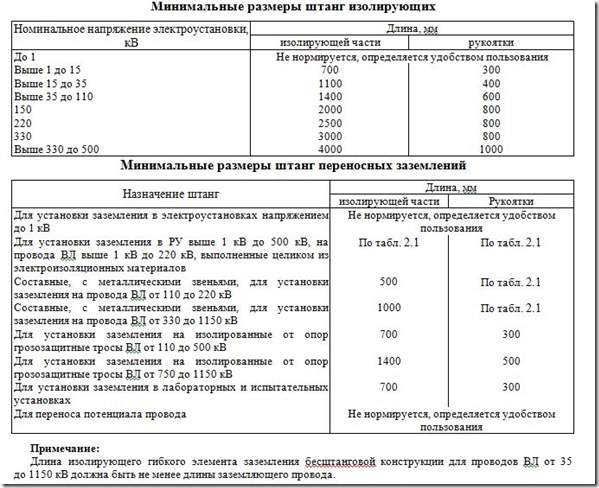

Terms of testing of protective equipment used in electrical installations

In the process of working on electrical installations, it is imperative to use protective equipment (ES) - items that prevent a person from falling under the negative effect of electricity. It is important to understand correctly which ES should be used, what they are for, and how to maintain them in good condition, where special attention should be paid to checking and replacing them.

Protective equipment against electric current

APs protect workers from the following electrical factors:

- electric shock - electrical protection means;

- the negative impact of the impact of a powerful electromagnetic field - protection means in electrical installations, where the voltage reaches 330 kV and more;

- the need for personal protective equipment - PPE.

As can be seen from the table, funds are basic (OZS) and additional (DZS).

List of basic and additional means of electrical protection

| The main insulating electrical funds | Additional insulating electrical protection funds |

||

|---|---|---|---|

| above 1000 V: | In electrical installations with voltage up to 1000V: | In electrical installations with voltage above 1000 V: | In electric tans nap- disguise up to 1000V: |

| voltage indicators | voltage indicators | insulating caps and linings | insulating caps, coverings and overlays |

| insulating pliers | insulating pliers | dielectric rugs and insulating stands | dielectric carpets and insulating coasters |

| insulating rods of all kinds | insulating rods of all kinds | dielectric gloves and boots | dielectric galoshes |

| devices and devices for ensuring the safety of work during measurements and tests in electrical installations (voltage indicators for checking the phase coincidence, electrical clamps, devices for cable puncture, etc.) | electrical pliers, dielectric gloves, hand insulating tool | transfer and potential equalization rods | stairs attached, stepladders insulating glass teak |

| special protective equipment, insulating devices and devices for work under voltage in electrical installations with a voltage of 110 kV and above (except for rods for transfer and potential equalization) | dielectric gloves | ladders, insulating fiberglass step ladders | |

Protection against electric current

OZS are needed in the process of servicing electrical installations to create a reliable barrier when touching live current-carrying elements. A distinctive feature of DZS is that they do not independently protect against electric shock, but should be used in conjunction with OZS, the reliability of which they increase, protecting against arc, step voltage or electric shock from conductive elements. In the figure above, in the table, OZS and DZS are in separate lists.

Special requirements are imposed on the properties of the materials used for the manufacture of OZS. They have a stable dielectric characteristic. They include porcelain, bakelite, getinax, rubber, ebonite, etc.

The quality of dielectric gloves and other products depends on the type of rubber used. Requirements for high electrical resistance and sufficient elasticity are imposed on it. All products have certain operating periods, because over time, the quality of rubber deteriorates under the influence of the external environment, oil products, aggressive substances and from damage. Therefore, tests are carried out for the AP, and a certain frequency is observed here, in accordance with the established standards.

The products are manufactured for two different conditions of use in electrical installations:

- Up to 1000 V - OZS. Not applicable for higher voltages.

- Above 1000 V - used as an OZS together with the main OZS or when controlling switches for voltages over 1000 V. These dielectric gloves are allowed to be used as OZS on electrical installations less than 1000 V.

Gloves are put on completely so that the sleeves can be closed on top of the sleeves of the garment. For this, their width should be sufficient. Wrapping of their edges is not allowed.

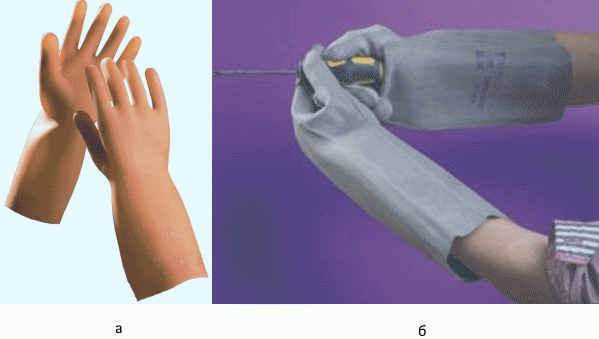

Gloves are made with or without a seam, from special rubber (Fig. Below). The fact that they are ZS is indicated by the marking Ev or En. The sizes used must be large enough to be able to fit underneath knitted seals.

Dielectric gloves: a - seamless; b - single-suture

Checking products before work includes an external examination for defects, cuts, tears, dirt and excessive moisture. All these factors significantly reduce the dielectric properties of the ZP. Gloves are checked for tightness by rolling in the direction from the bell to the fingers.

To protect the used dielectric gloves from external influences, ordinary work gloves are worn on top.

During use, gloves are periodically washed with soda, soap and other detergents, after which they must be dried.

Electronic glove test

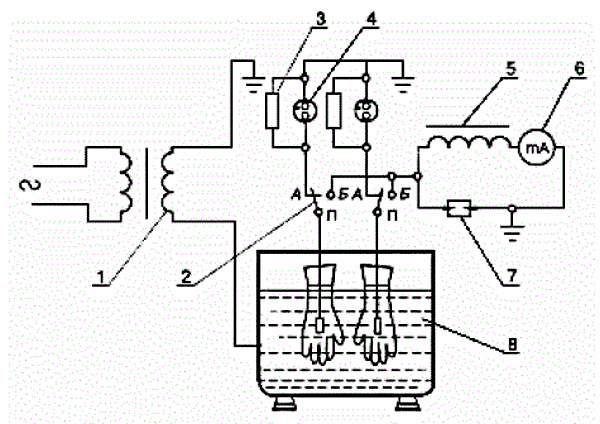

Products are tested in an aqueous environment (Figure below). To do this, water is poured into them with an indentation of about 50 mm from the top, and then immersed in a bath so that the edges remain dry. Voltage is applied to the metal surface of the bath (8) and to the electrode placed in the glove and the current is monitored. If several products are tested, the current is monitored in each of them by switching a milliammeter.

In case of breakdown or when the current through the glove is higher than normal, it is rejected.

Power is supplied through a high-voltage transformer (1). An additional autotransformer can be connected in front of it to control the value of the test voltage.

Diagram of a dielectric glove testing device: 1 - high-voltage transformer; 2 - contacts of switches; 3 - shunt; 4, 7 - arresters; 5 - inductive load; 6 - current device; 8 - capacity

The readings in each product are determined by a milliammeter (6) connected by contacts (2). In this case, the arresters (4) are designed to protect the switched circuits. If the tested glove is punctured, the choke (5) limits the current and protects the circuit with the measuring device from overload.

The table below shows the established standards for the frequency of testing dielectric gloves and other OZS.

Table of parameters for testing the ZS in electrical installations

| Name for- protective means | Voltage electric installation new, kV | Test voltage, K | Duration, min. | Periodicity trials |

|---|---|---|---|---|

| Insulating operational rods | 10 | 40 | 5 | 1 time in 2 years |

| Voltage indicators above 1000 V | Up to 10, above 10, up to 20 | 40 60 | 5 5 | Once a year |

| Voltage indicators up to 1000 V | up to 0.5 | 1 | 1 | _-_ |

| Voltage indicators for phasing | to 10 | 40 | 5 | |

| Cable piercing device | to 10 | 40 | 5 | _-_ |

| Insulating pads - hard | up to 0.5 up to 10 | 1 20 | 5 5 | 1 time in 2 years |

| - flexible | up to 0.5 | 1 | 1 | >> |

| Insulating caps for conductors off cable | to 10 | 20 | 1 | Once a year |

| Flexible insulating pads for live work | up to 1 | 6 | 1 | |

| all stresses | 6 | 1 | 1 time in 6 months. |

Insulating rods

The device consists of three parts: insulating, working and handle. The device is used on or near current-carrying cells. Working elements can be clamps, tips and other designs, depending on the purpose. The universal head is removable to perform various operations. It securely fixes removable devices. The bar becomes a control device after the voltage indicator is attached to it. The number of links used on the insulating part may vary. Telescopic devices are convenient, but solid structures are also used. The norms of the weight load on the hand are normalized and selected so that one or two people can work.

Using rods, they check the quality of insulation, replace fuses, install various parts, carry out operations with disconnectors, measure electrical parameters, apply grounding, etc.

A barbell can be used to release a person who has been injured by an electric shock.

Devices of various types of booms and their requirements are standardized.

In fig. a shows a bar with a clamp and all components of the device are marked.

![]()

Rods used in electrical installations: a - operational; b - portable grounding

Portable earthing contains clamps for connection with live parts or wires (Fig. B). They can be removable or one-piece.

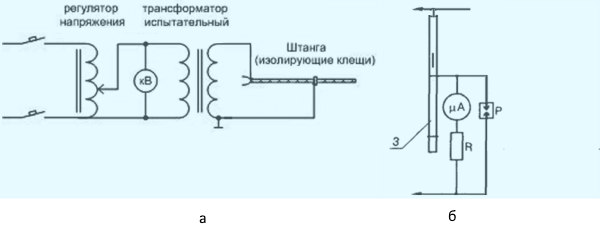

The rods are tested with high voltages applied to their insulating parts. The parameters are shown in the table above. A voltage is applied between the work piece and a removable electrode, which is temporarily attached near the stop between the handle and the insulating part (Fig. A).

Boom performance test diagram

The voltage value is regulated by an autotransformer installed at the device input (voltage regulator). The passing current is checked with a milliammeter protected from overload by an arrester (P) (Fig. B).

Insulating pliers

With the help of insulating pliers, they replace fuses, remove linings, fences and perform other similar work. They are made entirely of non-conductive material (up to 1000 V) or with metal sponges. Their mass allows one electrician to work.

Electric strength tests are carried out similarly to rods. The parameters are shown in the table above.

Instead of insulating pliers, a rod can be used, if a suitable working element is selected.

Electrical pliers are used to measure parameters in circuits up to 1 kV. They contain a secondary winding connected to the instrument. The primary is a high-voltage bus or wire. The working part is a detachable magnetic circuit with a winding and a device.

Voltage indicators

The devices are used to check the voltage in electrical installations, as well as the phasing of high-voltage equipment. The technical requirements for them are set out in GOSTs. As indicators, gas-discharge or LED lamps are used, which are ignited by a capacitive current passing through them. Pointers can be non-contact or with an electrode for direct contact with a bus or wire. Indication can be light, sound or combined. In this case, the signals must be clear and recognizable.

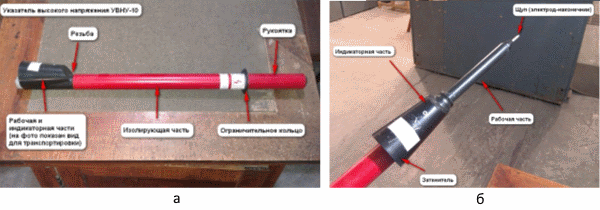

Figure (a) below shows an assembled UVNU-10 high voltage indicator. To create an operational state, it is necessary to unscrew the thread, turn the working part by 180 0 and screw it in again (Fig. B).

Voltage indicator UVNU-10

The tests are carried out on an insulated area and check the indication voltage. The frequency is regulated by the established standards (once a year). The insulated part is checked in the same way as the rods.

The light comes on when the voltage reaches 25% of the nominal.

To test the LED lamp, voltage is applied only to the working part.

Before work, the UVV is checked by touching the current-carrying parts with the working element for 5 seconds. For U> 1000 V), dielectric gloves are required for the device.

Portable grounding

Devices are needed to protect people working on live parts of electrical installations after they are disconnected from voltage induced or supplied by mistake. Constructive designs can be rod or rodless.

Test methods do not differ from insulating rods.

If there is no rod on the ground, the insulating flexible grounding element is checked in parts. You can test it in one go, reeling in the bay.

Dielectric galoshes and boots

Dielectric shoes are an additional means of protection to the OZS, as well as protection against step voltage in electrical installations or on overhead power lines.

Galoshes and boots should be worn on top of regular shoes. Outwardly, they do not differ from her in a very spectacular form, but the main thing here is safety.

Dielectric footwear for work on electrical installations

Before using the products, it is necessary to inspect for the absence of defects: hard inclusions, delamination, ruptures, etc.

Electrical tests of footwear are carried out using the same technology as with dielectric gloves. The norms for filling galoshes and bot with water are respectively 2 cm and 5 cm from the top edge.

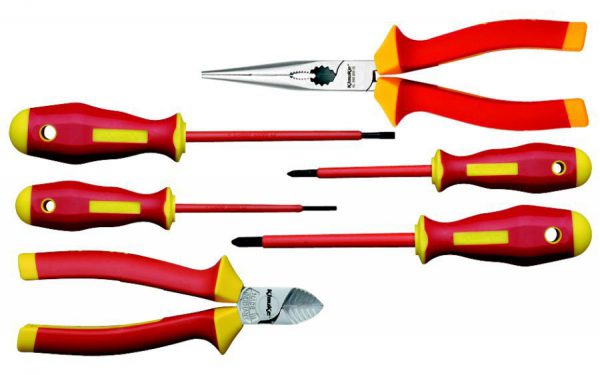

Hand tool

A hand-held insulating tool (RII) is used as an OZS on electrical installations up to 1 kV. It is done of two types:

- metal with full or partial electrical insulation (Figure below);

- completely made of electrically insulating material or with metal inserts.

Insulated Coated Hand Tools

The insulating coating of the metal must be strong enough, resistant to moisture and oil products. Handles of pliers, nippers, etc. are equipped with stops that prevent the hand from touching metal parts during operation.

The instrument should be inspected before each use. The protective layer must be free from defects that reduce its strength and insulating properties.

The hand tool is inspected every six months by a designated worker who records the survey data.

The tool is tested at a voltage of 2 kV with a time delay of 1 min, and the frequency should not be less than once a year.

Terms of use of SZ

- Personnel in electrical installations, provided with the required protective accessories, must receive appropriate training and be able to handle them to ensure safety.

- ZS are marked with the designation of the manufacturer, type of product, date of production, a stamp on electrical tests is required.

- Objects and on-site teams are equipped with inventory stations, as required by the norms and operating conditions. APs are also issued to employees individually. Their distribution is recorded in the lists, which are approved by the head of the electrical facilities. They indicate the storage locations of the AP.

- Unsuitable protective equipment or past service life are subject to withdrawal with a note in the log book. The entry must conform to a specific form.

- APs must be properly operated by workers. They are obliged to monitor the serviceability of the inventory and control the timing of the verification.

Expired APs are strictly prohibited to apply! ZS can only be used for the purposes specified in the instructions. It is especially necessary to monitor the correspondence between the voltages of the facilities and electrical installations.

- OZS can only be used outdoors in dry weather. In case of high humidity, only special ZS can be used.

- Where there is a restriction ring, it is allowed to hold the ЗС during operation only by the handle, up to the limiter.

Checking the status of the AP

- All operated ZS, with the exception of some DZS, are numbered, which is done with paint, embossing on parts or by attaching tags.

- There is a periodicity of inspection (once every six months, and the grounding rods - once every three months) of the state of the AP by the appointed contractor, who must record the data of the verification inspection in writing.

- New gas stations that have entered into service are tested (if standards have been established for this) and stamps are put on the products, establishing the terms of application for the prescribed period. If the result is negative, the stamp is crossed out with paint.

- The results of the checks are recorded in the logs, and separate protocols are drawn up at the AP of third-party organizations.

It is possible to store and move the AP only if they are reliably protected from damage, dirt and moisture. It is forbidden to store them together with instruments. Also, various aggressive substances and oil products are not allowed to enter the gas station.

When transported by mobile teams, protective equipment is in covers, boxes or bags.

ZS test rules

- The frequency of tests of the AP is always maintained, but extraordinary ones are additionally carried out (after repair, when replacing faulty parts, after a shock or fall, if there is a suspicion of a malfunction).

- The check of protective equipment can be carried out only if there is no damage, the insulation is in normal condition, if there is a factory marking, a number, complete completeness. The surface of the insulation must be free of visible defects. Structurally, the devices are made so that they can be easily cleaned or to prevent the ingress of dust and moisture inside. The remarks must be eliminated, otherwise the ES will not be admitted to the electric strength test.

- When checking the insulation, the voltage to 1/3 of the nominal voltage can be raised quickly, then smoothly. After reaching the norm and holding the time interval, the voltage decreases by 1/3 of the test voltage or completely, and then turns off. There are norms for the current passing through the insulation for each material.

- The breakdown is determined visually or according to instrument data. Then the product is rejected.

- ES after shutdown of the installation are checked for overheating.

Video about SZ

Personnel protection equipment and their standardization are described in this video.

For the safety of workers at electrical installations, APs are used, over time they lose their properties. Therefore, there is a specified frequency of regular and extraordinary checks of the AP, so that if the characteristics deteriorate, they can be removed in time and replaced with new ones. When the correct organization of the use and verification of protective equipment is carried out, they provide the necessary electrical safety of work.

- Rules for the use of electrical protective equipment when carrying out work in electrical installations

- How to sew fleece mittens

- Protective equipment in electrical installations

- Computer glasses: which is better to choose

- How to wash clothes with Thinsulate insulation

- Training in electrical safety, labor protection, ecology, electrical safety, fire-technical minimum, first aid to victims of the courses

- Protective equipment in electrical installations up to and above 1000 Volts

- What is fleece fabric, where is it used and how to care for it

- Personal protective equipment

- What is this fabric?

- Thinsulate

- The shameful past of Yulia Efremenkova!

- Version: the director of Uralskiye dumplings died after learning that they wanted to fire him For which the director of the Ural dumplings was killed

- Painting by numbers on canvas and cardboard: an overview of manufacturers, practical tips for beginners

- Do-it-yourself modular paintings - an example of self-execution Do-it-yourself paintings from photowall-paper

- Put a crumpled newspaper in your shoes

- How to put or change strings on a guitar

- The Basics of Composition in Photography Sense of Composition in Photography

- The basics of drawing a portrait

- How to draw on the theme of Good and Evil in stages?