Protective equipment. Insulating rods.

Good time of the day, dear friends!

Today I will dwell on the insulating rods in more detail, because questions still arise.

So insulating rods are electrical protective equipment.

Insulating rods belong to the main protective equipment both in installations up to 1000V and in installations above 1000V.

PURPOSE AND DESIGN.

Insulating rods are designed for operational work (operations with disconnectors, changing fuses, installing arrester parts, etc.), measurements (checking insulation on power lines and substations), for applying portable grounding, as well as for freeing the victim from electric current.

General technical requirements for insulating operational rods and portable grounding rods are given in the state standard GOST 20494. Insulating operational rods and portable grounding rods. General technical conditions.

The rods should consist of three main parts: working, insulating and a handle.

The rods can be composed of several links. To connect the links to each other, parts made of metal or insulating material can be used. The use of a telescopic structure is allowed, while reliable fixation of the links in the places of their connections must be ensured.

The rod handle can be integral with the insulating part or be a separate link.

The insulating part of the rods should be made of electrical insulating materials that do not absorb moisture, with stable dielectric and mechanical properties.

The surfaces of the insulating parts must be smooth, free from cracks, delamination or scratches.

The use of paper-bakelite tubes for the manufacture of insulating parts is not allowed.

Operational rods can have replaceable heads (working parts) to perform various operations. In this case, their reliable fastening must be ensured.

The design of portable grounding rods should ensure their reliable detachable or permanent connection with grounding clamps, installation of these clamps on live parts of electrical installations and their subsequent fastening, as well as removal from live parts.

Composite rods of portable grounding for electrical installations with a voltage of 110 kV and above, as well as for imposing portable grounding on overhead line wires without lifting onto supports, can contain metal live links in the presence of an insulating part with a handle.

For intermediate supports of overhead power lines with a voltage of 500-1150 kV, the grounding structure may contain an insulating flexible element instead of a rod, which should be made, as a rule, of synthetic materials (polypropylene, nylon, etc.).

The design and weight of the operating, measuring rods and to release the victim from an electric current for a voltage of up to 330 kV should ensure the ability to work with them by one person, and the same rods for a voltage of 500 kV and above can be designed for two people using a supporting device. In this case, the greatest effort on one hand (supporting at the restrictive ring) should not exceed 160 N.

The design of portable grounding rods for laying on overhead lines with a person lifting to a support or from telescopic towers and in switchgears with a voltage of up to 330 kV should ensure the ability to work with them by one person, and portable groundings for electrical installations with a voltage of 500 kV and above, as well as for applying grounding to Overhead line wires without lifting a person onto a support (from the ground) can be designed for two people using a supporting device. The greatest effort on one hand in these cases is regulated by the technical conditions.

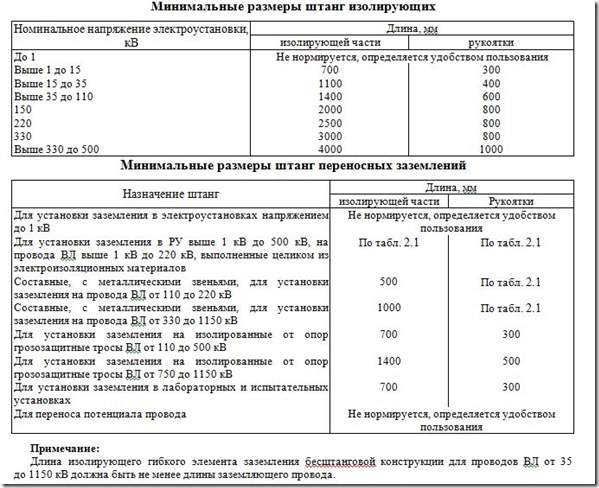

The main dimensions of the rods must be at least as indicated in the following tables:

Performance Tests

During operation, mechanical tests of the rods are not carried out.

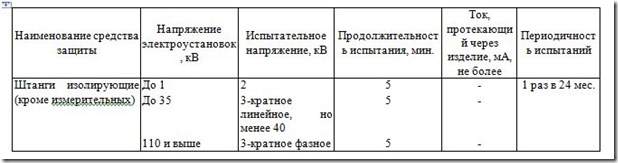

High voltage electrical tests of insulating parts of operating and measuring rods, as well as rods used in testing laboratories for high voltage supply, are carried out in accordance with the following requirements:

Acceptance, periodic and type tests are carried out at the manufacturer according to the standardsand the methodologies outlined in the relevant standards or specifications.

In operation, protective equipment is subjected to regular and extraordinary operational tests (after a fall, repair, replacement of any parts, if there are signs of a malfunction).

The tests are carried out according to approved methods (instructions).

Mechanical tests are carried out before electrical ones.

All testing of protective equipment must be carried out by specially trained and certified personnel.

Before testing, each protective equipment must be carefully examined in order to check the presence of the manufacturer's marking, number, completeness, absence of mechanical damage, the condition of the insulating surfaces (for insulating protective equipment). If the protective equipment does not meet the requirements

INSTRUCTIONSAPPLICATION AND TESTINGMEANS OF PROTECTION USEDIN ELECTRICAL INSTALLATIONS (SO 153-34.03.603-2003)

The tests are not carried out until the identified deficiencies are eliminated.

Electrical tests should be carried out with alternating current of power frequency, as a rule, at a temperature of plus (25 ± 15) ° С.

Electrical tests of insulating rods should begin with checking the dielectric strength of the insulation.

The rate of voltage rise up to 1/3 of the test voltage can be arbitrary (a voltage equal to the specified one can be applied by pushing), further increase in voltage should be smooth and fast, but allowing reading the readings of the measuring device at a voltage of more than 3/4 of the test voltage. After reaching the normalized value and holding at this value for the normalized time, the voltage must be smoothly and quickly reduced to zero or to a value not exceeding 1/3 of the test voltage, after which the voltage is switched off.

The test voltage is applied to the insulating part of the protective equipment. In the absence of a suitable voltage source for testing the entire insulating rods, it is allowed to test them in parts. In this case, the insulating part is divided into sections, to which a part of the normalized total test voltage is applied, proportional to the length of the section and increased by 20%.

The main insulating electrical protective equipment intended for electrical installations with voltages above 1 to 35 kV inclusive are tested with a voltage equal to 3 times the linear voltage, but not lower than 40 kV, and those intended for electrical installations with a voltage of 110 kV and above are tested with a voltage equal to 3 times the phase voltage.

The duration of the full test voltage is typically 1 min. for insulating protective equipment up to 1000 V and for insulation made of elastic materials and porcelain and 5 min. - for insulation from layered dielectrics.

For specific protective equipment and working parts, the duration of application of the test voltage is given in the Appendices. 5 and7 .

Breakdown, overlap and discharges along the surface are determined by disconnecting the test setup during the test, according to the readings of measuring instruments and visually.

Electrical protective equipment made of solid materials should be checked by feeling immediately after the test for the absence of local heating due to dielectric losses.

In the event of a breakdown, overlap or discharges along the surface, an increase in the current through the product above the normalized value, the presence of local heating, the protective device is rejected.

In this case, a voltage is applied between the working part and a temporary electrode applied at the restricting ring from the side of the insulating part.

Tests are also carried out on the heads of the measuring rods for the control of insulators in electrical installations with a voltage of 35-500 kV.

Portable grounding rods with metal links for overhead lines are tested according to the method of p. 2.2.13 Instructions ...

Tests of the remaining rods of portable grounding are not carried out.

The insulating flexible earthing element of the rodless structure is tested in parts. A portion of the total test voltage proportional to the length and increased by 20% is applied to each section 1 m long. Simultaneous testing of all sections of an insulating flexible element wound into a coil is allowed so that the length of a semicircle is 1 m.

The norms and frequency of electrical tests of rods and insulating flexible grounding elements of rodless construction are as follows:

.

Terms of use

Before starting work with rods with a removable working part, it is necessary to make sure that there is no "jamming" of the threaded connection of the working and insulating parts by screwing and unscrewing them once.

The measuring rods are not grounded during operation, unless the principle of the rod requires grounding.

When working with an insulating rod, climb or descend from a structure or telescopic tower without the rod.

In electrical installations with voltages above 1000 V, insulating rods should be used with dielectric gloves.

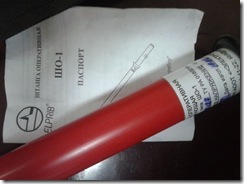

Operational bar SHO-1 up to 1000 V looks like this:

Operational rod SHO-10 up to 10kV

Operational universal bar SHOW-10:

When the handle rotates, the clamp of the working part is compressed or unclenched, which is used to replace the safety inserts.

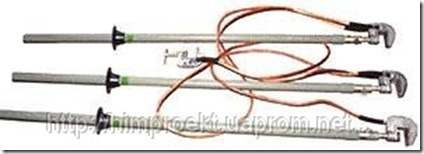

The portable grounding rod looks like this:

There may be not three, but one rod, which is alternately connected to each clamp.

How do you know whether the bar is suitable for use or not?

According to the stamp applied to the bar in the area of the handle after the next electrical tests of the following form:

№ _______

Suitable up to _____ kV

Date of next test "____" __________________ 20___

_________________________________________________________________________

(laboratory name)

Where the serial or stock number of the bar is indicated, the upper voltage limit at which the bar can be operated, the date of the next test (if the date is overdue, then the bar's operation is unacceptable), the name of the ETL that carried out the test of the bar.

As for the storage of the rods, they should be stored in a specially designated place, suspended, positioned perpendicular to the ground, avoiding the creation of mechanical stresses in them in order to avoid deformation or breakage.

That's all for me.

- Rules for the use of electrical protective equipment when carrying out work in electrical installations

- How to sew fleece mittens

- Protective equipment in electrical installations

- Computer glasses: which is better to choose

- How to wash clothes with Thinsulate insulation

- Training in electrical safety, labor protection, ecology, electrical safety, fire-technical minimum, first aid to victims of the courses

- Protective equipment in electrical installations up to and above 1000 Volts

- What is fleece fabric, where is it used and how to care for it

- Personal protective equipment

- What is this fabric?

- Thinsulate

- Unusual New Year's performances for the whole family "system" of brothers zapashny

- Formation and development of human society

- Styles in music: list, description, examples Genres of song performance

- Unusual New Year's performances for the whole family

- Secrets of the origin of Georgian, Armenian and Azerbaijani surnames Who has a surname ending in yang

- Leonardo di ser piero da vinci artworks

- Then Gia Eradze's Burlesque show is for you!

- Before his death, Murat Nasyrov was euphoric and dreamed of performing at the Eurovision Song Contest Murat Nasyrov to which group he sang

- Taisiya Povaliy: biography, personal life, children, musical career, photo