General information about fibers. Textile fibers and threads. Classification. Artificial fibers

Textile fibers can be natural or chemical.

Natural fibers are those that occur naturally. Fibers are composed of substances related to high molecular weight compounds - polymers. Of the naturally occurring substances, polymers, for example, include cellulose - the main part of plant fibers, keratin and fibroin - the main protein substances that make up wool and silk.

Viscose, copper and acetate fibers

When chemical fibers these types are produced commercially for textile purposes. The technological process is a chemical transformation of a natural polymer, the last phase of which is the spinning of an alkaline viscose solution into an acid bath, where the fiber is formed and its structure is formed. The subsequent process of cable production is its cutting into a staple, washing, drying, packaging and dispatching. Matting of fibers is carried out by diffusion scattering light of titanium oxide.

The most important natural textile fiber is cotton. At ginning plants, raw cotton (cotton seeds covered with cotton fiber) is cleaned of plant impurities (parts of bolls, leaves, etc.) that have gotten during the collection of cotton, and then the fibers are separated from the seeds on special machines - fiber separators. Then the fiber is pressed into bales and sent to a spinning mill.

In addition to the main types, modifications have been made: modal viscose, polynose viscose, high viscosity viscosity, etc. viscose is very often mixed with wool, polyester, polyamide and other fibers. Beneficial features: sorption. Negative: crispy, dirty, low moisture.

Usage: cotton substitute, mixtures with a low sorption content. Free time; cold contact. Gained strength. Their manufacturing process differs from rayon by using an ammoniacal copper hydroxide solution for depolymerization. Another manufacturing method is similar - spinning is carried out in a bath with neutralizing acid, and the resulting fibers have an almost circular cross-section, and their properties resemble natural silk.

The length of the cotton fibers is generally just over 20 mm. Cotton fiber - thin but durable, dyes well. From cotton, a fine, uniform and strong yarn is obtained and a wide variety of fabrics are made from it - from the finest cambric and marquise to thick upholstery fabrics and car tire cord.

Textile fibers are also obtained from the stems and leaves of plants. Such fibers are called bast fibers. They are thin (flax, ramie) and rough (hemp, jute, etc.). Various fabrics are made from fine fibers, burlap, ropes and ropes from coarse ones.

The rotation takes place from the solution into the hot air chamber, the fiber profile is similar to rayon fiber. This is an expensive production where the base is made of cellulose. It is mostly made of multifilament, which often replaces natural silk. Uses: light silk type dresses, additions to woolen fabrics as an effect, clothing accessories, scarves, ties, etc.

The raw material is natural rubber or synthetic latex. Currently, the synthetic form is predominant, even if it is replaced by polyurethane fiber, which in recent times is on the rise. Rotation is carried out from circular profile glass nozzles into a water bath.

Wool has long been known to people. The bulk of the wool comes from sheep. In terms of its importance for the national economy, wool ranks second after cotton. It has many very valuable properties: it is light, does not conduct heat well and absorbs moisture well. In factories of primary processing, wool is freed from dirt and impurities. Fibers that are identical in their properties are combined into common batches. Smooth, thin yarn is made of wool, as well as fluffy, thick yarn. Smooth yarn fabrics are durable, lightweight, and wrinkle little. Sew of them different clothes- dresses, suits, coats. From fluffy and thick yarn, heavy fabrics (woolen) are produced, having a large thickness and a fleecy surface. Wool is the only natural fiber from which, by felting (entangling the fibers), various felts and other elastic and dense materials can be obtained.

Comparable characteristics table. Appearance: The fibers have a circular cross-section, slightly rough on the surface. Useful features: high flexibility, short-term recovery, roughness. Test questions What is viscous fiber, where is its area of greatest use and why? What environmental problems does the production of viscose fiber produce?

It is engaged in the production of steel wire to concrete, which uses wire concrete. Richard Voinar and asked him some questions. Director, please tell us what exactly do the wires for specific and what is their development? Their use makes significant savings in this segment of the construction industry. Through their use, increased concrete service life, better crack control and therefore lower costs for reinforcing concrete in general. The main purpose of these bonded fibers is to distribute the fibers evenly in the concrete and prevent them from tangling.

And natural silk is obtained this way. When the time comes for the silkworm caterpillar to transform into a pupa, and then become a butterfly, it releases a thin thread. With its help, the caterpillar attaches itself to a dry branch and weaves a shell out of this thread - a cocoon. Cocoons are collected, heated with steam and unwound on special machines. When unwinding, the threads of several cocoons (from 3 to 30) are connected, which are firmly glued together with a special substance - sericin, contained in the threads themselves. This thread is called raw silk. After rolling the raw silk, twisted silk is obtained, from which beautiful and durable knitwear is made.

What types of fibers do you manufacture here and where can they be used anywhere? The use is mainly used on industrial floors, where about 90% of our production is stored, as well as in prefabricated and other structural building elements. How is it possible that you are mainly producing loose fibers when the glue brings many benefits?

This is a feature of the Czech Republic. There is an increased interest in fibers, although these fibers are qualitatively and efficiently at a different level. Glued fibers have a smaller diameter and longer, thus reducing the dosage of these fibers in percentage. We call them high performance. For a simple idea, this is a bundle of 26-48 pieces of fiber bonded together with a water-soluble glue that dissolves 1-3 minutes after mixing with the concrete. The relationship between the number of fibers and their cost in cubic meters is, of course, much more advantageous in the case of glued fibers.

There is a fiber of mineral origin - asbestos (mountain flax), from which thermal and electrical insulation, fire suits, etc. are made.

The need for chemical fibers arose already in the 19th century. The planet's population grew rapidly, new branches of technology began to develop, consuming large quantities of fiber, and natural raw materials - cotton, wool, flax and silk - were in short supply.

The problem is that in the case of glued fibers, it is necessary to strictly adhere to the technological process of mixing these fibers with concrete. In some of us, this has not been successful, and some firms have quite the opposite experience in these streams. The biggest problem was the formation of fiber clusters called hedgehogs. Thus, companies have the impression that these clumps form much more with glued fibers than with loose fibers. This is a paradox, however, since the glued fibers were designed and manufactured precisely to ensure that these aggregates do not form in the concrete.

Two main types of fibers are called chemical - artificial and synthetic. The easiest for chemical technology late XIX- the beginning of the XX century. the creation of artificial fiber, obtained by chemical processing of natural high-molecular compounds, such as cellulose, the main component of wood, turned out to be. Great importance the creation of artificial fiber from cellulose was given by the great Russian chemist D.I.Mendeleev. He wrote: “A pound of ready-made fibers will cost less than a pound of cotton. In this alone, a great future is already visible ... "

There are no problems with glued fibers in Europe and they are widely used. In many cases in the world it has been proven that even with a very high dosage of these bound fibers in technological process no mess. These fibers were developed for superior design and offer previously unattainable levels of anchoring, tensile strength and fiber elongation for maximum performance. They can be used in construction to reinforce concrete in a number of new applications where this was previously not possible.

At the same time, this series is the ideal solution for applications where steel fibers and traditional reinforcement methods are combined. Typical applications of this series include screed, composite foundation slabs, underground concrete castings, highway structures, harbor and other storage yards, etc. it can be used very successfully for skirting boards, foundation meshes and even suspended structures. This custom fiber end provides perfect anchorage by keeping the fibers in place in the concrete.

Currently, viscose copper-ammonia, acetate and other artificial fibers are obtained from cellulose. They are used for the manufacture of staple and silk fabrics, cord and many other household and industrial products. Artificial fibers are cheaper than natural ones and surpass them in a number of properties. By changing the nature and modes of chemical processing of cellulose into fiber, it is possible to influence its strength, chemical resistance, elasticity, and thickness. However, the possibilities to change the properties of artificial fibers are still limited, since they are based on the same high molecular weight compound as natural ones.

As a result, the thread passes while the hook remains in place, increasing both the strength and the ductility of the concrete. The hook is so firmly anchored in the concrete that when it comes to deformations and tensile changes in concrete, the fiber can break into the straight part, but it can never be pulled out of its concrete ends.

Thus, you can imagine the potential that this topic presents. In this case, these fibers should be of great interest. Of course, this thread comes at a price and considers it right to use it during a long run. In the construction industry, this is certainly its application, but we have to find this application together with the designer first, and then from the project to the final decision. These fibers do not replace use in industrial floors, but especially in other structural systems.

A completely different matter is synthetic fibers, the production of which was only possible for modern chemistry. Synthetic fibers are produced by polymerizing relatively simple monomer chemicals. By using monomers of different nature and by targeting the polymerization reaction conditions and the spinning process from a melt or polymer solution, fibers with many predetermined properties can be synthesized. Raw materials for synthetic fibers practically inexhaustible - it is oil, natural gas, coal and coke oven gas, waste of pulp and paper, food and other industries.

It might be pretty good though. If an investor wants to meet this standard, he will be forced to use these high quality materials, since this condition is almost impossible with classic wires. The use of classic wires must then be combined with nets or wires. with a different kind of reinforcement.

Are you only focusing on steel fibers or are you using some other modifications? In addition to the classic steel fibers, we also supply polypropylene fibers, both micro and macro. Micro polypropylene fibers are used to ensure smooth curing of concrete. At the initial stage of cement hydration, a lot of heat develops and therefore the concrete shrinks. These fibers draw water out of the concrete, and then gradually and slowly release it, thereby preventing and reducing shrinkage.

Resistance to aggressive media, high mechanical strength, elasticity and other valuable qualities of synthetic fibers made them indispensable for use in modern technology. fabrics - this is not a complete list of the use of only one synthetic fiber - nylon. But now the industry produces dozens of brands of synthetic fibers - nylon, enant, lavsan, nitron ... And each the new kind fibers are new fields of application, sometimes the most unexpected.

Macropolypropylene fibers are fibers that replace conventional steel fibers at a lower dosage. But it can only be used in some applications. How different is it from your competitors? Every year he comes to the market with innovations based on many laboratory tests, so that he can truly guarantee everything he claims about his products. Therefore, our offer is much broader than other suppliers. We are a company that offers a complete solution for the strengthening of building structures, whether in the form of static calculations or direct on-site support.

The production of chemical fibers can be roughly divided into 4 stages. The first is getting the source material. If natural high-molecular compounds are used as raw materials for the manufacture of artificial fibers, then they are pre-purified from impurities. For synthetic fibers, this step consists in the synthesis of polymers. Then prepare the spinning mass. At this stage, the polymers are dissolved or brought into a molten state. Next, the solution or melt is thoroughly cleaned of undissolved particles and air bubbles, and dyes are added. The third stage is fiber spinning. This is the most important and responsible operation. The spinning mass is pushed through a spinneret - a disk with many small holes. The thin streams emerging from the holes are blown with air, and the fiber hardens due to the evaporation of the solvent or cooling of the melt. The latter is the fiber finish. The fibers are cleaned of impurities that have fallen on them during the spinning process. Often, at this stage, the fiber is also treated with a fat-containing solution to make it more slippery. This makes it easier to process the fiber in textile mills. The production of chemical fibers is completed by the operations of drying and winding the fiber onto spools and spools.

Our static calculations for building realizations are part of the supply, and we offer them to all subscribers completely free of charge. Of course, there are a lot of these buildings. These fibers are rarely used, mainly only where they can interact with weather conditions. If these fibers reach the surface, they can corrode. Terraces are in direct sunlight, and galvanized wires protect the life of the structure and preserve the aesthetic appearance work.

What are the delivery dates? We deliver our products within 48 hours of ordering all over the Czech Republic with free shipping. And what are your company's goals for the near future? They are quality extraordinary products and deserve the attention of the construction community.

The fiber is ready. Now his path lies in factories and plants, where it will turn into a variety of products.

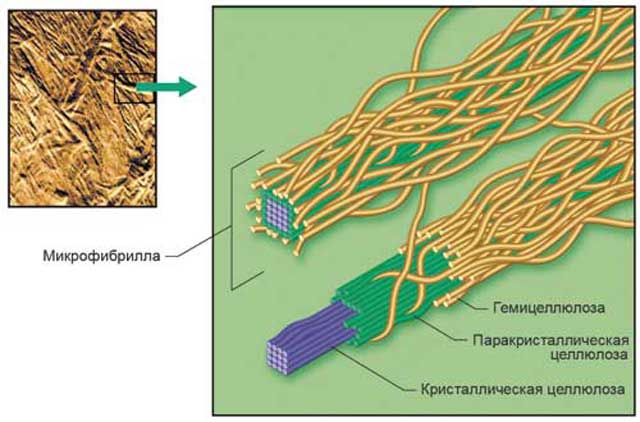

Cellulose is a fibrous material of plant origin and is the basis of all natural and artificial cellulose fibers. Natural cellulose fibers include cotton, linen, hemp, jute and ramie. Cellulose is a polymeric sugar polysaccharide composed of repeating 1,4-8-hydroglucose units linked to each other by 8-ester bonds. The strong intermolecular forces between chains, combined with the high linearity of the cellulose molecule, explain the crystalline nature of cellulose fibers.

Cellulose fibers

Natural fibers are vegetable, animal or mineral in origin. Plant fibers, as the name suggests, come from plants. The main chemical constituent in plants is cellulose and therefore they are also called cellulose fibers. The fibers are usually bound by a naturally occurring phenolic polymer, lignin, which is also often present in the fiber cell wall; therefore, plant fibers are also often called lignocellulosic fibers, with the exception of cotton, which does not contain lignin.

Cellulose is a fibrous material of plant origin and is the basis of all natural and artificial cellulose fibers. Natural cellulose fibers include cotton, linen, hemp, jute and ramie. The main artificial cellulose fiber is viscose, a fiber obtained by regenerating dissolved forms of cellulose.

Cellulose is a polymeric sugar (polysaccharide) composed of repeating 1,4-8-hydroglucose units linked together by 8-ester bonds.

Long, linear cellulose chains allow hydroxyl functional groups on each anhydroglucose unit to interact with hydroxyl groups on adjacent chains via hydrogen bonding and van der Waals forces. These strong intermolecular forces between chains, combined with the high linearity of the cellulose molecule, explain the crystalline nature of cellulose fibers.

Seed fibers

- Cotton is the most commonly used natural cellulose fiber. Cotton fibers grow from seeds in a capsule (pod). Each capsule contains seven or eight seeds, and each seed can have up to 20,000 fibers growing from it.

- Coconut fiber is obtained from the pulp between the outer shell and the husk of the coconut. It is a tough fiber. It is commonly used to make durable indoor and outdoor rugs, underlays and tiles.

- Kapok fiber is obtained from the seed of the Indian kapok tree. The fiber is soft, light and empty. It breaks easily and is difficult to spin. It is used like fiberfill and like pillow stuffing. In the past, fiber was used as filling for lifejackets and mattresses on cruise ships because it is very buoyant.

- Plant silk has properties similar to those of kapok.

Bast fibers

- Linen is one of the oldest textile fibers, but its use has declined since the invention of the rotating mechanism for producing cotton.

- Ramie fibers are 10 to 15 cm long. The fibers are whiter and softer than flax. Rami does not accept dyes well, unless it is dry cleaned. Rami strong natural fiber but it lacks stability, elasticity and elongation potential. It is resistant to mildew, insects and shrinkage. It is used for clothing, window treatments, rope, paper, and table and bed linen.

- Hemp hemp is similar to flax. The fibers are 10 to 40 cm long. Hemp has a low environmental impact: it does not require pesticides. It produces 250% more fiber than cotton and 600% more fiber than flax on the same plot of land. Hemp plants can be used to extract zinc and mercury contaminants from the soil. Hemp is used for rope, clothing, and paper. Hemp addicts are willing to pay an overpriced price for cannabis clothing because it is associated with marijuana.

- Jute is one of the cheapest and one of the weakest cellulosic fibers. Jute has low elasticity, elongation, sunlight resistance, mold resistance and color fastness. It is used to make sugar and coffee bags, carpet, rope and wall coverings. Burlap is made from jute.

Sheet fibers

- Pine fibers are obtained from the leaves of the pineapple plant. They are used to make light, clean, tough fabrics for clothing, bags and table linen. Payna is also used to make mats.

- The abaca is a member of the banana tree family. The fibers are coarse and very long (up to half a meter). It is a strong, durable and flexible fiber used for rope, floor rugs, table linen, clothing and wicker furniture.

Plant fiber classification

Plant fibers are classified according to their source in plants as follows:

(1) bast or stem fibers that form fibrous bundles in the inner bark (phloem or bast) of plant stems are often referred to as soft fibers for textile use;

(2) leafy fibers that run along the leaves of monocotyledonous plants are also called hard fibers and;

(3) seed hair fiber, a source of cotton, which is the most important plant fiber. There are over 250,000 species of higher plants; however, only a very limited number of species are used for commercial use (<0,1%).

The fibers in bast and leaf fibers are integral to the structure of plants, providing strength and support. In bast fiber plants, they are located next to the outer bark in the bast or phloem and serve to strengthen the stems of these reed plants.

The fibers are found in threads running along the length of the rod or between joints. To separate the strands, you need to remove the natural elastic that ties them together. This operation is called soaking (controlled decay). For most applications, especially textiles, this long composite type fiber is used directly; however, when such filaments are chemically comminuted, the strand breaks down into much shorter and finer filaments.

Long leafy fibers give strength to the leaves of some non-woody monocotyledonous plants. They extend longitudinally along the entire length of the leaf and burrow into tissues of a parenchymal nature. The fibers found closest to the surface of the sheet are the strongest. The fibers are separated from the cellulose by scraping, since there is little binding between the fibers and the pulp; this operation is called decortication. Fiber sheet filaments are also multilayer in structure.

Ancient people used rope for fishing, trapping and transportation, and in fabrics for clothing. The production of ropes and cords began in the Paleolithic times, as seen in the drawings of the caves. Ropes, cords and fabrics were made from reeds and herbs in Ancient Egypt (400 BC). Ropes, boats, sails, and rugs were made from palm leaf fibers and papyrus stems, while writing surfaces, called papyrus, were made from the core. Jute, flax, ramie, sedge, reeds and reeds have long been used for textiles and baskets. In ancient times, jute was grown in India and used for spinning and weaving. It is believed that the first real paper was made in southeastern China in the second century AD from old rags (bast fibers) from hemp and ramie, and later from mulberry bast fibers.

In recent years, the world markets for plant fibers have been steadily declining, mainly as a result of substitution with synthetic materials. Jute is traditionally one of the main bast fibers (tonnage basis) sold on the world market; however, the sharp decline in jute exports to India indicates a decline in market demand for this fiber, which is vital to the economies of India (West Bengal), Bangladesh and Pakistan.

Natural characteristics of cellulose fiber

Rami

Rami is one of the oldest fibrous crops, used at least six thousand years ago. It is also known as porcelain herb.

- Rami requires chemical treatment to remove the resin.

- It is a thin, absorbent, quick-drying fiber that is slightly stiff and has a high natural sheen.

- The plant is 2.5 m tall and has eight times the strength of cotton.

Hemp

Depending on the processing used to remove fiber from the stem, hemp can be naturally creamy white, brown, gray, black, or green.

- It is a yellowish brown fiber.

- Hemp fibers can be from 10 cm to 0.5 m in length, along the entire height of the plant

- The characteristics of hemp fiber are its superior strength and durability, UV and mildew resistance, comfort and good absorbency

Jute

Jute is one of the cheapest natural fibers and is second only to cotton in quantity and variety of uses. Jute fibers are composed mainly of plant materials cellulose and lignin.

- Jute is a long, soft, shiny plant fiber that can be unrolled into coarse, strong strands.

- Thus, it is a lignocellulosic fiber, which is partly textile fiber and partly wood.

- The plant grows up to 2.5 m and its fiber length is about 2 m.

- It is commonly used in geotextiles.

- It has good resistance to microorganisms and insects.

- It has low wet strength, low elongation, and is inexpensive to manufacture.

Coconut fiber

The fiber is mechanically extracted from the dry mature coconut husk after soaking.

- It is a long, hard and strong fiber, but with lower softness, less water absorption and a shorter lifespan than long soaked fibers.

Kapok

Kapok fiber is a silky cotton substance that surrounds the seeds in the pods of the ceiba tree.

- It can handle 30 times its own weight in water and only loses 10 percent of its buoyancy over a 30-day period.

- It is eight times lighter than cotton

- It is used as a heat insulator.

- It is also lightweight, non-allergic, non-toxic, rot and odor resistant.

- Since it is inelastic and too fragile, it cannot be spun.

- It has outstanding characteristics of lightness, tightness, thermal insulation and environmental friendliness.

- 19th World Festival of Youth and Students in Sochi 19th World Festival of Youth

- Circus burlesque performance

- A.N. Ostrovsky "Snow Maiden": description, characters, analysis of the work. Stage history of the play "The Snow Maiden Theatrical Snow Maiden Ostrovsky

- Theater of nations

- The meaning of the word vaudeville in the dictionary of literary terms Vaudeville in Russia

- Firebird in Russian motives and wireless electricity

- Dream-vision of prince andrei

- Characteristics of the puffer in the comedy "Woe from Wit"

- Postmodern literature

- ", Analysis of the novel by Chernyshevsky

- Ways of expressing the author's position at the bottom

- "Crime and Punishment": the history of the creation of the novel

- The image and characteristics of gerda in the fairy tale the snow queen andersen essay

- Olga mescherskaya light breathing

- “The image of Yuri Zhivago is the central image of the novel B

- Tool of labor or. Tools. Primitive tools of labor. Tools of labor during the Neolithic period

- Life principles of heroes in play A

- Balzac, Honore de - short biography Honore de Balzac's life years

- Shalamov analysis of stories Kolyma stories gravestone analysis

- Viktor Vasnetsov Artist biography