Rules for the use of electrical protective equipment when carrying out work in electrical installations

Electrical protective insulating means are designed to ensure the safety of service personnel when performing work in existing electrical installations. Depending on the purpose and type, an electrical protective device can provide both complete protection of a person from voltage and act as an additional protection.

Electrical installations pose a danger in terms of the possibility of electric shock and thermal effects of an electric arc. Every year there are a number of accidents in electrical installations, most of which occur due to non-compliance by workers with labor protection requirements, in particular, improper use of protective equipment during work. Therefore, it is very important to know and be able to correctly use electrical protective equipment when performing work on electrical equipment.

Consider the basic rules for the use of various protective equipment that are used in electrical installations.

Here are the basic rules for the use of electrical protective equipment that apply to all protective equipment.

If it is necessary to work with one or another means of protection, it is necessary, first of all, to check its suitability for use. First, attention is paid to the appearance of the insulating agent. It should be free of dirt, damage to the case, including paintwork.

Each protective insulating device must be periodically tested - a check for suitability for use in electrical installations. Therefore, before applying a protective agent, it is necessary to check its validity period - the date of the next test on a stamp of the established sample.

If the electrical protective equipment is dirty, damaged to the case, or if it has expired the period of periodic testing, then such protective equipment must not be used, as this could result in electric shock to a person. Such a protective device must be withdrawn from service for troubleshooting, testing.

The electrical protective equipment that is planned to be used provides its insulating properties only if they are dry. This feature must be taken into account if it is necessary to work in open switchgears, avoiding the use of protective equipment that has gotten wet (drizzle, rain, frost, snow). If it is necessary to perform work in conditions of moisture ingress, electrical protective equipment specially designed for this purpose must be used.

In addition, the protective sealants must be kept clean. This is especially true for dielectric gloves, shoes and other protective equipment, which quickly become unusable if various aggressive liquids and lubricants get on their rubber surface.

Electrical protective equipment above 1000 V with gripping handles are structurally equipped with limit rings. When performing work, it is necessary to take protective equipment by the handles no further than this restricting ring. This is due to the fact that there is a permissible safe distance to live parts and the protective device is designed in such a way that its insulating part (the part that separates the working part from the handle) is long enough to provide protection against electric shock.

It should also be noted that each electrical protective device is designed to operate at a specific voltage. The voltage class is indicated on the body of the protective device, but this value may differ from the voltage value from which the protective device is really capable of protecting a person. Therefore, when testing a protective device, indicate the voltage value up to which this device can be used.

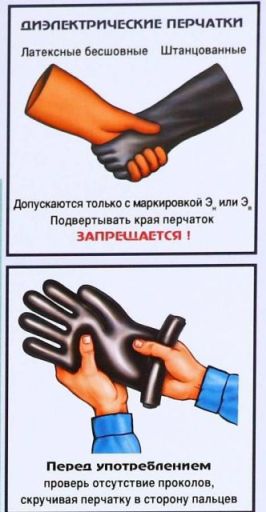

Dielectric gloves serve as the main means of protection against electric shock in electrical installations up to 1000 V and as additional protection in electrical installations with voltages above 1000 V.

Only absolutely dry dielectric gloves are allowed to be used. If the room where they are stored has a high level of humidity, then before working with gloves, they should be dried indoors at room temperature.

Before using gloves, in addition to external examination, checking the date of the next test, it is necessary to check them for punctures. To do this, you need to start twisting them from the edge towards the fingers. In this case, the glove inflates a little and by pressing it is possible to detect possible punctures through which air will escape.

Insulating pliers are used to replace fuses. When replacing fuses with a voltage class higher than 1000 V, in addition to an insulating clamp, dielectric gloves and protective goggles or masks must be used as an additional means of protection. In electrical installations up to 1000 V, you can use only pliers or dielectric gloves together with glasses or masks to replace fuses.

Replacement of fuses should be carried out with preliminary disconnection of the load. The exception is the fuses for those sections of the electrical network in which there are no switching devices, through which the load can be removed.

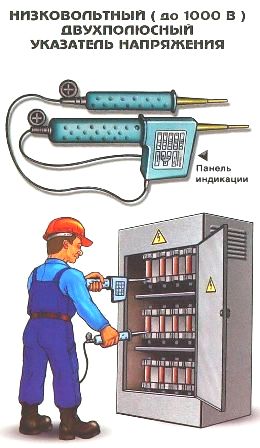

Voltage indicators

Voltage indicators are used in electrical installations to check the presence or absence of voltage on live parts.

If the voltage indicator is equipped with a voltage class switch, then before using it, you must make sure that the selected mode is correct.

If it is necessary to check the absence of voltage on live parts, it is necessary to first check the operability of the used voltage indicator. The indicator is tested for operability on those live parts of the switchgear that are under operating voltage. Also, to test the performance of voltage indicators above 1000 V, special devices can be used to test indicators.

Checking the presence of voltage or checking the operation of the indicator must be performed carefully to avoid overlap between phases or one of the phases to the equipment frame or other grounded metal structures of the switchgear.

When checking the absence of voltage, one should take into account the peculiarities of the operation of individual types of voltage indicators. If the voltage indicator is of pulse type, then it works with a certain delay. Before using this or that type of voltage indicator, it is necessary to familiarize yourself with the instructions for its operation, which indicate the characteristic features concerning this or that voltage indicator.

When working on electrical installations above 1000 V, voltage alarms can be used as an additional safety measure.

Voltage alarms are attached to a protective helmet of an employee or on the wrist and are triggered when a person approaches live parts that are energized. Voltage alarms should not be used as a primary means of checking that there is no voltage. For this purpose, only voltage indicators must be used.

If the voltage signaling device does not have a built-in health control, then before starting work it must be checked in the prescribed manner in compliance with safety measures.

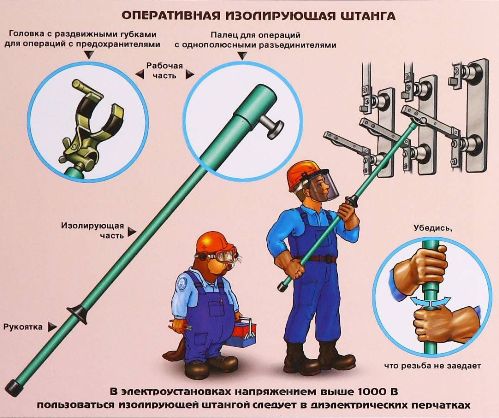

Insulating rods

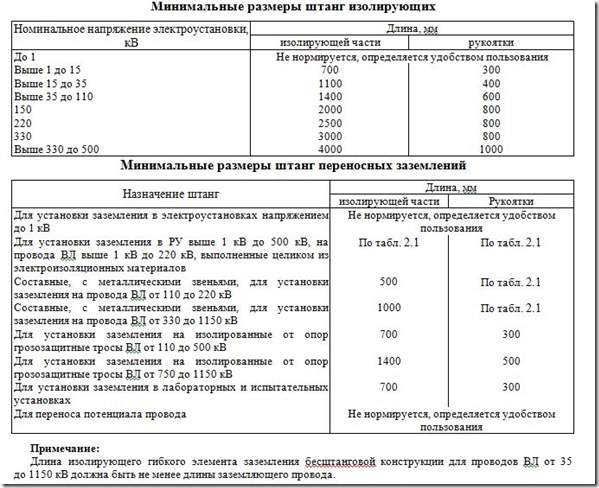

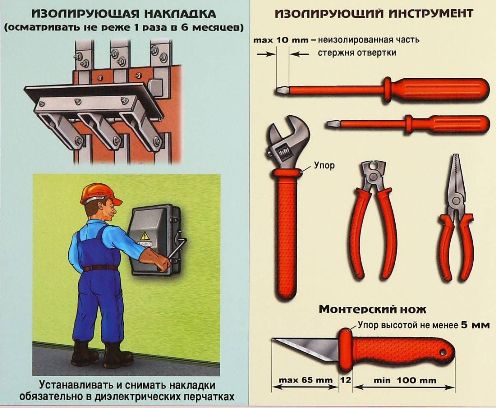

Insulating rods, depending on the design, can be designed for: installing portable protective earthing, performing operations with switching devices, installing insulating linings, replacing fuses, taking measurements.

Before using this or that bar, you need to make sure that it can actually perform this or that operation. It is forbidden to perform the work with the barbell for which it is not provided.

Individual types of insulating rods must be grounded without fail before use. Such rods cannot be used without grounding.

Insulating rods and voltage indicators for voltages above 1000 V can consist of several parts, connected by a threaded connection. Before using such electrical protective equipment, it is necessary to check the reliability of their threaded connections, in order to avoid incidents during work.

Dielectric shoes - boots, galoshes

Dielectric boots and galoshes are designed to protect a person from electric shock to a person in the area of spreading of earth fault currents - from the so-called step voltage. Dielectric footwear also serves as a protective device when it is necessary to ensure the isolation of a person from the ground (indoor floor surface), in this case, the footwear acts as an alternative to a rubber dielectric carpet and an insulating stand.

Dielectric shoes must be carefully inspected for punctures, visible damage before use. When using dielectric shoes, you must move carefully, avoiding punctures, which is especially important if you need to move in open areas. Damage to the surface of dielectric shoes can result in an electric shock to a person, for example, in the area of step voltage.

Before using a boat or galoshes, it is imperative to check the stamp with the date of the next test, which should also indicate the voltage at which these protective equipment is able to isolate a person from the effects of current.

Insulating tool

Hand tools with insulating handles (screwdrivers, pliers, side cutters, pliers, wrenches, etc.) serve as the main electrical protective equipment when working in electrical installations up to 1000 V without removing the voltage.

In electrical installations above 1000 V, hand tools with insulating handles do not provide safety when performing work, therefore, if it is necessary to perform work on, it must be disconnected from all sides from which voltage can be applied, ground, install fences and take other measures to avoid approaching person at an unacceptable distance to live equipment.

When working in electrical installations up to 1000 V without removing the voltage, in addition to tools with insulating handles, it is necessary to ensure the isolation of a person from the ground (floor surface), using dielectric carpets, insulating supports or dielectric shoes. Depending on the nature of the work performed, it is necessary to use additional protective maxi or goggles.

Before using a hand tool, it is necessary to inspect it for damage to the insulating part - kinks, cracks, burrs. Hand tools with insulating handles, like other protective equipment, are periodically tested in an electrical laboratory, therefore, before using it, it is also necessary to check the timing of the next test.

Portable protective earthing

To protect a person from accidentally applied voltage, as well as the effect of induced voltage of some power lines, equipment is grounded - electrical connection of live parts with grounded equipment elements, directly to the grounding loop. Grounding is carried out using stationary grounding knives and portable protective grounding.

Stationary earthing knives are a structural element of disconnectors, individual types of cells, chambers with equipment. Portable grounding is a protective device that should be given special attention. This protective device is installed manually or using built-in or removable rods for installing earthing.

Installation of grounding is carried out directly on live parts, which must first be disconnected and make sure that there is no voltage on them.

A lot of accidents happen because before installing grounding, the absence of voltage is not checked on all three phases. The fact is that the switching devices, by means of which the disconnection of a section of the equipment (creating a visible gap) is ensured, can be disconnected incompletely, that is, one of the phases can remain energized, which subsequently, when installing grounding, leads to electric shock to a person.

As mentioned above, before checking the absence of voltage, it is necessary to check the operability of the voltage indicator.

If we are talking about installing portable grounding on equipment above 1000 V, then it is imperative to use special rods, while also using dielectric gloves. To ensure safety, the installation of portable groundings must be carried out by two people; removal is allowed to be done alone.

If this or that section of the power grid is grounded at the same time with stationary grounding and portable, then it is necessary to turn on the stationary grounding first so that the installation of portable groundings is safe.

Before using portable groundings, it is necessary to inspect them for the integrity of the conductors, clamps, fasteners of the conductors to them. Insignificant, no more than 5%, damage to the cores is allowed.

In order for the portable grounding to fully provide protective functions, it is necessary to correctly select its type, cross-section in accordance with the voltage class and operating currents of the electrical installation section in which the grounding is planned to be installed.

In addition to the protective equipment listed above, it is necessary to use personal protective equipment - overalls, shoes, a protective helmet. Depending on local conditions and the nature of the work performed, it is necessary to use protective equipment against the effects of various negative factors.

For example, in an area with a high level of influence of an electromagnetic field, it is necessary to use special protective clothing sets. When carrying out operational switching, use a special protective suit and shield that provides protection against possible effects of an electric arc.

In conclusion, it should be noted that in addition to the knowledge and ability to correctly apply protective equipment when performing work, it is very important to perform the work correctly, deliberately, carefully in order to avoid mistakes and create dangerous situations. Protective equipment cannot provide absolute protection of a person from possible dangerous situations.

An incorrectly selected switching device, incorrect operation and other errors can lead to accidents. Therefore, the issue of safety when carrying out work in electrical installations must be approached comprehensively, taking into account all possible nuances.

- Rules for the use of electrical protective equipment when carrying out work in electrical installations

- How to sew fleece mittens

- Protective equipment in electrical installations

- Computer glasses: which is better to choose

- How to wash clothes with Thinsulate insulation

- Training in electrical safety, labor protection, ecology, electrical safety, fire-technical minimum, first aid to victims of the courses

- Protective equipment in electrical installations up to and above 1000 Volts

- What is fleece fabric, where is it used and how to care for it

- Personal protective equipment

- What is this fabric?

- Thinsulate

- Characteristics of the mop from Pushkin's "captain's daughter"

- Characteristics of the main characters of the work Fathers and Sons, Turgenev

- Ivan Turgenev: biography, life and creativity

- Brief biography of Ivan Sergeevich Turgenev And with Turgenev his

- "Fathers and Sons": Heroes of Turgenev's Immortal Work. Fathers and Sons of Turgenev Characteristics of the Heroes

- Characteristics of the main characters based on the novel I

- The image of Rodion Raskolnikov based on the novel Crime and Punishment (Dostoevsky F

- "Dubrovsky" by Pushkin: plot and history of creation

- The image of eugene onegin by chapters