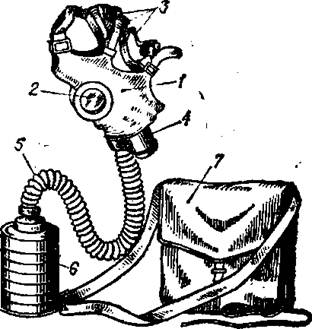

Figure 1. Gas mask GP - 5: a - helmet mask; b - gas mask box; in - a box with films; g - bag.

Figure 2. Gas mask GP - 4u: 1-mask; 2 points; 3-ribbons; 4-valve box; 5-connecting tube; 6-box gas mask; 7-bag.

Insulating gas masks. Insulating gas masks (IP-4, IP-5) are special means of protecting the respiratory organs, eyes, skin, face from all harmful impurities contained in the air. They are used when filtering gas masks do not provide such protection, as well as in conditions of lack of oxygen in the air. The air necessary for breathing is enriched in insulating gas masks with oxygen in a regenerative cartridge equipped with a special substance (sodium peroxide and superoxide). The gas mask consists of: front part, regenerative cartridge, breathing bag, frame and bag.

Respirators and simple respiratory protection. In the civil defense system, the greatest application Has a R-2 respirator(Fig. 3). Respirators are used to protect the respiratory organs from radioactive and ground dust and when operating in a secondary cloud of bacterial agents. Respirators do not protect a person from toxic substances. The P-2 respirator is a filtering half mask equipped with two inhalation valves, one exhalation valve (with a safety screen), a headband consisting of elastic (stretchable) and non-stretchable ribbons, and a nose clip.

The outer part of the half mask is made of porous synthetic material polyurethane, and the inner part is made of a thin air-permeable film, in which the inhalation valves are mounted.

Figure 3. Respirator P - 2: left - general form; on the right - in combat position; 1 half mask, 2 inhalation valve, 3 exhalation valve, 4 elastic bands, 5 non-stretch bands, 6 nose clip.

Between the polyurethane and the film there is a filter made of polymeric materials.

When you inhale, the air passes through the entire surface of the respirator and the filter, is cleaned of dust and enters the respiratory organs through the inhalation valves. When you exhale, the air exits through the exhalation valve.

The R-2 respirator is made in three sizes, corresponding to the dimensions of the GP-4u gas mask (they are indicated on the inner chin part of the half mask on the label enclosed in a plastic bag). Therefore, a respirator is selected in size in the same way as a gas mask GP-4u.

A respirator selected in size must be tried on and checked for tightness of its half-mask to the face. It should also be checked for correctness. To do this, put on a half-mask on the face so that the chin and nose are placed inside it, and press the ends of the nose clip to the nose. To check the fit of the worn half-mask to the face, tightly close the opening of the safety screen of the exhalation valve with the palm of the hand and exhale lightly. If, at the same time, air does not escape along the line of contact of the respirator to the face, but only slightly inflates the mask, the respirator is put on tightly; if the air passes, then it is necessary to press the ends of the nose clip more tightly to the nose. If the tightness is still not ensured, it is necessary to take a smaller respirator. After fitting and checking, the respirator must be placed in a bag, closed with a ring and stored in this form with you.

At the end of the use of a respirator in conditions radioactive contamination it must be deactivated; remove radioactive dust from the outer surface, and wipe the inner surface with a damp swab. Then the respirator is placed in a bag, the bag is closed with a ring and stored in this form.

If a lot of moisture appears during use of the respirator, it is recommended to remove it for 1-2 minutes, remove moisture, wipe the inner surface and put it on again.

Anti-dust fabric mask PTM-1. Like a cotton-gauze bandage, it is intended to protect the human respiratory organs from radioactive dust and during the action of bacterial agents in a secondary cloud. Mostly the population itself makes masks and bandages. The mask and bandage do not protect people from poisonous substances. The air is cleaned by the entire surface of the mask as it passes through the fabric during inhalation. The mask consists of two main parts - the body and the mount (Fig. 4, A). The body is made of four to five layers of fabric. It has viewing holes with glasses inserted into them. On the head, the mask is fastened with a strip of fabric sewn to the side edges of the body. A snug fit of the mask to the head is ensured with the help of an elastic band in the upper seam and ties in the lower seam of the attachment, as well as with the help of a transverse elastic band sewn to the upper corners of the mask body. A mask can be made by every worker, collective farmer, employee, student.

When sewing a mask, they are guided by special instructions. Cut out all its parts, observing the appropriate dimensions. There are seven sizes in total. With a face height of up to 80 mm, a mask of the first size is sewn, with a height of 81 to 90 mm - of the second size, from 91 to 100 mm - of the third (these sizes are intended for children from 8 to 17 years old), from 101 to 110 mm - of the fourth, from 111 to 120 mm - the fifth, from 121 to 130 mm - the sixth and from 131 mm and above - the seventh size (for adults). For the top layer of the mask, it is recommended to use coarse calico, ( Scottish, calico; for the inner layers - cloth, fumes, woolen fabrics and fabrics that do not get dirty when wet.

The body and fasteners of the mask are cut out according to templates cut out of cardboard. The finished mask is carefully checked and tried on. A properly made and sized mask should fit snugly with its edges to the surface of the forehead, temples, cheekbones and chin with a strip of at least 2-3 cm wide, and glasses glasses should be at eye level.

The mask is worn when there is a threat of contamination with radioactive dust. Before putting it on, you need to remove the headgear, take the mask with both hands on the lower edges of the fastening so that the thumbs are turned outward. Attach the lower part of the mask to the chin, and put the mount behind the head, press the mask tightly to the surface of the face, straighten the mounts on the head with the palms of your hands, pull off and tie the ends of the occipital ties, and then put on the headgear.

When leaving the contaminated area, the mask is decontaminated as soon as possible: cleaned (radioactive dust is knocked out), washed in hot water with soap and rinsed thoroughly with a change of water.

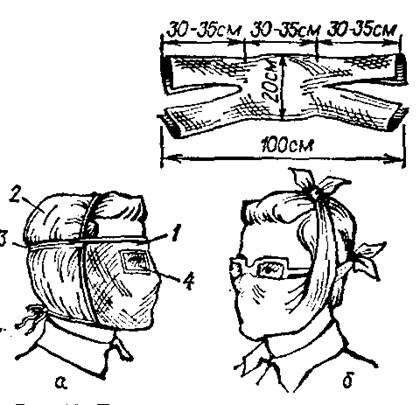

Figure 4. Anti-dust fabric mask (PTM) (a) and cotton-gauze bandage (VMP) (b): 1-corps; 2-fastening; 3-elastic band for attaching the mask; 4 points.

Cotton-gauze bandage (Fig. 4, B). It is produced by its population on its own. This requires a piece of gauze measuring 100 x 50 cm. A layer of cotton wool 1-2 cm thick, 30 cm long, 20 cm wide is applied to the gauze. The gauze is folded on both long sides and applied to the cotton wool. The ends are cut lengthwise at a distance of 30-35 cm so that two pairs of ties are formed. If necessary, cover the mouth and nose with a bandage; the upper ends are tied at the back of the head, and the lower ends at the crown. Lumps of cotton wool are placed in narrow strips on both sides of the nose. Protective eyewear must be worn to protect the eyes.

If there is no respiratory protection, then it is necessary to moisten any rag, handkerchief with water, and in the absence of water - with urine, attach it tightly to the nose and breathe through it. In this case, radioactive dust will linger on a rag.

Gas masks.

Modern gas masks have sufficiently high protective properties and performance indicators that protect the respiratory organs and human eyes from the effects of poisonous (OS) and highly toxic substances (SDN) (vapours, fog, smoke, drop-liquid agents), radioactive substances (RS) located in air, as well as pathogenic microorganisms and toxins in the aerosol state.

According to the principle of protective action, gas masks can be insulating and filtering. The most widely used filtering gas masks (combined arms, civil, children). Their device is based on the principle of cleaning contaminated air in the inner layers of the filter-absorbing box, in which activated carbon (with a catalyst) and an anti-aerosol (anti-smoke) filter are placed. Respiratory protection from carbon monoxide, which is not retained by the protective layers of the filter-absorbing box, is ensured by using a special hopcalite cartridge, which is inserted (screwed) between the connecting tube (front part) of the gas mask and the filter-absorbing box.

Filtering gas masks.

Currently, filtering gas masks GP-5, GP-5M, and GP-7 can be used for the adult population; to protect children - filtering gas masks DP-6M (children's gas mask, type six, small), DP-6 (children's gas mask, type six). PDF-7 (children's filtering gas mask, type seven), PDF-D (children's filtering gas mask, preschool) and PDF-Sh (children's filtering gas mask, school).

In addition, to protect children under the age of 1 year, there is a children's protective camera, type six (KZD-6).

Unstable gas masks include industrial gas masks, especially widely used in chemical plants. The boxes of these gas masks are specialized, the mixture may contain various absorbers or an absorber and an aerosol filter.

Device basics.

The gas mask consists of a front part (mask, helmet-mask), a filter-absorbing box, a spectacle assembly, a valve box, a connecting tube, a gas mask bag.

The filtering-absorbing (gas mask) box is made of tin, has a round or oval shape. To increase the strength of the box, there are transverse protrusions (ridges) on the body. On the cover of the box there is a neck for attaching the box to the front of the gas mask. At the bottom of the box there is a round hole through which the inhaled air enters. During storage, it is closed with a rubber stopper.

To protect the metal from rust, the box is painted on the outside, and covered with black varnish on the inside. Equipped (according to the air flow) with an anti-smoke (anti-aerosol) filter and a coal-catalyst (charge).

The anti-aerosol filter is designed to delay the RH, RW and BS used in the form of smoke, fog or dust aerosols. It is prepared from materials that have a large number of long and tortuous channels (from cellulose or asbestos).

The anti-aerosol filter of modern gas masks best of all retains large aerosols - more than 0.3 microns in size and small aerosols - less than 0.1 microns; worst of all, it retains aerosols, ranging in size from 0.1 to 0.3 microns. Large particles with a large mass and high inertia on the convolutions ("turns") of the filter channel fly out of the air jet and, "hitting" the channel surface, are delayed. Extremely small particles, having a pronounced Brownian motion and "hitting" at the same time on the surface of the channel, are also delayed. Particles ranging in size from 0.1 to 0.3 microns, on the one hand, are so small that, having no inertia, they do not fly out of the air stream, on the other hand, they are so large that they do not have a pronounced Brownian motion. Therefore, particles of this size, following the flow of the air jet, penetrate the anti-aerosol filter and give a certain percentage of breakthrough. Good modern filters have a breakthrough factor of 0.0001 - 0.0000001%.

The mixture (universal absorber) of the gas mask box is designed to delay poisonous substances that are in a state of molecular dispersion (in the form of gas or vapor). The charge is based on activated carbon, which is one of the most porous bodies in nature. The pore surface of one gram of such coal reaches 800-900 square meters. meters. Therefore, 1 g of coal can absorb up to 0.5 g of organic matter.

When the OM passes through activated carbon, a number of physicochemical processes occur, united by a common name - sorption. Special cases of sorption are processes called adsorption, absorption, chemisorption and capillary condensation.

During adsorption, the sorbed substances (sorbtive) are compacted on the surface of the sorbent (the gas is compacted on the surface of the coal). If in this case the formation of new chemical compounds occurs, the process is defined as chemisorption.

During absorption, the sorbed substance penetrates (diffuses) into the sorbent mass. In some cases, the vaporous adsorbed substance liquefies under the influence of capillary forces of the sorbent. This process is called capillary condensation.

Adsorption and capillary condensation are of the greatest practical importance in relation to activated carbon.

Activated carbon adsorbs the gases of substances that have a high molecular weight and a high boiling point best of all. Thus, it well adsorbs vapors of mustard gas, lewisite, soman, chloropicrin, weaker - chlorine, diphosgene and extremely weakly - hydrocyanic acid, as well as other acidic agents and their decomposition products. Coal does not retain smoky, foggy agents and carbon monoxide at all.

To enhance the chemisorption of activated carbon, increase its protective power with respect to phosgene (diphosgene) and other acidic agents (and their decomposition products), basic chemical additives are applied to large pores of coal.

For amplification protective properties gas mask from cyanide compounds, a method based on the complexation of hydrocyanic acid with salts of heavy metals was used. To do this, activated carbon is impregnated not only with alkalis, but also with metal salts, such as copper, etc. The interaction of alkalis and metal salts with hydrocyanic acid leads to the formation of strong complex salts.

Excessive introduction of chemical impregnations can reduce the activity of coal due to the exclusion of micropores from its operation. Therefore, the optimal weight of impregnations should not exceed 2% by weight of coal.

The front part of the gas mask serves to conduct purified air to the respiratory organs and to protect the eyes and face from toxic and radioactive substances, as well as from pathogenic microbes and toxins. It consists of a helmet-mask or a mask with goggles and devices for protecting glasses from fogging, a valve box and a connecting tube. The front parts have a different size. The smallest growth is zero, the largest is the fourth. Height is indicated on the chin part of the mask. The mask is made of elastic rubber. The arched corrugations and bulges for the ears are designed to provide a more even pressure of the helmet on the blood vessels of the head, which reduces pain.

Flat goggles made of ordinary glass are hermetically inserted into the helmet-mask (mask). Together with the glass, a spring ring and a rubber gasket are mounted in the spectacle cuff.

The valve box is used to distribute the flow of inhaled and exhaled air. It has one inhalation valve and two exhalation valves.

The inhalation valve is a round rubber plate with a hole in the center. When you inhale, the valve rises and passes the inhaled air under the helmet-mask, and when you exhale, it presses against the saddle and blocks the way for the exhaled air into the filter-absorbing box.

The exhalation valve consists of a saddle and a rubber petal, interconnected by four paws. The petal is solid. When inhaling, it is pressed against the saddle, as a result of which the outside air cannot get under the helmet-mask. It is made of rubber and has transverse folds in the form of corrugations, which increase its flexibility and do not allow it to shrink when bent. The upper end of the tube ends with a metal pipe, on which a nut is put on for connection with the neck of the valve box.

The lower end of the tube ends with a metal nipple. A union nut is put on it, with the help of which the tube is attached to the neck of the filter-absorbing box.

Not all gas masks have a connecting tube, but only industrial and some children's ones. Civilian gas masks GP-5 and GP-7 do not have it. They have a filter-absorbing box directly attached to the valve box.

Gas mask accessories include: non-fogging films, "pencil" against fogging glasses and insulating cuffs.

The non-fogging film is a circle of celluloid, on one side of which a layer of gelatin is applied, which has a high hygroscopicity. By absorbing moisture, it swells, as a result of which a homogeneous water-gelatin layer is formed on the celluloid, providing good visibility. Anti-fog film prevents glasses from freezing in winter at temperatures down to -10 C.

"Pencil" anti-fogging glasses is used in the absence of anti-fogging films. A thin transparent layer is applied to the inside of the glasses. When water vapor condenses, not individual droplets form on it, but a continuous transparent film of soap solution. In the absence of a "pencil" you can use ordinary soap.

The insulating cuffs are made of rubber, they are fitted with spectacle glasses. The cuffs are worn over the goggles of the helmet-mask. It turns out double glasses with an air cushion between the glasses. This prevents the windows from freezing. They are used at temperatures below -10C, with the simultaneous use of non-fogging films.

When passing through the filter-absorbing box, harmful, poisonous and toxic substances are completely retained for some time. However, over time, their traces may appear in the air leaving the box - a slip, which characterizes the exhaustion of the protective capabilities of the gas mask. The time from the beginning of its use to the moment the substance slips through is called the protective power of the gas mask and is expressed in hours and minutes.

In a modern gas mask, breathing resistance at an air flow rate of 30 l / min is 18-21 mm. water. Art. The protective power for pairs of persistent agents is several tens of hours.

The effect of a gas mask on the body.

When using a gas mask, three factors act on the human body: breathing resistance, harmful space and pressure from the front of the gas mask.

Breathing resistance is measured by the difference in air pressure in the atmosphere and in the space under the mask and is expressed in millimeters of water column. Breathing resistance depends on the density of the filter, the thickness of the layer and the size of the activated carbon grains, as well as the speed of the inhaled air, which in turn is determined by the amount of air consumed per minute. Its amount depends on the nature and intensity of physical activity. At rest, a person consumes 9 liters per minute, while standing in a room 12 liters, while walking at a speed of 4 km / h - 25 liters, while running at a speed of 12 km / h - 64 liters. Accordingly, the resistance of a gas mask to breathing when a person is at rest is about 15 mm of water. Art., and when running increases to 250 mm of water. Art.

The harmful space in a gas mask is the internal volume of all its cavities, where exhaled air with a high content of carbon dioxide and water vapor is retained. When you breathe in again, this air is mixed with the purified air coming from the filter-absorbing box.

The impact of the front part of the gas mask is reduced to the mechanical pressure of the mask on the face and head, which causes pain, a decrease in the sharpness and size of the field of view, difficulty in speech, decreased hearing, and irritation of the skin of the face. These phenomena are reduced or eliminated by the correct selection of a mask and training in a gas mask.

Civilian gas masks.

To protect the population, filtering gas masks GP-5 (GP-5M) and GP-7 are used.

The GP-5 gas mask is designed to protect a person from getting into the respiratory organs, eyes and face of radioactive, toxic, potent toxic substances and bacterial agents.

It consists of a filter-absorbing box and a front part (helmet-mask). The GP-5M gas mask kit includes a helmet-mask with a membrane box for an intercom.

To select the required height of the helmet-mask (0,1,2,3,4), it is necessary to measure the head along a closed line passing through the crown, cheeks and chin. With a measurement value of up to 63 cm, zero height is taken, from 63.5 to 65.5 cm - the first, from 66 to 68 - the second, from 68.5 to 70.5 cm - the third, from 71 cm and more - the fourth.

Gas mask GP-7 is one of the latest and most advanced models. It consists of a filter-absorbing box GP-7K, a front part, non-fogging films (6 pcs), insulating cuffs (2 pcs), a protective knitted cover and a bag. Its weight in a set without a bag is 900g. Inspiratory breathing resistance at a constant airflow rate of 30 l/min. is not more than 16 mm water column, at 250 l / min. - no more than 200 mm. water.st.

The GP-7 gas mask is available in two versions that differ in the design of the front part: GP-7 and GP-7V. The gas mask GP-7 is equipped with the front part of the MGP with an intercom and without a device for drinking. The gas mask GP-7V is equipped with the front part of the MGP-V with an intercom and a device for drinking from a flask, which makes it possible to receive water in a contaminated atmosphere.

The front part of the gas mask is made in three heights. It consists of a mask of a three-dimensional type with an "independent" obturator of the spectacle assembly, an intercom (membrane), inhalation and exhalation valve assemblies, a fairing, a headband and pressure rings for fixing non-fogging films.

GP-7 in comparison with GP-5 has a number of significant advantages in terms of operational and physiological parameters. Reducing the resistance of the filter-absorbing box makes breathing easier. An independent obturator provides a more reliable seal and at the same time reduces the pressure of the face of the gas mask on the head. Reducing breathing resistance, pressure on the head allows you to increase the time spent in a gas mask. It can be used by people over 60 years of age, as well as patients with pulmonary and cardiovascular diseases.

The selection of the front part of the required standard size GP-7 is carried out on the basis of the results of measuring the horizontal and vertical girth of the head. The horizontal girth is determined by measuring the head along a closed line passing in front along the superciliary arches, from the side by 2-3 cm. above the edge of the auricle and behind through the most protruding point of the head. Vertical girth is determined by measuring the head along a closed line passing through the crown, cheeks and chin. Measurements are rounded to the nearest 5mm. According to the sum of two measurements, the required standard size is set - the height of the mask and the position (number) of the stops of the headband straps in which they are fixed. The position of the straps of the headband is set when fitting the gas mask.

Rules for fitting the front parts of the gas mask GP-7

Children's gas masks.

There are five types of children's gas masks. For kids younger age(starting from 1.5 years) - gas mask DP-6M (children's gas mask, type six, small), for the older - DP-6 (children's gas mask, type 6).

More common PDF-7 (children's filtering gas mask, type 7). Designed for both toddlers and older children. It differs from DP-6 in that it is equipped with a filter-absorbing box from an adult gas mask GP-5. As the front part, MD-1 masks of five heights are used.

Gas masks PDF-D and PDF-Sh (gas mask for children, filtering, preschool or school) have a single filter-absorbing box GP-5 and differ only in front parts. PDF-D is equipped with MD-Z (children's mask, third type) of four heights - 1,2,3,4. The masks have a headband in the form of a thin rubber plate with five ribbons, equipped with ledges with numbers. Their fitting begins with the following position of the numbers of the ribbons at the buckles: frontal - 6, temporal - 8, cervical - 9. The connecting tube at the mask of the 1st growth is attached to the side of the valve box. PDF-D is intended for children from 1.5 to 7 years old. PDF-Sh is intended for children from 7 to 17 years old. As the front part, MD-Z masks of two heights are used, namely, 3 and 4.

Today, the most advanced model is the PDF-2D children's gas mask for preschool children and PDF-2Sh - for school age. The set of these gas masks includes: a filter-absorbing box GP-7K, the front part of MD-4, a box with non-fogging films and a bag. PDF-2D is completed with the front parts of the 1st and 2nd, PDF-2Sh - 2nd and 3rd growth. Weight of the set: preschool - no more than 750 g, school - no more than 850 g. The filter-absorbing box is similar in design to the GP-5 box, but has a reduced inhalation resistance.

For children of preschool and primary school age, gas masks are worn by adults. This is done as follows: the child is placed with his back to himself, the headdress is removed, the hair is collected from the forehead and temples, the front part is taken by the temporal and buccal straps and applied to the face so that the chin is located in the lower recess of the obturator, moving the hands up and back from the face the child's headband is pulled over the head, the skew of the front part, the turn-ups of the obturator and straps are eliminated, the cheek buckles are fastened. Warranty ribbons are tied for preschool children. They put on a headdress.

In order to remove the PDF-2D or PDF-2Sh gas mask, the cheek straps are first unraveled, then the front part is taken by the exhalation valve assembly, pulled down and removed by moving the hand forward and up.

New children's gas masks have a number of advantages. They have reduced breathing resistance during inhalation, the pressure of the front part of the gas mask on the head is reduced. All this allows you to increase the time spent by children in protective equipment. The design of the front part is such that it became possible to reduce the number of growths to three and greatly facilitate the selection of gas masks.

At present, new types of combined-arms filtering gas masks have been developed. These are gas masks - PMG and PBF.

PMG - a small-sized gas mask, consisting of a helmet-mask, a small-sized gas mask box, directly connected to the valve box.

PBF - boxless filtering gas mask, consisting of a helmet-mask and 2 cheek elements.

In these gas masks, harmful space and breathing resistance are significantly reduced. They are able to provide respiratory protection for 3 hours.

Additional ammo.

Gas masks GP-5 and GP-7 as well as children's gas masks PDF-7, PDF-D, PDF-Sh, PDF-2D, PDF-2Sh protect against such SDYAV as chlorine, hydrogen sulfide, sulfur dioxide, hydrochloric acid, hydrocyanic acid, tetraethyl lead , ethyl mercaptan, nitrobenzene, phenol, furfural, phosgene, chloroethane.

In order to expand the capabilities of gas masks to protect against SDYAV, additional cartridges (DPG-1 and DPG-Z) have been introduced for them.

DPG-Z, complete with a gas mask, protects against ammonia, chlorine, dimethylamine, nirobenzene, hydrogen sulfide, carbon disulfide, hydrocyanic acid, tetraethyl lead, phenol, phosgene, furfural, hydrogen fluoride, cyanogen chloride and ethyl mercaptan. DPG-1 also protects against nitrogen dioxide, methyl chloride, carbon monoxide and ethylene oxide.

The set of additional cartridges DPG-1 or DPG-Z includes a connecting tube and an insert. The cartridge has a cylindrical shape and looks like a filter-absorbing box GP-5, GP-7.

Inside the DPG-1 cartridge there are two layers of charge, a special absorber and hopcalite, in

DPG-Z has only one absorber layer.

Air flow resistance no more than 10 mm. water. Art. at a flow rate of 30 l/min. The weight of the DPG-1 cartridge is not more than 500 g, DPG-3 - 350 g.

The time of protective action according to SDYAV for civil gas masks GP-5, GP-5M with additional cartridges DPG-1 and DPG-Z, at an air flow rate of 30 l / min, relative humidity of 75% and ambient temperature from 30 degrees C to + 40 degrees is from 0.5 hours to 5 hours.

Hopcalite cartridge. Additional cartridge to gas masks to protect against carbon monoxide. The design resembles DPG-1 or DPG-Z.

Equipped with a dehumidifier and, in fact, hopkalite. The desiccant is silica gel impregnated with calcium chloride. Designed to absorb air water vapor in order to protect hopcalite from moisture, which loses its properties when moistened.

Gopkalit - a mixture of manganese dioxide with copper oxide, acts as a catalyst in the oxidation of carbon monoxide at the expense of atmospheric oxygen to non-toxic carbon dioxide.

On the hopcalite cartridge, its initial weight is indicated. With an increase in weight due to moisture absorption by 20 g or more against the original, the cartridge cannot be used. The time of the protective action of the cartridge at a relative humidity of 80% is about two hours. At a temperature close to zero, its protective effect is reduced, and at -

15 C and below almost stops. The hopcalite cartridge is used when the content of carbon monoxide in the atmosphere is not more than 1%. Cartridge weight 750-8OOg.

Isolating gas masks.

Isolating gas masks (type IP-4, IP-5, IP-46) or oxygen isolation devices (KIP-5, KIP-7, KIP-8) completely isolate the human respiratory organs from the outside air. Breathing occurs due to the release of oxygen from a regenerative cartridge or supplied from an oxygen cylinder. These gas masks and devices are used for work if the following are observed in the air: high concentrations of RH (SDYAV), when a dangerous "breakthrough" of them is possible and the filter gas mask does not provide adequate protection; lack of oxygen content; high concentrations of carbon monoxide.

According to the principle of providing oxygen, insulating gas masks and devices are divided into two groups: with chemically bound and with compressed oxygen. Gas masks of the first group include IP-4, IP-5, IP-46, IP-46m; gas masks of the second group include insulating devices KIP-5, KIP-7, KIP-8.

Device basics.

The insulating gas mask consists of: a front part, a regenerative cartridge with a trigger, a breathing bag with an overpressure valve, a frame and a bag. The gas mask kit includes: a spare starting briquette in a case, a box with an ampoule, a box with anti-fogging films, a combination key.

The duration of the starting briquette is up to 2 minutes. The briquette is stored in a special case.

The regenerative cartridge consists of a body, two caps with necks and a trigger. It is designed to absorb carbon dioxide and water vapor from exhaled air and release oxygen for breathing. The regenerative cartridge is filled with grains of sodium peroxide with the addition of calcium hydroxide, which enter into chemical reactions with the release of oxygen.

All these reactions are exothermic, accompanied by the release of heat, therefore, as the cartridge is used, it heats up from top to bottom. The regenerative cartridge is connected by means of nipples to a corrugated tube and a breathing bag.

The starting device serves to actuate the regenerative cartridge and consists of a starting briquette with an oxygen-containing substance, an ampoule with sulfuric acid, a rubber diaphragm and a union nut with a safety cap. Before using the gas mask, the briquette is placed in the socket of the regenerative cartridge, above it is an ampoule with acid and closed with a union nut. When the ampoule is crushed, a chemical reaction occurs, during which up to 12 liters of oxygen is released and the upper part of the cartridge is heated.

The breathing bag with a capacity of 4 liters is placed in the frame and has an overpressure valve that automatically opens when the pressure in the bag is 25-30 mm of water. Art., releasing excess oxygen from the bag so that there is no difficulty in exhaling.

The time of the protective action of an insulating gas mask with one regenerative cartridge:

- in a calm state up to 5 hours.

Under water up to 40 min.

The selection of a helmet of an insulating gas mask is carried out by size, which is determined by measuring the head along a closed line passing through the crown and chin. Only 4 sizes.

The gas mask must fit close to the head and prevent oxygen from escaping to the outside.

When assembling and preparing a gas mask for use, you must:

Attach the regenerative cartridge to the counterlung;

Prepare the starting device for action;

Attach the front part to the regenerative cartridge;

Remove a glass ampoule with acid from the tin box and insert it with a metal cap inside the suction cup of the rubber diaphragm, remove the safety pin and crush the ampoule by pressing the diaphragm with your hand.

The effect of an insulating gas mask on the body.

The process of air regeneration in an insulating gas mask is accompanied by the release of a significant amount of heat. In this regard, the temperature of the inhaled gas mixture is usually 37-40 degrees and can be even higher at high outdoor temperatures or during intense physical activity, which can lead to discomfort.

Breathing resistance in IP-46 at rest does not exceed 25-30 mm of water. Art., when performing physical work, due to an increase in pulmonary ventilation, it increases and can be 100-150 mm of water. Art., and when running - 200-250 mm of water. Art. A sharp increase in the resistance of the gas mask to breathing can lead to a relative decrease in heart rate, an increase in the minimum arterial pressure with a decrease in pulse pressure and a decrease in stroke and minute volume of the heart. With a sharp transition from a state of rest to intense physical work, the rate of oxygen supply to the respiratory bag of the gas mask lags behind the rate of its consumption by the body, which can cause a limitation in the volume of respiratory movements of the chest and a sharp difficulty in breathing. In this case, there is a feeling of a lack of a gas mixture on inspiration. Therefore, under conditions of being in an insulating gas mask, the intensity of physical activity should be increased gradually.

When operating an insulating gas mask, the following safety measures must be observed:

Timely check the serviceability of the assembled gas mask during storage. If a gas mask leak is detected, the regenerative cartridge and the starting briquette must be replaced with new ones (after the malfunction has been eliminated);

Before carrying out work in a room or inside a tank with a toxic substance, if possible, ventilate the room, degas the tank;

The number of persons simultaneously working in insulating gas masks in one room must be at least two, and continuous communication must be maintained with them;

In smoky rooms, cisterns, etc. each person working in an insulating gas mask must be tied with a cable, the other end of which is located at a specially designated duty or backup number located outside a smoky room (tanks, etc.);

Do not start work in a gas mask if you are not firmly convinced that the starting briquette worked at startup;

If the front part of the gas mask is removed during a break in work, the regenerative cartridge must be replaced with a new one;

Timely finish work in an insulating gas mask or replace the regenerative cartridge;

Do not allow water and organic substances to get on the starting briquette and the regenerative cartridge when preparing the gas mask for use;

When dousing the helmet with oxidizing agents, replace the gas mask;

Reuse of gas masks that have been doused with aggressive liquids should be allowed only after neutralization and a thorough check of their condition.

Respirators.

Respirators are used as respiratory protection against radioactive dust, harmful gases and aerosols.

Respirators are divided into two types. The first - in which the half mask and the filter element simultaneously serve as the front part of the respirator. The second - cleans the inhaled air in the filter cartridges attached to the half mask.

Purification of inhaled air from vapor-gaseous impurities is carried out due to physical and chemical processes (adsorption, chemisorption and catalysis), and from aerosol impurities - by filtering through fibrous materials.

According to their purpose, they are divided into anti-dust, anti-gas and gas-dust protection. The former protect the respiratory organs from various types of aerosols, the latter from harmful vapors and gases, and the latter from gases, vapors and aerosols with their simultaneous presence in the air.

Fine-fiber filter materials are used as filters in anti-dust respirators.

Depending on the service life, respirators can be disposable (ShB-1, "Lepestok", "Kama", UK-2, R-2), which after working out are unsuitable for further use. Reusable respirators provide filter replacement. These include: anti-gas filtering respirator RPG-67, RPG-67A, RPG-67 B; respirator filtering gas-dustproof RU-60M.

It is forbidden to use these respirators to protect against highly toxic substances such as hydrocyanic acid, arsenic, phosphorus, hydrogen cyanide, tetraethyl lead, low molecular weight carbohydrates (methane, ethane), as well as from substances that, in a vapor-gas state, can enter the body through intact skin.

The R-2D respirator is a modification for children, has smaller dimensions, provides continuous use for 4 hours.

The simplest means of respiratory protection.

The simplest means of respiratory protection can be used by the population as respirators. They are simple in design and are therefore recommended as mass media protection produced by the population itself. Such means include anti-dust fabric masks PTM and cotton-gauze bandages. Each person should have them at the place of residence and work.

The PTM mask consists of two main parts - the body and the mount. The body is made of 2-4 layers of fabric. Viewing holes are cut out in it with glasses or a transparent film inserted into them. On the head, the mask is fastened with a strip of fabric sewn to the side edges of the body. A snug fit of the mask to the head is ensured with the help of an elastic band in the upper seam and ties in the lower fastening seam, as well as a transverse elastic band sewn to the upper corners of the mask body. The air is cleaned by the entire surface of the mask as it passes through the fabric during inhalation.

Cotton-gauze dressings are made from a piece of gauze 100x50 cm in size. A layer of cotton wool 30x20 cm in size and 2 cm thick is laid on the middle of a piece of gauze, the free edges of the gauze are folded onto cotton wool, and the ends are cut in the middle for ties. The lower ends are tied at the crown, and the upper ends at the back of the head. The cotton-gauze bandage should tightly cover the mouth and nose. It is suitable for single use. In the absence of these funds, towels, scarves, scarves, etc. are used. Anti-dust goggles can be used to protect the eyes from RH.

Introduction

At work with harmful working conditions, as well as at work performed in special temperature conditions or associated with pollution, workers are given free overalls, safety shoes and other means personal protection. Personal Protective Equipment (PPE) is used to protect workers. Means of individual and collective defense workers - technical means used to prevent or reduce the impact on workers of harmful or hazardous production factors, as well as to protect against pollution (Article 209 Labor Code RF). In accordance with GOST 12.4.011-89 Protective equipment for workers, depending on the nature of their use, is divided into two categories: collective protective equipment and personal protective equipment. Personal protective equipment is called equipment designed to ensure the safety of one worker. Personal protective equipment includes: 1. Isolating suits: pneumosuits, waterproofing suits, space suits. 2. Means of respiratory protection: gas masks, respirators, self-rescuers, air helmets, air masks, air jackets. 3. Special protective clothing: sheepskin coats, coats; short coat, short fur coats; capes; raincoats, semi-cloaks; bathrobes; suits; jackets, shirts; trousers, shorts; overalls, semi-overalls; vests; dresses, sundresses; blouses, skirts; aprons; shoulder pads. 4. Foot protection: boots; boots with an elongated shaft; boots with a shortened shaft; half boots; boots; low shoes; shoes; shoe covers; galoshes; bots; slippers (sandals); high fur boots, dudes; shields, boots, knee pads, footcloths.

5. Hand protection: gloves; gloves; semi-gloves; fingertips; handhelds; wristlets; sleeves, elbow pads. 6. Head protection: protective helmets; helmets, balaclavas; caps, berets, hats, caps, scarves, mosquito nets. 7. Eye protection: goggles. 8. Face protection equipment: protective face shields. 9. Hearing protection: anti-noise helmets; anti-noise inserts; anti-noise headphones. 10. Fall protection and other safety equipment: safety belts, ropes; manual grips, manipulators; knee pads, elbow pads, shoulder pads. 11. Dermatological protective means: protective; skin cleaners; reparative agents. 12. Means of protection are complex. Overalls, special footwear and other personal protective equipment issued to employees are considered the property of the organization and are subject to mandatory return: upon dismissal, when transferred to another job, at the end of the wearing period in exchange for a new one, unless a different procedure is established in the organization. Personal protective equipment is issued for a certain period, which is calculated from the date of their issuance to the employee. The administration is obliged to replace or repair overalls and special footwear that have become unusable before the expiration of the established wear period for reasons beyond the control of the employee. Failure to use personal protective equipment can lead to accidents.

Chapter 1. Individual means of respiratory protection.

1.1 Civilian gas masks.

Filtering gas masks are designed to protect a person from getting into the respiratory system, eyes and face of radioactive dust, toxic substances and biological agents.

The principle of protective action is based on preliminary filtration of inhaled air from harmful impurities. Before use, the gas mask must be checked for serviceability and tightness. At present, the GP-7 filtering gas mask is used in the civil defense system for the adult population. It reliably protects against toxic substances and many SDYAV, radioactive dust and bacterial agents. The selection of the front part of the required type of size GP-7 is carried out on the basis of measuring the horizontal and vertical girth of the head with a soft centimeter tape. Then, according to special tables, a gas mask face mask is selected. It reliably protects against toxic substances and many SDYAV, radioactive dust and bacterial agents. Fairly light, little hindrance to movement. At long work makes it difficult to breathe, the filter box is clogged, a slip is possible. Limits the field of view.

1.2 Industrial gas masks

Industrial gas masks reliably protect the respiratory organs, eyes, face from damage. It must be remembered that they are designed to protect against specific toxic substances. Therefore, they have a strict orientation (selectivity), which allows to increase their protective power.

It is forbidden to use such gas masks with a lack of oxygen in the air. For example, when working in tanks, cisterns, wells and other isolated rooms. They are used only where the air contains at least 18% oxygen, the total volume fraction of vapor and gaseous harmful impurities does not exceed 0.5% (hydrogen phosphite - no more than 0.2%, arsenic hydrogen - 0.3%).

It is not allowed to use industrial gas masks to protect against low-boiling, poorly absorbed organic substances, such as methane, ethylene, acetylene. It is not recommended to work in such gas masks if the composition of gases and vapors of harmful substances is unknown.

The time of the protective action of industrial gas masks from potent toxic substances depends on the brand of the filter box, the type of SDYAV and its concentration. In the process of use, the protective power of gas masks decreases. For example, if even a slight smell of harmful substances appears, boxes of grades A, B, E, KD, BKF cannot be used. It is necessary to immediately exit the bled zone and replace the box with a new one.

It should be remembered that the protective power of CO and M gas masks for carbon monoxide is reduced if the charge is moistened with water vapor. Therefore, the safety service after each use must disconnect the boxes, and close the necks on the bottom and lid with caps with rubber gaskets.

1.3 Hose gas masks

They are used when cleaning tanks and other containers from oil products, during welding works in closed and semi-closed volumes (pits, wells).

1. PSh-1 designed to protect the respiratory system from any harmful gas, steam, smoke and dust in any concentration in an atmosphere with a lack of oxygen.

2. PSh-2 designed for the same conditions as PSh-1. However, in it, the air under the helmet-mask is forced by a fan, and therefore there is no resistance to breathing. The fresh air supply unit has electric and manual drives. The electric drive allows to supply up to 50 l/min of fresh air under the helmet-mask.

1.4 Gas masks

Isolating gas masks (IP) are special tool protection of respiratory organs, eyes, face skin from any harmful impurities in the air, regardless of their properties and concentration, are used in emergency situations, if it is impossible to use filtering gas masks. For instance:

1. in the presence in the air of such toxic substances or harmful impurities that are poorly or not at all retained by filtering gas masks.

2. at very high concentrations of toxic substances in the air, when filtering gas masks can give a very fast breakthrough.

3. with oxygen starvation, the oxygen concentration in the air is less than 16%

4. when working underwater at a depth of less than 7 meters.

Complete isolation of the respiratory organs from the environment. The indicators depend on the supply of oxygen and the nature of the work performed. IP is divided into:

1. gas masks based on chemically bound oxygen

2. gas masks based on compressed air or oxygen

1.5 Cotton-gauze bandage

Protects the main part of the face from the chin to the eyes, made of cotton and gauze (or only cotton). A cotton-gauze bandage can protect against chlorine, for this it is impregnated with a 2% solution of baking soda, and impregnated with a 5% solution of citric or acetic acid protects against ammonia. It is single use, after use it is burned. Usually, a cotton-gauze bandage is used with glasses.

1.6 Respirators and chemical respirators

Respirators are a lightweight means of protecting the respiratory system from harmful gases, vapors, aerosols and dust. Respirators have become widespread. In mines, in mines, in chemically harmful and dusty enterprises when working with fertilizers and pesticides in agriculture.

Purification of inhaled air from vapor-gaseous impurities is carried out due to physical and chemical processes (adsorption, chemisorption, catalysis), and from aerosol impurities - by filtering through fibrous materials.

Respirators are divided into two types:

1. The first is respirators, in which the half mask and the filter element simultaneously serve as the front part.

2. The second purifies the inhaled air in the filter cartridges attached to the half mask.

By appointment, respirators are divided into:

1. Anti-dust protect respiratory organs from aerosols various kinds. Fine-fiber filter materials are used as filters in anti-dust respirators. The most widely used polymeric filter materials such as FP (Petryanov filter), due to their high elasticity, mechanical strength, high dust capacity, and, most importantly, due to high filtering properties.

2. Gas masks - from harmful vapors and gases.

3. Gas and dust protection - from gases, vapors and aerosols with their simultaneous presence in the air.

- Irrational expressions (expressions with roots) and their transformation

- Retelling of the work "The Tale of How One Man Feeded Two Generals" by Saltykov-Shchedrin M

- Vasily Ermolaevich Bugor was an Arctic navigator and one of the pioneers of Siberia

- Arena isomers. The structure of arene molecules. Stabilization of the σ-complex. It is carried out by splitting off a proton from the σ-complex with the help of a base. In this case, due to the two electrons of the breaking covalent bond C - H, the closed π-system is restored.

- What equipment to put on borscht level 8

- M56 Scorpion — Tier VII American tank destroyer

- Chemical properties of zinc and its compounds

- Levels of life organization of living systems

- How to cook forshmak from herring in Odessa, in a Jewish way and in a new way Forshmak from herring a classic Jewish recipe

- American pumpkin pie

- Curd cake without baking with strawberries

- Salad "mushrooms under the snow" Salad "Mushrooms under the snow" - a step by step recipe with a photo

- Chocolate shortbread cookies with lard

- Homemade zucchini caviar in a slow cooker for the winter: a simple and very tasty Zucchini caviar a quick recipe in a slow cooker

- Meat pies from yeast dough Meat filling for pies how to cook

- Zucchini Pancakes How to make Zucchini Pancakes

- Rusks in the oven, temperature

- Gingerbread recipes for perfect gingerbread recipes with light icing

- How to cook zucchini caviar in the traditional way and in a slow cooker?

- Spells to call on a date Spells to call on a date