What is the fluffy yarn called? All types of yarn. What you need to know about yarn

Yarn is an essential element of knitting - if you do not take into account the needles and instructions, hand knitting yarn is a finished product. It is important to understand that whatever the quality of the yarn, it will certainly manifest itself in the knitted product, and even the most sophisticated needlewoman will not be able to put into the finished product a quality that the yarn does not possess.

Previously, not many types of yarn were sold and knitters knew all their basic properties. But the market has expanded enormously over the past few years: new types of yarns have been invented in addition to the traditional trio of wool, cotton and silk. New processing methods have been invented for traditional fibers, and thanks to innovative spinning and blending methods, new and interesting views yarn. Knowing what fibers the knitting yarn consists of, as well as the technologies for their manufacture, will help you choose the right yarn for the job.

There are two main types of fibers: natural and synthetic. Natural fibers are divided into animal fibers based on proteins - , , , , , and - and plant fibers based on cellulose - cotton, linen, ramie, sisal, hemp and jute. All animal fibers can be spoiled by moths whose larvae feed on fiber proteins. Synthetic fibers were invented after World War II and were made from various mineral sources. The only exception is viscose, which appeared much earlier. Viscose is made from waste wood and cotton fibers. Viscose is between natural and synthetic fibers, as it is produced artificially, but from natural material- cellulose.

Animal fibers

Wool(wool)

In a group natural fibers The main type in terms of volume of use, of course, is wool. It is so popular that some knitters call any yarn wool, regardless of what fibers the yarn consists of. Sheep wool yarn is warm, elastic, durable and dyes very well. Wool has excellent thermal insulation properties - woolen clothes are warm in winter and not hot in summer - which is why the clothes of Bedouins living in the desert are usually sewn from woolen fabrics. Wool fibers curl naturally, creating zones of still air that form an insulating barrier that prevents the fibers from matting. Wool can absorb up to one third of its own weight in water before becoming damp to the touch. The ability of wool to slowly absorb and release moisture enhances its insulating properties and also facilitates the dyeing process. In addition, woolen fibers can be repeatedly bent without breaking, and springy return to their original existence, because woolen fabrics are not only very wearable, but also almost do not wrinkle.

The surface of the wool fiber is covered with thin scales overlapped, like tiles on a roof. Under the influence of hot air, moisture or friction, the scales are connected, causing stalling and, finally, compression.

Wool differs depending on the breed and type of sheep. Virgin ( virgin wool or new wool) - Lamb wool obtained from the first shearing is very warm and soft. shetland wool spun from the wool of sheep from the Shetland Islands; the wool of these sheep is not sheared, but combed throughout the year. The name is applied to any loosely twisted two-strand wool yarn often used in jacquard knitting. It is made from very long and soft wool of Merino sheep. Wool Botany - fine yarn from the wool of Australian merino sheep; like Shetland wool, botani has become a common name for any very fine and soft wool yarn. Icelandic wool - a fluffy wool of medium thickness, usually used when knitting traditional Icelandic circular sweaters.

Merino wool (Merinowool)

This type of wool deserves special attention. Merino- a breed of fine-fleeced sheep, whose homeland is considered Western Asia. Subsequently, they spread to the countries Western Europe, North America and Australia. Today, only in Australia there are about 150 million merinos, while one sheep on average produces up to 15 kg of wool per year (other breeds of sheep 6-7 kg). The yield of pure wool is 35-45%.

Merino wool is homogeneous and consists of very fine (14-23 microns) and soft downy fibers. Merino wool is long - 6-8 cm, warm, soft, has excellent thermoregulating properties and, which is very important, does not irritate the skin. Due to the natural curls, it is elastic. Merino thread is even, smooth with a slight sheen - it fits perfectly into patterns and arans.

Merino wool is more expensive than regular wool. The price of the best batches of this wool (14-16 microns - the so-called merino extra fine) at annual auctions reaches several thousand dollars per kilogram.

Mohair (Mohair)

Mohair is the wool of Angora goats that live in Turkey in the Ankara region (formerly Angora), South Africa and the USA (Texas). Mohair is a very thin and warm fiber. It is one of the most durable natural materials yet exceptionally light and silky. The wool of Angora goats is uniform, usually white, but easily dyed in any color: from soft pastels to the most juicy. Dyed mohair looks bright and natural at the same time. Its natural luster does not disappear after dyeing, and the colors do not fade or fade for many years.

Mohair comes in three main types:

kid mohair (kidMohair) - the wool of a young goat up to 6 months, obtained during the first haircut. This is a thin (23-27 microns) and soft fiber with a length of 100-150mm.

Super kid mohair (Superkid)- kid mohair of the highest selected quality - the thinnest and most delicate fiber, silky and luxurious to the touch.

Mohair (Mohair)- wool of adult goats, it is thicker (up to 30 microns) and not as soft as the wool of kids.

It should be noted that modern technologies do not allow the production of yarn with a mohair content of more than 85%. To prevent the yarn from falling apart into individual fibers, mohair is usually mixed with wool, nylon thread or acrylic.

Alpaca(Alpaca)

Alpaca yarn is made from alpaca wool - one of the representatives of the camel family. Initially, alpacas were mistakenly assigned to the genus llamas, but in 2001 the taxonomy of the species was changed from lama pacos on the Vicugna pacos, finding out that the ancestors of the alpacas were vicuñas, not guanacos. Alpacas are bred in the highland belt of South America (Andes), at an altitude of 3500-5000m.

Alpaca wool has a wide range of natural colors: 24 different shades from black to white. From one individual, 5 kg of wool is sheared, they are sheared once a year. Alpaca fibers are long and shiny, and the yarns made from these fibers are warm and soft, with a subtle sheen. Living high in the mountains, where the difference between day and night temperatures sometimes reaches 30 degrees, alpaca wool has high thermoregulatory properties (it is warm in the cold and not hot in the heat). Alpaca wool is three times stronger and seven times warmer than sheep wool. Alpaca fibers have small curls that create air spaces and thus provide excellent thermal insulation. In addition, lanolin and other organic fats are completely absent in alpaca wool, which means that dust mites do not live in it. Since the yarn is hypoallergenic, it can be used to make children's products. Oil-free wool is also very resistant to dirt, so alpaca products stay clean for a long time.

Cashmere(Cashmere)

Cashmere fiber has become synonymous with luxury. Cashmere fibers are not sheared, but combed out from the underbelly of cashmere goats living in the mountains of China and Tibet, while one goat brings only 100 - 200 grams of fluff. Cashmere raw materials consist of threads with a thickness of only 13-19 microns (thin merino wool 14-23 microns, human hair - 50 microns), which makes it the thinnest and most delicate of all existing species yarn. It is also remarkably soft, supple and very susceptible to staining, however, cashmere does not retain its shape as well as sheep's wool, so 100% cashmere products can stretch under their weight. Because of this, and also because of the high cost of cashmere (a 25g skein of 100% cashmere costs 600-1300 rubles), it is often mixed with other fibers. Another advantage of cashmere is hypoallergenicity.

Camel's wool (camel)

Yarn from the wool and undercoat of a non-working two-humped camel - Bactrian - living in Central and East Asia. The most valuable is the Mongolian Bactrian wool. The coat of a camel consists of an outer coarse hair (25-100 microns) and an inner soft down (17-21 microns), which makes up 80-85% of the volume. Wool is not sheared, but fallen off is collected, up to 4-9 kg per camel. Camel wool is practical to wear, resistant to dirt and self-cleaning. It is very warm, protects well from moisture, and is also able to absorb and quickly evaporate it, leaving the body dry. In clothes made of camel hair, you will never sweat. In addition, it does not cause allergies and is able to relieve static stress.

Camel wool has unique healing and healing properties. Its dry heat and the organic matter have a beneficial effect on the skin, muscles and joints, improve blood circulation, promote vasodilation, activate metabolism and regenerative processes in tissues. Camel fiber cannot be processed chemicals, including bleaches and dyes, so camel wool yarn is produced in natural colors (14 colors: white, cream, beige, sand, reddish brown, dark brown, etc.). This serves as an additional guarantee of the ecological purity of these fabrics.

Angora (angora)

Angora rabbits are the most adorable of rabbits, reminiscent of a soft toy come to life. Their fur is unusually soft, fluffy and warm. Once upon a time, China, in response to Turkey's overpricing of the sought-after Angora goat wool, produced a softer and cheaper yarn called Angora. As it turned out, it was the fluff of wild rabbits, called angora. Then the Turks called the wool of Angora goats “mohair”, which in Arabic means “chosen one”. So these names were fixed for these types of yarn. Today, five breeds of Angora rabbits are industrially bred in the world: English, French, German, Giant and Satin. They differ in the size of individuals, the length of downy fibers, the density of the outer hair, color, and the volume of wool annually obtained (0.4-1.3 kg).

Angora wool products create unique comfort and therefore are very popular and in demand. However, angora wool also has its drawbacks: the loose fixation of the rabbit fiber in the yarn can cause fluff to come out, especially when it comes into contact with woolen things. In addition, it is necessary to protect the angora from excessive wetting and it can only be cleaned chemically. Despite the listed shortcomings, you can be sure that products from high-quality angora will serve you for more than one year.

Silk(Silk)

Silk belongs to the group of animal fibers because it has a protein structure. From the two spinning glands of the silkworm, a protein liquid is secreted, which, upon contact with air, hardens, turning into a filamentous fiber, from which the caterpillar builds a cocoon around itself. The length of one fiber can reach 1500m. After the caterpillar has twisted the cocoon, it is unwound, the caterpillar, unfortunately, dies.

Domestic silkworms feed exclusively on mulberry leaves and produce the finest, very smooth fibers, unlike wild ones, the fibers of which are rather coarse.

Silk has excellent heat-insulating properties, high elasticity, crease resistance, beautiful shine and good dyeing, but is prone to fading under the action of sun rays. The silk thread is very strong (it is not inferior to steel of the same diameter in tearing), but not elastic, so knitted silk products stretch a little when worn.

19.02.2012

Spin - twist a thread of fibers.

Yarn - a thread consisting of textile fibers connected by twisting. Yarn is used to make fabrics, knitwear, threads, etc.

Threads - twisted products made from cotton, wool, linen yarn, raw silk, chemical threads. There are sewing, embroidery, knitting and darning threads.

Any yarn can be used for knitting, but tightly twisted thread is not suitable for knitting. The fabric will be stiff and may warp. Tightly twisted yarn is best used for crocheting.

The properties of the fibers determine the properties of the yarn, and in the future, the properties of the products. It is good when buying or creating any things with your own hands, to know what characteristics this thing will have.

At present, with the advent of modern technologies, new types of fibers and yarns appear, this article contains material on the most famous ones.

Fibers are divided into natural and chemical. Natural fibers of animal origin are wool (sheep, alpaca, llama, vicuña, camel, cashmere, angora, mohair), and silk. Natural plant fibers are cotton, linen, hemp (hemp), ramie, jute, abaca, agave, kenaf.

Chemical fibers are divided into artificial and synthetic. Artificial chemical fibers (cellulose) are obtained from plant materials - these are viscose, modal, lyocell, cupra, acetate, triacetate; bamboo. Artificial protein fibers are corn, soy. Synthetic chemical fibers that are obtained from petroleum products are polyester, polyamide, polyacryl, polyurethane, etc. By processing, you can get threads that mimic silk, cotton or wool.

Cotton.

Co - Cotone/Cotton/Baumwolle/Coton/Cotton

Receipt. Cotton yarn is obtained from the fiber covering the cotton seeds. The quality depends on the length of the fiber - the longer it is, the better the cotton; on the processing method. The yarn is produced in natural bleached and mercerized form.

Mercerization - treatment with a solution of caustic soda (usually at 15 - 18 ° C.) with simultaneous stretching of the fiber. The name is given on behalf of the English inventor J. Mercer (1791 - 1866).

Finishing is a processing method in which new properties appear, for example, rigidity, crease resistance. With the help of processing, it is possible to impart water-repellent properties, oil-dirt-repellent. The essence of the method is that the fabric or threads are treated with a liquid preparation, then dried.

Properties. Cotton fabric is durable, soft, pleasant to the body, comfortable to wear, heat resistant, absorbs moisture well (20 - 65% of its own weight) and does not seem wet, does not cause allergies, is not afraid of alkalis, but is destroyed by acids.

Cotton is a heavy material that is not resistant to bacteria and microorganisms: it rots and molds from a long stay in dampness.

Natural (= untreated) cotton is dyed only in faded colors (such properties it has).

Mercerized cotton is well dyed in bright, juicy colors, slightly shiny, i.e. improves appearance, has greater tensile strength, but it is less stretchable and more prone to shrinkage after drying.

With the help of a special treatment - sizing, cotton can be made wrinkle-resistant and non-shrinking.

care requirements. Cotton fabrics they hold dirt more firmly than others, since the fibers have a loose, bumpy surface, particles of dirt on such a surface are held more firmly.

Cotton items that can be boiled can be washed in washing machine at a temperature of 90°C, colored linen - at 40°C.

Drying in the machine is possible only with the permission symbol.

Items should be ironed slightly damp. The temperature regulator of the iron must be set to the temperature value in accordance with the recommendations indicated on the label, because. these numbers depend on the fiber processing method (mercerization, sizing).

Linen.

Li - Lino/Linen-Flax/Flachs, Linen/Lin/Linen

Receipt. Yarn is made from fibers found in the flax stem. The process is labor intensive and more expensive than the production of cotton yarn.

Properties. Linen fabric absorbs moisture well, dries quickly, so it is very comfortable in hot climates. The thermal conductivity of linen is higher than that of cotton. It has been proven that in subtropical conditions, the temperature of a person under clothes made of linen is 3-4ºС lower than under clothes made of cotton.

High-quality linen cloth has a smooth surface with a matte sheen. The fabric is durable, linen yarn is even stronger when wet than when dry. Therefore, linen was used to make fishing nets, sea ropes and canvas for ships.

Linen does not accumulate static charge. It is believed that linen underwear is more useful to wear than cotton, and sleep is better on linen pillows and sheets.

Linen has antibacterial properties, inhibits the growth and reproduction of fungi and bacteria, the use of linen clothing eliminates various types of irritation on human skin.

Linen is a little elastic, very wrinkled material, more rigid than cotton.

care requirements. Linen fabric does not require special care, it tolerates boiling well. Can be washed and ironed at high temperature. Ironing should be slightly damp. When dried in the machine, linen can shrink a lot.

Hemp.

AB - Manila (Abaca)/Abaca (Manila hemp)/ Manila hemp (hemp)

CA - Canapa/Hemp/Hant/Chanvre/hemp fiber, hemp

Receipt. The yarn is obtained from hemp stem fibers. The fibers are yellow-brown or Brown color, are difficult to bleach, but at the same time they are well dyed in bright and dark colors.

Properties. Externally and to the touch, hemp material is very similar to linen, but it repels water better. The yarn has high wear resistance, low elastic properties, easily wrinkled.

Rami.

RA - Ramie / Nettle (ramie)

Receipt. Produced from a shrub growing in South-East Asia, China, Japan, Southern Europe. This is Chinese nettle.

Properties. The color is white, the thread is shiny, like silk. The fibers are long, stretch poorly, but have high wear resistance: 5 times higher than that of cotton, 2 times higher than that of flax. The cloth is perfectly painted, without losing at the same time gloss. Ramie fibers, like linen, absorb moisture well and dry quickly, are resistant to bacteria, mold fungi, but have low elasticity. Ramie is a very wrinkle-resistant material, stiffer than linen.

care requirements. Can be washed and ironed at high temperature. Ironing should be slightly damp.

Wool.

WO - Lana/Wool(sheep`s wool)/Woole/Lane/Laine/Wolle/sheep`s wool

Receipt. The term wool in the textile industry is understood as sheep hair, if the wool of another animal is used for the production of yarn, then the name of the yarn will contain the name of the animal.

Wool is divided into types, depending on the method of obtaining and the quality of the raw material. All information can be obtained from the designations on the labels.

The designations "Reine Wolle" (refined wool) or simply "Wolle" refer to low quality wool or regenerated wool, which is made from recycled wool.

The designation "Schurwolle" (shorn wool) is used if the wool is obtained from shearing healthy live animals and contains no more than 7% foreign fibers.

The designation Reine Schurwolle (purified sheared wool) indicates that the wool contains no more than 0.3% impurities. Manufacturers of such wool use the Woolmark symbol, which indicates that the product complies with international quality standards, this symbol indicates that the wool is obtained by shearing live healthy animals, as free of impurities as possible, i.e. is of high quality.

The Superwash designation indicates that products made from such wool can be washed in a washing machine.

The designation Lambswolle indicates that the wool comes from the first shearing of a young six-month-old lamb. Woolen hairs have not yet coarsened, wool is not tear-resistant, but tender and soft, caressing the skin.

The designation Merino indicates that the wool is obtained from special breeds of sheep - Merino. The best Merino sheep breeds are bred in Australia and New Zealand, this is due to natural and climatic conditions.

Merino wool is understood as sheep hair with a thickness of 14 to 22.5 microns, depending on the thickness of the hair, it is further subdivided into 4 subgroups.

The first subgroup does not have its own name. It includes wool with a hair thickness of 14 - 15.5 microns. This is the so-called "summer wool". The volume of production is extremely small. It is used exclusively for the production of the most expensive types of fabrics and knitwear. Due to the use of the finest woolen raw materials, the thread is very thin and products made from such yarn can be worn in the summer along with cotton items. Things made from such yarn are very light.

The second subgroup is called Extra fine (literal translation - especially thin) - hair 16-17 microns thick. Share in world production - 5-7%.

The third subgroup Super Fine (literal translation - very thin) - wool with a hair thickness of 18-20 microns. Production volume - up to 15%.

The fourth subgroup is Merino hair with a thickness of 20 - 22.5 microns. This type accounts for up to 80% of world production.

Use in hand knitting yarn is limited by the cost of this raw material, a yarn that feels the same but is made from 25 micron wool. It will cost a lot less.

With the age of the animal, as the herd degenerates, the thickness of the hair increases and reaches 28-30 microns. It turns out that the wool sheared from a Merino sheep is Merino only by the breed of the animal, but not by its characteristics.

Wool is a product of animal origin. The quality depends not only on the breed, but also on the age of the animal, on the conditions of detention, nutrition, climatic conditions.

Properties. Woolen fabrics almost do not wrinkle, retain heat well. It is enough for clothes to hang a little in a damp room for the fabric to smooth out and the smells to disappear. Wool dries slowly. It has the property of falling off, which must be taken into account when caring for products, but this property can also be used to make denser products.

care requirements. Wool must be washed with detergents for delicate or woolen fabrics, by hand. The water temperature during washing should not exceed 30°C. Washing should be done in in large numbers water. Wool does not like long soaking, a smell may appear, this is due to the structure of the hair, which is hollow inside. Woolen products are not rubbed and not twisted, not squeezed out, but rolled up in a towel, then laid out to dry. Dry woolen clothes in a well-ventilated area, away from heaters, in the shade from the sun, and cannot be dried in a typewriter. Many products are best given to dry cleaning. It is necessary to iron in the "wool" mode, with steam or through a damp cloth.

Alpaca

WP - Alpaca/Alpaka/alpaca wool

Receipt. Alpaca is one of the representatives of South American camels.

Alpacas live on the high plateaus of South America at an altitude of 4 - 5 thousand meters in extreme climatic conditions. There is very strong solar radiation, cold winds blow and sharp temperature drops are observed: from -20 ° C at night to + 15-18 ° C during the day. To survive in such conditions, alpacas must have a special coat: light, thin, soft and at the same time so dense as to not let water through. Especially valuable is the suri alpaca wool, which are considered high-bred animals. Suri's hair falls down the sides like a mane. It is longer, shiny and straight than other alpacas, which is why it is so highly valued. However, suri are unsuitable for breeding in livestock farms, so their share in the total volume of alpaca wool is only 15%.

Alpaca yarn is significantly more expensive than ordinary wool, and when using standard fiber it is much stiffer than the latter; the use of alpaca with a hair thickness of about 20 microns, i.e. much thinner than usual, making the yarn incredibly expensive. Of great interest is the yarn from a mixture of 20 micron wool, cashmere and alpaca in equal proportions. However, this yarn can cost 3-4 times more than regular wool yarn.

Alpaca haircuts are experienced every two years. At the same time, they are never sheared, like sheep, "naked", because in the complete absence of hair, animals in such harsh climatic conditions will simply freeze. Therefore, the collection of wool for one haircut is not so high: a maximum of 3.5 kg of wool is sheared from one animal, and even half a kilogram less from suri. This naturally melange wool is sorted exclusively by hand.

Almost everything that can be said about alpaca wool can be attributed to the wool of another animal of the camelid family - vigonii.

Properties. Thin, soft, has an elegant sheen. Processed alpaca wool is stored for a long time, without losing its natural qualities and virtues, and is used only in high-quality expensive materials. coat and outerwear from alpaca are not exposed to moisture, give cozy warmth and ease. Due to the fact that the individual fibers of wool are long, alpaca wool does not fall off and practically does not form spools.

care requirements. It is enough to brush it lightly with a brush and hold it for a while. fresh air and it will be like new again. Alpaca wool products can be dry-cleaned.

Lama

WL - Lama/Liama/Lama wool fiber

Receipt. Wool of the South American semi-wild or partially domesticated llama. Shearing is done every two years and brings 2 - 3 kg of raw material from the animal. Llama wool is often used in expensive outerwear.

Properties. Perfectly retains heat, light, soft and fluffy, has a rich color range. The yarn from this wool is dense, so pellets do not form on the product.

Camel's wool.

WK - Camello/Camel/Kamel/Chamean/camel wool

Receipt. Camels have a dense coat of hair that reliably protects them from the harsh climate and sudden changes in temperature. Camel hair is not sheared. It gathers during molting in early summer. From one animal per year you can get up to 5 kg of wool. The best wool is combed from non-working camels, because it is the thinnest.

Properties. Camel hair removes static electricity and is not electrified. It practically does not bleach and therefore comes in a natural color, dark or black. A young camel up to one year old - white color

Kashmir.

WS - Kashmir/Cashemire/Cashmere/Kaschmir/cashmere

Receipt. The starting material for this yarn is the hair of Tibetan mountain goats, obtained by combing. Cashmere goats live in the mountains at an altitude of 5000 m and have a wonderful dense coat. The output of down, cleaned of awns, is very small - from 100 to 200 grams per year per animal. High-quality cashmere down is one of the most expensive natural materials.

Properties. Cashmere comes in white, grey, brown and black natural colors. In order to dye wool, the original color is first etched out, which leads to a deterioration in quality: the wool becomes stiffer and loses elasticity. Cashmere goat yarn is very light, warm and soft, but too susceptible to friction and pilling, so cashmere is usually blended with wool fibers in different proportions.

care requirements. Knitwear containing cashmere must be hand washed with gentle detergents at a temperature not exceeding 30°C. It cannot be pressed or twisted.

Angora.

WA - Angora/Angora (karin)/rabbit wool fiber

Receipt. This is the fur of the angora rabbit. The fluff is combed out twice a year.

The history of the origin of the name “mohair” and “angora” is interesting. In ancient times, goats, from whose wool they obtained what we now call “mohair”, lived in only one region, which was called and is now called “ANKARA”. The yarn obtained from the hair of the “golden” goats was called “ankora” or “angora” outside of Turkey. The export of these goats outside Turkey was just as strictly prohibited as the export of silkworms from China. The effect of this ban was also facilitated by the fact that these animals, and of course they were smuggled out, did not take root anywhere else. Attempts to produce an analogue of the real angora were constantly made. The Chinese were the most successful in this - they began to produce yarn, outwardly resembling the original, from rabbit fluff, and they called it “angora”. Around the same time, England began to buy real angora from Turkey and the yarn produced in England from this raw material was called “mohair”. Nowadays, these names have stuck: mohair is that from a goat, and angora is from a rabbit. It is also noteworthy that now there are only three regions in the world that supply mohair to the world market - Ankara in Turkey, South Africa and Texas in the USA. These goats never took root anywhere else.

Properties. High quality woolen hair is 6 to 10 cm long. Shorter hairs are very difficult to keep in the thread when spinning and twisting. It is this not very high-quality wool that falls out or “crawls out” of cheap woolen products. Modern, hybrid bred in Germany, angora rabbits have a long pile with amazing luster and a high heat retention coefficient. These animals are shorn five times a year and receive 900 - 1000 grams of high-grade wool from each haircut. Despite their thinness, angora hairs are very strong. Angora wool is most commonly used in combination with other wools and synthetic fibers in knitwear. New weaving technologies have made it possible to use angora wool in modern woven materials. IN pure form it is practically not used. Firstly, because it is quite expensive, and secondly, because it is completely inelastic. However, angora is just perfect when mixed with sheep or merino wool, acrylic. It gives products warmth, softness and lively hairiness.

care requirements. Products with angorka cannot be washed, and it is better not even to wet, only chemical washing is acceptable. In general, there is an opinion among experts that an angorka product is a thing until the third wash. However, it must be noted that things knitted from very expensive yarn with angora last for years.

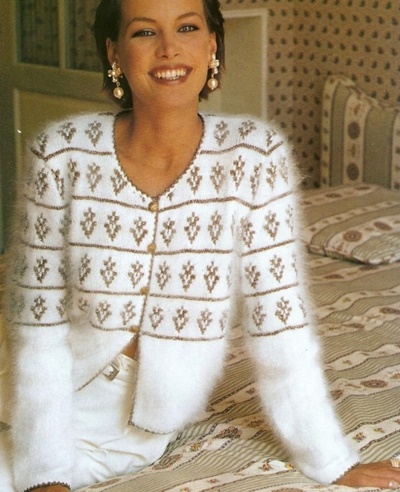

Mohair.

WM - Mohair / mohair / angora goat wool

Receipt. This yarn is obtained from the wool of the angora goat. Straight fibers, with a single fiber length of 120 - 300 mm, almost do not roll. The most modern technologies do not allow the production of yarn with a mohair content of more than 83%, since in order for this yarn not to fall apart into individual fibers, slippery goat hairs must be fastened together.

There are only three regions in the world that supply mohair to the world market - Ankara in Turkey, South Africa and Texas in the USA. These goats never took root anywhere else.

Properties. Products made of fabrics, which include mohair wool, have a peculiar smoothness and noble sheen and silkiness. Mohair is a great heat regulator. Fabrics containing a high percentage of quality mohair are very durable, but require special care and are difficult to sew. Kid-Mohair is the wool of a young Angora goat, especially gentle and flowing like silk hair. Mohair wool is quite expensive and is most often spun with wool or man-made thread. Mohair is well dyed, easily cleaned of dirt.

care requirements. Wash it very carefully so as not to lose the "fluffiness".

Silk.

SE - Seta/Silk/Seide/Soie/silk

Receipt. Natural silk fiber is obtained from silkworm cocoons, that is, caterpillars that are found in nature or specially bred by humans. The highest quality silk is considered to be twisted silk from long threads extracted from the center of the cocoon. The length of such a thread can even reach one kilometer.

Properties. Silk clothes are pleasant to wear in any weather. It warms in the cold and cools in the heat. Any silk fabric absorbs moisture in an amount equal to almost half its own weight, and at the same time does not seem wet to the touch. Silk quickly evaporates moisture from the surface of the skin. However, sweat can cause indelible stains that make silk brittle. Depending on the quality, type of weave and finish, silk fabrics are very light and soft or heavy and stiff. Accordingly, they crumple more or lesser degree. The disadvantage is their low light fastness.

care requirements. Silk clothes are recommended to be dry-cleaned. It is mandatory for products made of taffeta, silk brocade, chiffon, organza, silk satin and georgette. Printed and dark silk fabrics are also better to be cleaned, as silk sheds heavily when washed. Wash it by hand at 30°C with a mild detergent. Do not rub the silk fabric with your hands, wring it out or twist it. First, silk should be rinsed well in warm, then in cold water. At the end of the rinse, you can add a little vinegar to the water - this refreshes the color. Silk should not be dried by machine, as well as in the sun or near heating appliances. Wet silk products should be carefully wrapped in a cloth and lightly squeezed out the water. Iron silk with a moderately heated iron in the "silk" mode from the wrong side, in a slightly damp form. When ironing, the fabric must not be sprayed: this may cause stains on it.

Viscose.

VI - Viscosa/Viscose/Viscose

Receipt. Viscose fibers are the most natural of all chemical fibers. Fibers are obtained in the process of regeneration of cellulose from softwood (spruce, pine) by reaction with sodium alkali and carbon disulfide. Cellulose dissolves in water and forms a viscous mass. The streams of viscose passed through small holes become viscose fibers during hardening. Thus, viscose is a natural cellulose without impurities. Modern complex chemical processes give a huge range of viscose fibers of various basic qualities. Depending on the purpose, they are made with a shiny or matte surface. Viscose fabric can be given the appearance of silk, cotton, or wool by changing the sheen, thickness of the fibers, or "curling" them. For example, thickening and nodules on the fibers can give it the appearance of flax. Viscose is soft, with a silky sheen, absorbs moisture well. It is used in a mixture with other materials, most often with elastane. It gives viscose fibers elasticity, and they do not wrinkle so much. Viscose products are easy to wash, but they must be handled with care.

Properties. Viscose fibers absorb moisture better than cotton, but they are less durable when wet and not as wearable. Viscose products should not be twisted, because fibers that are fragile when wet can break and there will be a moss effect from the ends of broken fibers. Viscose becomes stiff when wet.

If a continuous viscose thread is cut to a certain length, similar to the length of a cotton or wool fiber, then we get a current called “staple” fiber, and yarn and fabrics from them are called “staple”.

Viscose fiber is soft, not elastic, so the products from it are flowing. By adding viscose fiber to other fibers, the blended fibers partially acquire the properties of viscose too.

care requirements. It is recommended to wash viscose by hand or in a machine in a gentle mode at 30 - 40 ° C with a washing powder for delicate fabrics. Viscose fabrics should not be rubbed, twisted or spun in a spin, they can be hung to dry completely wet or rolled up in a sheet and gently wrung out. They are also not allowed to dry in the machine. Iron viscose with an iron in the “silk” mode when wet or through a damp cloth. Products made of viscose fabric can be dry-cleaned.

Modal.

MO - Modal / Modal (long staple cotton)

Md - Modal/Moadal/Modal/Modal/modified viscose fiber

Receipt. A fiber obtained from beech pulp. A more modern version of viscose.

Properties. Modal products are pleasant, silky to the touch, absorb moisture well, "breathe", do not shrink when washed, retain their shape, have a soft sheen, retain the intensity of colors for a long time, and do not cause allergies. In terms of physical and chemical properties, modal can be compared with cotton. Products made from it are more durable than those made from viscose. Mixed with cotton, it gives the fabric a subtle sheen and an elegant look. The cotton-modal blend replaces the cotton mercerization process.

care requirements. When washing, it is advisable to turn the product inside out and avoid the use of bleaching agents, as they cause the material to roll.

Lyocell.

LO-LYOCELL

Receipt. Fiber from cellulose of eucalyptus trees. Viscose of new generation. Gives a cottony feel when worn.

Properties. Lyocell is a silky and soft fiber, when wet it is three times stronger than viscose; does not roll, stains well, has a soft sheen, breathes and absorbs moisture well. In the production of lyocell is used in different compositions, such as lyocell with elastane, lyocell with modal and elastane. The surface of fabrics made of tencel (= lyocell) resembles dense wet silk and has an ashy hue.

care requirements. Wash at 40°C, iron inside out.

Cupra.

Cu - Cupro/Cupro/Cupro/Cupro/copper-ammonia fiber

Receipt. Cupra threads are made from cotton cellulose. It is dissolved with copper salt and ammonia (from Latin cuprum copper - copper), then endless threads with a matte sheen are spun from this mass, which are very reminiscent of natural silk. The fiber is very fine and smooth. This is the most noble, high-quality and expensive fiber based on cellulose. The production process is environmentally dirty and is characterized by a significant consumption of expensive copper.

Properties. Cupra fabrics behave like silk: they absorb moisture well, breathe well, are pleasant in the heat and warm in the cold. Drape well.

care requirements. For cupra fabrics, it is recommended to machine wash in a gentle mode at a temperature of 30 - 40 ° C or hand wash with products for delicate fabrics. They can not be rubbed, twisted or rinsed strongly, dried in the machine. Iron the fabric after complete drying from the wrong side in the “silk” mode.

Acetate and triacetate.

AC - Acetato/Acetate/Acetat/Acetate/acetate fiber

TA - Triacetato/Triacetate/Triacetat/triacetate

Receipt. Unlike viscose, acetate and triacetate fibers do not consist of pure cellulose, but of cellulose acetate (cellulose waste).

Properties. Acetate and triacetate silk fabrics have a slightly shiny surface and are very similar in appearance to natural silk. They perfectly retain their shape and almost do not crumple. Acetate silk does not absorb moisture well (only 6% of its own weight), but dries quickly. It does not tolerate high temperatures (melts at 210°C) and dissolves in acetone. Triacetate silk absorbs even less moisture than acetate, but has greater heat resistance (melting point about 300 ° C) and retains its shape well when pleated.

care requirements. Triacetate silk tolerates normal machine washing at temperatures up to 70 ° C and ironing in the "silk / wool" mode. Otherwise, triacetate silk is treated in the same way as acetate silk. Viscose mixed with acetate is used as a lining. For acetate silk, hand or machine wash at 30°C on a delicate cycle is recommended. Chemical cleaning is possible. Under no circumstances should clothing made of acetate silk be dried in a machine; it must be hung up to dry. Acetate silk dries quickly and does not need ironing. If you still want to iron it, do it from the wrong side with a barely warm iron.

Bamboo.

Receipt. Bamboo fibers are obtained in two ways.

1st way. Cellulose is obtained from bamboo leaves and stems, then threads are produced from cellulose. The process is similar to obtaining viscose. Such yarn is labeled "bamboo vicose" or "bamboo rayon", which means "bamboo viscose" or "bamboo rayon".

2nd way. It consists in the mechanical crushing of the stiffened parts of the bamboo plant, softening the mass, drawing out natural fibers from this mass. The process is similar to obtaining flax fibers. This yarn is labeled "bamboo linen", which means "bamboo linen".

The second method is more laborious, but does not pollute environment, the resulting fiber is natural.

This fiber appeared on the Russian market quite recently. Meanwhile, in the East it is distributed no less than cotton.

The structure of mechanically obtained bamboo fiber makes it more valuable.

Properties. Bamboo fiber has a natural luster, is softer than cotton and feels like silk to the touch. Fabric made of bamboo fibers does not cause irritation, has natural antimicrobial and deodorizing properties, contains a component of bamboo kun, which prevents the growth of bacteria and, as a result, prevents odors.

It has been experimentally established that more than 70% of the bacteria present on bamboo fiber die.

Bamboo fiber underwear is very comfortable due to its unusually porous structure. Moisture from the surface of the skin is instantly absorbed by the tissue and evaporates. This property of bamboo fabric is even more pronounced than that of cotton.

Bamboo is close to linen in terms of pleasantness and usefulness in wear.

Bamboo yarn is very soft, gentle to the touch, comfortable to wear. Products give a feeling of coolness and comfort in the hot summer

The canvas absorbs 3 times more moisture than cotton, reduces the harmful effects of the sun, poorly transmitting ultraviolet rays.

When washed, it behaves like cotton.

Bamboo yarn fits well in knitting, the loops are even and neat, after washing the fabric turns out to be flowing, but stretches after washing. This should be taken into account.

care requirements. Treat like cotton products.

Soy.

Soy fibers are environmentally friendly. Knitwear of them in their own way appearance similar to silk, in terms of hygroscopicity - with cotton, and in terms of thermal protection - with cashmere.

Studies have shown that soy fibers have unique antibacterial properties, maintain natural body temperature, have a beneficial effect on human skin and improve its energy balance.

Corn fibers.

Corn fibers (ingeo) are produced in an environmentally friendly way. When pure, these fibers are oily and silky to the touch, but when mixed with, for example, wool, they take on the characteristics of wool. They are beautifully woven, better than wool and cotton.

Polyester.

PES - Polyester

PL - Poliestere/Polyester/Polyester - polyester, polyester fiber

Receipt. The raw materials for the production of polyester fibers are oil and coal tar. It is produced in the form of threads (polyester silk) and staple fibers for blending with other fibers. In various countries it is produced under brand names: lavsan, terylene, dacron, lanon, diolene, tergal, etc.

Properties. The fibers are characterized by high elasticity, light resistance, withstand high temperatures. They have low hygroscopicity, poorly stained. They have increased rigidity, are easily electrified and peeled. These shortcomings can be eliminated in the production of ultra-thin microfibers (mickofibre). Now polyester fibers are used mainly for technical purposes and for the production of sewing threads. In high-quality yarn for hand knitting, they are practically not used. Polyester is characterized by the highest wrinkle resistance. Superbly clean and easy to wash. The fiber is thermoplastic, thanks to which the products retain the pleated and corrugated effects well. In terms of resistance to abrasion and bending, it is second only to kapron fiber.

care requirements. Polyester is machine washable at 40°C. Some polyester fibers tolerate temperatures as high as 60°C. Higher heat can create creases in the fabric that are then very difficult to remove. White fabrics should be washed with a universal powder, colored fabrics with a powder for delicate fabrics. Polyester can only be dried slightly in the machine at a low temperature, but in no case dry. In this case, it is necessary to follow the care instructions indicated on the label so that hard-to-remove creases do not appear. Polyester jersey is dried only in the unfolded form. Polyester does not require ironing, but if it is needed, it is necessary to iron with a moderately heated iron (in the "silk" mode) and through a damp cloth. Polyester items can be dry-cleaned.

Polyamide.

Ny - Naylon/Polyamide

PA - Polyamide

Receipt. Fibers are obtained by polymerization of distillation products of oil, natural gas and coal. The most famous of them: capron, nylon or nylon, perlon, silon, dedron. On the labels of knitting yarn, very often they simply write: “polyamide”.

The most famous polyamide microfibers are taktel, meryl, cordura, saplex.

Properties. Polyamide fibers- the most durable of all textile raw materials in terms of tearing and abrasion. Due to its excellent strength in combination with wool and cotton, polyamide gives fabrics strength and stability. Cloths do not lose their shape during wet and dry operation.

The fibers are well suited for the production of products that require special strength and reliability in operation: all types of hosiery, sports knitwear, swimwear, overalls, braided cords, braid, twisted products, technical goods: fishing lines, tackle, container and packaging products, elastic bands and many others.

However, the fibers have low hygienic properties, glassy luster, high electrification, instability to light (yellowing and becoming stiff), brittleness with repeated washings.

care requirements. Same as polyester. But polyamide fiber is more sensitive to heat, so it must be washed at a temperature not exceeding 40 ° C. Iron polyamide at the lowest heat and without steam.

polyacrylonitrile fibers.

PA - Acrilica/Polyacrylic/Polyacryl/Acrylique/Acrilico/Acrylic/acrylic

PC - ACRILICO/ACRYLIC/ACRYL/ACRILIQUE/Acrylic

Receipt. The initial products for the production of this group of fibers and threads are acetylene and hydrocyanic acid, which are obtained from natural gas. They are known on the world market under the following names: PAN fiber, acrylic, nitron, orlon, prelana, krilor, redon, etc.

The most famous fabrics are acrylic, nitron, curtel and orlon.

Properties. The most soft, silky and "warm" synthetic fiber. They have high strength, thermoplasticity, high light resistance, do not fade, do not fade. Acrylic is currently the best wool-like fiber, which is close to natural wool in its properties. Acrylic is superior to wool in heat-shielding properties. But in terms of abrasion resistance, it is inferior even to cotton. It has low creasing and shrinkage, low hygroscopicity, it is highly electrified and pilled, but the pellets disappear during wear due to low strength properties. Acrylic fibers and threads are deeply and firmly dyed, providing a magnificent pure color: snow-white, deep black “under the velvet”, bright all the colors of the rainbow and a huge palette of delicate tones and halftones of a fashionable range of colors.

Acrylic yarn knits beautifully on knitting machines.

care requirements. These requirements are the same as for polyester, but the products should be washed at a temperature not exceeding 30 ° C. Drying by machine is excluded.

Elastane.

Ly - Laychra/Laycra/Lycra

EL - Comma/Bubber/Elastodien/Elastodiene/Elastan/Elasthan/Elasthanne/Elastane

Receipt. LYCRA refers to general class man-made elastane fibers (known as "spandex" in the US and Canada) and is technically defined as segmented polyurethane. This fiber consists of "soft" or flexible segments connected to each other by "hard" or rigid segments. This gives the fiber its inherent long-lasting elasticity. These highly elastic fibers are able to stretch seven times and then retract back to their original length. Elastane fibers are typically used as fabric additives and are almost never used in their pure form. SPANDEX is the American name for elastane. The addition of elastane to fabrics and knitwear improves consumer properties, but at the same time increases the cost of products.

Properties. Elastane fibers make fabrics elastic and, like synthetic fibers, give them durability. Fabrics with the addition of elastane fibers are very durable, retain their shape and color, almost do not wrinkle and do not require special care.

All types of hosiery become softer, conform to the shape of the leg and last longer thanks to LYCRA. A small amount of LYCRA gives all types of clothing an improved fit, a more pleasant feel, an improved appearance.

Knitwear with LYCRA retains its shape with repeated use and wrinkles and bruises are easily eliminated on them.

When knitting from yarn containing LYCRA, it must be taken into account that the fabric shrinks when steamed. Shrinkage can reach 50%. Therefore, before you start knitting, you need to knit a sample and steam it with a regular steam iron.

care requirements. For all fabrics with elastane fibers there are general rules- when washing, use powders for delicate fabrics and do not dry in a machine. The temperature during washing and ironing is determined chemical composition fabrics.

Microfibres.

Receipt. These are endless threads or fibers ten times thinner than silkworm threads. Fabrics such as belset, taktel, diolen are obtained from polyester or polyamide fibers.

Properties. The fibers are processed into extraordinarily fine yarn, from which they are woven so dense fabrics that they become impervious to wind and rain, but at the same time let moisture (sweat) evaporate from the body, that is, they contribute to good air exchange of the skin. Since they do not absorb moisture, but pass it outside, where it evaporates, clothes made from such fabrics are always pleasantly dry from the inside. Microfiber fabrics are very soft and light, and they have all the positive qualities that are valued in conventional synthetic materials: they are tear resistant, do not require special handling, etc.

care requirements. Microfiber items can be machine washed at 40°C on a delicate setting. When rinsing, emollients should not be used, otherwise the fabric will lose its water-repellent properties. Products cannot be wrung out and dried. Hang them up to dry. Ironing such fabrics is usually not required, but this can be done with a moderately heated iron on the “silk” setting.

Wool - common name for the wool of sheep, goats, camels, llamas, rabbits, dogs, etc. Wool varies in fineness and length of the fiber, in strength. Goat's hair is stronger than sheep's, camel's is stronger than goat's. Fineness is the most important quality parameter of wool fiber. The finer the hair, the softer, silkier and more delicate the yarn, the higher its quality. The general properties of wool include high thermal insulation, hygroscopicity, softness. The disadvantages of woolen yarn include its felting and the formation of pellets on it during friction. Moreover, the weaker the yarn is twisted, the stronger these shortcomings are manifested. In order to get rid of them, as well as to give the yarn other positive characteristics, such as strength and dimensional stability, artificial or vegetable fiber is added to wool yarn.

Wool mixture Semi-woolen yarn refers to threads with a wool content of 8 to 52%. The most common is a wool blend yarn with a content of about 35% wool, despite the fact that in fact this does not correspond to the name of the thread. That is why it is recommended to be more careful and take into account the composition of the yarn when choosing threads for knitting. Initially, wool mixture was produced from the remnants of yarn, woolen rags and other "waste" of production. However, this does not mean that such threads are of poor quality, on the contrary, they are simply made, as a rule, from regenerated wool in combination with high quality raw materials. At present, the situation has changed a little, now instead of natural wool, only artificial raw materials are used for the production of half-woolen yarn.

Acrylic- synthetic fiber, in many properties close to wool, resistant to light and other atmospheric agents, acids, weak alkalis, organic solvents. Acrylic fibers stain well; products made of yarn with acrylic “fall off” less, they are comfortable and warm, not prone to being eaten by moths. A yarn made from a mixture of acrylic and natural fibers combines best qualities natural fibers and synthetics - it is soft, warm, fluffy, and at the same time durable, the product "breathes", holds its shape well, does not shrink or stretch.

Acrylic- synthetic fiber, in many properties close to wool, resistant to light and other atmospheric agents, acids, weak alkalis, organic solvents. Acrylic fibers stain well; products made of yarn with acrylic “fall off” less, they are comfortable and warm, not prone to being eaten by moths. A yarn made from a mixture of acrylic and natural fibers combines best qualities natural fibers and synthetics - it is soft, warm, fluffy, and at the same time durable, the product "breathes", holds its shape well, does not shrink or stretch.

Alpacaor llama - an animal of the camel family. To alpaca wool, to a large extent, those qualities that seem to us in the definition of "camel hair" apply. Alpaca wool is highly valued. And therefore, and also due to its characteristics (wool is very hard), it is rarely used in its pure form. The benefits of alpaca wool are most pronounced in blended yarns. Blends with ordinary or merino wool are widely used, with artificial fibers(for example, with acrylic). Soft and delicate alpaca is not only an exquisite yarn, but also very warm.

Alpacaor llama - an animal of the camel family. To alpaca wool, to a large extent, those qualities that seem to us in the definition of "camel hair" apply. Alpaca wool is highly valued. And therefore, and also due to its characteristics (wool is very hard), it is rarely used in its pure form. The benefits of alpaca wool are most pronounced in blended yarns. Blends with ordinary or merino wool are widely used, with artificial fibers(for example, with acrylic). Soft and delicate alpaca is not only an exquisite yarn, but also very warm.

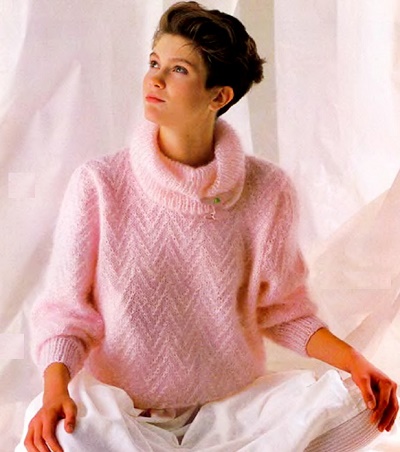

Produced from the down of Angora rabbits, it is very fluffy, soft and warm. In its pure form, angora is practically not used - it is expensive, and the fibers in the yarn do not hold well due to their softness and smoothness, the yarn sheds. But angora is just perfect when mixed with wool, merino wool or acrylic. The product is light, warm, delicate and pleasant to the touch. The most common yarn with 45-70% angora content. Interestingly, the higher this percentage, the worse the fluff keeps on the base, which means that the villi will constantly crumble from a product made from such threads. In addition, the greater the content of angora in the yarn, the more it falls off, so things made from such wool quickly wear out and lose their appearance.

When purchasing angora wool for knitting, it must be remembered that the finished product cannot actually be washed and it is undesirable to wet it, it can only be dry-cleaned, otherwise after the third wash the item will lose its original fluffy appearance. It is recommended to knit hats, mittens, scarves, sweaters from angora wool, they are very light and at the same time warm. Such threads are especially well suited for children's things, because kids, as a rule, do not like prickly blouses and mittens, and, on the contrary, they really like fluffy and soft products. The yarn with angora is very light, so for a size 42-44 product you need 200 - 250 g. Care instructions: careful hand wash with special detergents, you need to dry the product on a horizontal surface in a straightened state.

Bamboo. Bamboo fiber is a kind of viscose, but not from pine wood, but from bamboo. Bamboo fiber is softer than cotton and resembles silk in quality. It is very durable and has good wear resistance. In addition, bamboo fibers have a porous structure, due to which moisture is instantly absorbed by the canvas and evaporates. Knitted product made of bamboo yarn gives the body coolness and comfort in the hot summer. Bamboo cloth does not cause irritation and has natural antimicrobial properties, as it contains a component that prevents the growth of bacteria. Bamboo thread has a slight sheen, so it looks nobler than cotton. Bamboo yarn is produced both homogeneous in composition and mixed with cotton, polyamide, acrylic, wool.

Bamboo. Bamboo fiber is a kind of viscose, but not from pine wood, but from bamboo. Bamboo fiber is softer than cotton and resembles silk in quality. It is very durable and has good wear resistance. In addition, bamboo fibers have a porous structure, due to which moisture is instantly absorbed by the canvas and evaporates. Knitted product made of bamboo yarn gives the body coolness and comfort in the hot summer. Bamboo cloth does not cause irritation and has natural antimicrobial properties, as it contains a component that prevents the growth of bacteria. Bamboo thread has a slight sheen, so it looks nobler than cotton. Bamboo yarn is produced both homogeneous in composition and mixed with cotton, polyamide, acrylic, wool.

Viscose- soft, pleasant to the touch fiber with high color intensity and soft sheen. Viscose fiber is produced from liquid solutions of natural cellulose: from spruce, pine wood, stems of some plants, from cotton fiber processing waste. Yarn and threads made of viscose are called staple. Viscose has a composition close to natural cotton fiber, therefore, it is hygroscopic, breathable, pleasant to the touch. In addition, it gives a feeling of coolness in the heat. The viscose thread intended for knitting differs in softness, silkiness and is a little electrified. Unfortunately, viscose yarn also has disadvantages - due to the smoothness and low elasticity of the fibers, products often stretch quite strongly, especially after washing. For knitting in its pure form, viscose is not so common, it is usually used as part of a blended yarn, most often with cotton or nylon. Most often, these threads are used to knit clothes that can be worn, regardless of the season.

Viscose- soft, pleasant to the touch fiber with high color intensity and soft sheen. Viscose fiber is produced from liquid solutions of natural cellulose: from spruce, pine wood, stems of some plants, from cotton fiber processing waste. Yarn and threads made of viscose are called staple. Viscose has a composition close to natural cotton fiber, therefore, it is hygroscopic, breathable, pleasant to the touch. In addition, it gives a feeling of coolness in the heat. The viscose thread intended for knitting differs in softness, silkiness and is a little electrified. Unfortunately, viscose yarn also has disadvantages - due to the smoothness and low elasticity of the fibers, products often stretch quite strongly, especially after washing. For knitting in its pure form, viscose is not so common, it is usually used as part of a blended yarn, most often with cotton or nylon. Most often, these threads are used to knit clothes that can be worn, regardless of the season.

Camel's woolIt is produced from a downy undercoat, which is collected during the spring molt. Fiber fineness 17 - 21 mm, length 4 - 13 cm. Extra-quality fiber with a fineness of 17-18 microns is obtained from camel down. Camel hair can be light or dark with a brown tint that won't wash or shed, so it doesn't need to be dyed before knitting. In terms of quality, this wool can also be different, both coarse and soft, depending on the age of the camel from which it was sheared. Camel wool is known for its healing properties, lightness, hygroscopicity, hypoallergenicity, high level thermal insulation. Camel hair does not take color very well, but it has its soft colors in beige and brown. For knitting, yarn from 100% camel wool is used, as well as in mixtures with other types of fibers. There are two types of camels from which wool is sheared for the production of warm yarn: Bactrian and Vicuna. The wool of the Bactrian camel is less valuable because it is not entirely durable. Wicuna camels are bred in South America, from their wool they produce yarn of excellent quality - it is thin, durable and very warm.

Camel's woolIt is produced from a downy undercoat, which is collected during the spring molt. Fiber fineness 17 - 21 mm, length 4 - 13 cm. Extra-quality fiber with a fineness of 17-18 microns is obtained from camel down. Camel hair can be light or dark with a brown tint that won't wash or shed, so it doesn't need to be dyed before knitting. In terms of quality, this wool can also be different, both coarse and soft, depending on the age of the camel from which it was sheared. Camel wool is known for its healing properties, lightness, hygroscopicity, hypoallergenicity, high level thermal insulation. Camel hair does not take color very well, but it has its soft colors in beige and brown. For knitting, yarn from 100% camel wool is used, as well as in mixtures with other types of fibers. There are two types of camels from which wool is sheared for the production of warm yarn: Bactrian and Vicuna. The wool of the Bactrian camel is less valuable because it is not entirely durable. Wicuna camels are bred in South America, from their wool they produce yarn of excellent quality - it is thin, durable and very warm.

Cashmere- this is down (undercoat) of a mountain goat, fiber thickness 14 - 16 microns. These threads got their name from the place where they were first produced - Kashmir. Usually, to obtain this yarn, the hair of Tibetan alpine goats is used, which is not cut, but combed out. Currently, cashmere yarn is considered the most expensive of all other types. For knitting, threads with a 30% wool content are most often found. This figure is quite low, however, yarns with a lot of natural cashmere are not suitable for making knitwear, as they do not retain their shape and wear out very quickly. To keep cashmere yarn from rolling, it is mixed with wool fiber in different proportions. Cashmere yarn is pleasant to the touch, lays flat when knitting. The product from this yarn is warm, soft and cozy. Cashmere jumpers, coats and suits are much lighter than wool. This is due to the fact that down fibers are very thin and hollow inside.

Cashmere- this is down (undercoat) of a mountain goat, fiber thickness 14 - 16 microns. These threads got their name from the place where they were first produced - Kashmir. Usually, to obtain this yarn, the hair of Tibetan alpine goats is used, which is not cut, but combed out. Currently, cashmere yarn is considered the most expensive of all other types. For knitting, threads with a 30% wool content are most often found. This figure is quite low, however, yarns with a lot of natural cashmere are not suitable for making knitwear, as they do not retain their shape and wear out very quickly. To keep cashmere yarn from rolling, it is mixed with wool fiber in different proportions. Cashmere yarn is pleasant to the touch, lays flat when knitting. The product from this yarn is warm, soft and cozy. Cashmere jumpers, coats and suits are much lighter than wool. This is due to the fact that down fibers are very thin and hollow inside.

Lurex and metanit- a shiny thread, which is a thin strip of film, metallized or coated with foil. Lurex is added to the yarn to create a "metallic sheen" effect. It is never used on its own due to rigidity and fragility.

Lurex and metanit- a shiny thread, which is a thin strip of film, metallized or coated with foil. Lurex is added to the yarn to create a "metallic sheen" effect. It is never used on its own due to rigidity and fragility.

Silk . Natural silk is considered the most expensive raw material for knitting threads. It is a very thin fiber that has high strength. IN modern world very often, all types of shiny silky threads, such as viscose, acetate, nylon and other types, are called silk. Silk threads are distinguished by high elasticity, crease resistance, quickly absorb moisture, conduct heat poorly, they are soft and silky to the touch, and are well dyed in any tone. However, you need to know that the sun's rays and alkalis, which include water with powder or soap dissolved in it, destroy silk fibers, and products made from them lose their original appearance. Often silky threads, that is, those that are made from artificial raw materials, but look like natural silk, are used to make knitwear. Such things are quite practical and do not require special care.

Merino wool- wool with long and thin (16 - 17 microns) fibers, it is obtained from fine-fleeced merino sheep. It is sheared from the withers of animals, because it is in this place that it is especially even and soft, in addition, it is considered fine-fleeced, therefore more valuable . Merino wool is thin, light, durable, with a natural curl, which gives the yarn elasticity, and products - dimensional stability. It is also very elastic, because the coat is not perfectly even, it curls a little. best view such wool is considered Australian. 100% merino yarn is flawless, but very expensive. Merino yarn products are pleasant to wear because they do not irritate the skin. Children's things from such threads are very soft and warm. Merino wool is more expensive than regular wool, so other fibers are sometimes added to yarn to keep the price down. Natural wool, without any additives, is of excellent quality and durability. Despite this, merino wool products require special gentle care, since they can lose their shape and other important qualities from normal washing and drying.

Merino wool- wool with long and thin (16 - 17 microns) fibers, it is obtained from fine-fleeced merino sheep. It is sheared from the withers of animals, because it is in this place that it is especially even and soft, in addition, it is considered fine-fleeced, therefore more valuable . Merino wool is thin, light, durable, with a natural curl, which gives the yarn elasticity, and products - dimensional stability. It is also very elastic, because the coat is not perfectly even, it curls a little. best view such wool is considered Australian. 100% merino yarn is flawless, but very expensive. Merino yarn products are pleasant to wear because they do not irritate the skin. Children's things from such threads are very soft and warm. Merino wool is more expensive than regular wool, so other fibers are sometimes added to yarn to keep the price down. Natural wool, without any additives, is of excellent quality and durability. Despite this, merino wool products require special gentle care, since they can lose their shape and other important qualities from normal washing and drying.

Mohair (goat hair)- Angora goat wool is one of the warmest natural materials. High quality mohair is obtained from goats at the first shearing, the next level is mohair from two-year-old goats. These animals are bred in Spain, Asia Minor, South Africa and America. The wool of Angora goats is very long and thin, white in color with a silky sheen. One hundred percent mohair cannot be: it simply breaks up into separate fibers. To increase the strength of the thread, mohair is mixed with other fibers - acrylic or nylon. When mixed with nylon, mohair gains sheen and extra strength. Mohair yarn has long fluffy fibers, soft, airy, silky to the touch, elastic to tear. It is painted in bright, and at the same time natural colors. Mohair yarn is a thread with a maximum of 83% natural wool content. The fact is that modern technologies do not allow the production of yarn, which will include more wool, because goat hair is so difficult to spin that you have to use an artificial warp in order to make the thread strong. The most common yarn with a mohair content of 10, 20, 35, 40, 50 and 80%. Often any fluffy and soft yarn is called mohair, you can even come across the name “synthetic mohair”, but this is not true, real mohair is purely woolen. It is easy to wash and dye, unlike synthetics, but it is recommended to do this very carefully so as not to damage the fluff of which it consists.

Mohair (goat hair)- Angora goat wool is one of the warmest natural materials. High quality mohair is obtained from goats at the first shearing, the next level is mohair from two-year-old goats. These animals are bred in Spain, Asia Minor, South Africa and America. The wool of Angora goats is very long and thin, white in color with a silky sheen. One hundred percent mohair cannot be: it simply breaks up into separate fibers. To increase the strength of the thread, mohair is mixed with other fibers - acrylic or nylon. When mixed with nylon, mohair gains sheen and extra strength. Mohair yarn has long fluffy fibers, soft, airy, silky to the touch, elastic to tear. It is painted in bright, and at the same time natural colors. Mohair yarn is a thread with a maximum of 83% natural wool content. The fact is that modern technologies do not allow the production of yarn, which will include more wool, because goat hair is so difficult to spin that you have to use an artificial warp in order to make the thread strong. The most common yarn with a mohair content of 10, 20, 35, 40, 50 and 80%. Often any fluffy and soft yarn is called mohair, you can even come across the name “synthetic mohair”, but this is not true, real mohair is purely woolen. It is easy to wash and dye, unlike synthetics, but it is recommended to do this very carefully so as not to damage the fluff of which it consists.

Polyamide- polyamide fiber - characterized by high tensile strength, excellent wear resistance. Resistant to the action of many chemicals, well resists biochemical influences, stained with many dyes. Of particular value of these fibers and threads is their high dimensional stability - they do not lose their shape during wet and dry operation, they do not require special care. Disadvantages - high electrification, instability to light, low hygienic properties.

Polyamide- polyamide fiber - characterized by high tensile strength, excellent wear resistance. Resistant to the action of many chemicals, well resists biochemical influences, stained with many dyes. Of particular value of these fibers and threads is their high dimensional stability - they do not lose their shape during wet and dry operation, they do not require special care. Disadvantages - high electrification, instability to light, low hygienic properties.

Linen . Linen has been used for knitting clothes relatively recently, since linen has come into fashion, so a wide variety of such yarn has appeared. Many people think that linen threads are not suitable for making clothes, because it turns out to be impractical: it constantly wrinkles, has a noticeable weight and stiffness. However, linen yarn can be used for knitting summer things, best of all blouses, hats, and so on, since such threads pass air and moisture well, and it is not hot in clothes made from them.

Nylonused in the composition various kinds yarn to increase strength, wear resistance, reduce shrinkage after washing.

Lycra- this is an artificial elastic fiber that stretches well and easily restores its original shape without deforming. Thanks to such properties of this material, the quality of the threads and garments in which it is contained increases, such things do not wrinkle, do not hinder movements, and most importantly, they do not wear out for a long time. Knitwear made from yarn with the addition of lycra does not lose shape over time, elbows do not stretch out on them and wrinkles do not appear. When choosing yarn with a certain amount of lycra, it must be borne in mind that when steaming, such threads can shrink up to 50-70%. In order to avoid surprises, it is necessary to knit a sample before starting work and steam it with an iron, and only after that start knitting, taking into account the properties of the yarn.

Polyester- synthetic fiber from the group of polyesters. Clothing made of polyester microfibers is breathable, retains warmth, is soft and pleasant to the touch. This type of fiber is usually mixed with wool, cotton, linen and viscose, which gives the products increased wear resistance and elasticity while maintaining all positive qualities natural fibre. For knitting, both 100% polyester yarn and blends of polyester with other fibers are used.

Polyester- synthetic fiber from the group of polyesters. Clothing made of polyester microfibers is breathable, retains warmth, is soft and pleasant to the touch. This type of fiber is usually mixed with wool, cotton, linen and viscose, which gives the products increased wear resistance and elasticity while maintaining all positive qualities natural fibre. For knitting, both 100% polyester yarn and blends of polyester with other fibers are used.

Spandex- artificial elastic fiber made of polyurethane. Its remarkable properties enhance the quality of knitted tops and bottoms in which it is applied, giving them comfort. Spandex can be stretched to four to seven times its original length, and when the stretching force is removed, the fiber, like a spring, returns to its original state. Spandex is used only in small amounts in combination with other types of fibers, both natural and synthetic.

Spandex- artificial elastic fiber made of polyurethane. Its remarkable properties enhance the quality of knitted tops and bottoms in which it is applied, giving them comfort. Spandex can be stretched to four to seven times its original length, and when the stretching force is removed, the fiber, like a spring, returns to its original state. Spandex is used only in small amounts in combination with other types of fibers, both natural and synthetic.

Cottonis thin, short, soft, fluffy fibers. The fiber is somewhat twisted around its axis. Advantages: hygiene, durability, resistance to detergents, cotton is well breathable and absorbs moisture. In terms of strength, cotton yarn is inferior to linen or silk, but superior to wool. Cotton dyes well and practically does not fade, it is comfortable and pleasant to wear, soft, but durable, resistant to abrasion and tearing. Disadvantages: Wrinkles easily, tends to shrink, gets wet quickly and takes a long time to dry. Cotton yarn is dense, not elastic, it is recommended to knit with it not elastic bands and textured patterns, but openwork or a solid fabric.

Cottonis thin, short, soft, fluffy fibers. The fiber is somewhat twisted around its axis. Advantages: hygiene, durability, resistance to detergents, cotton is well breathable and absorbs moisture. In terms of strength, cotton yarn is inferior to linen or silk, but superior to wool. Cotton dyes well and practically does not fade, it is comfortable and pleasant to wear, soft, but durable, resistant to abrasion and tearing. Disadvantages: Wrinkles easily, tends to shrink, gets wet quickly and takes a long time to dry. Cotton yarn is dense, not elastic, it is recommended to knit with it not elastic bands and textured patterns, but openwork or a solid fabric.

fancy yarn- it is made from threads of different composition, color and quality or using special fiber production technologies, as a result of which the threads are obtained in the form of thin ribbons, woven, interconnected strands, and so on. Synthetic or metallic yarns are often mixed with natural yarns to make fancy yarns. The composition of this yarn percentage artificial and natural fibers - always indicated on the label of the skein. The fancy yarn is very well suited for making products with large patterns.

Synthetics. Synthetic fibers include lavsan, polypropylene, acrylic, nylon and many others. Synthetic yarn is characterized by high strength - on the one hand, and glassy luster, high electrification, instability to light, in which the threads can turn yellow and become stiff, brittleness after repeated washings - on the other hand. Artificial threads also do not stain well, so their color range is usually very limited. At the same time, artificial threads retain the shape of the product well, do not stretch or shrink if properly cared for. In addition, many synthetic fibers are highly elastic and resilient, so they can be used to make clothes that will not hinder movement. Synthetic fibers, for example, include acrylic, which is often called "artificial wool", because in its properties it really is very similar to natural threads. It works well with shiny yarns such as lurex, they can create a bright, matte or shimmery and iridescent sheen. Acrylic threads lend themselves well to dyeing in various tones. Products made from such threads practically do not “fall off”, do not sit down, they are light and warm. Very often on sale there are threads with the addition of acrylic, the percentage of its content in knitting yarn can range from 100 to 5%. From such threads you can knit beautiful warm and wearable things. Polyamide fiber is characterized by high tensile strength, excellent abrasion resistance. Such yarn resists biochemical attack well and is dyed with many dyes. The special value of the threads is that they do not lose their shape either wet or dry. However, the yarn is very exposed to sunlight and highly electrified.

Spectacular threads. Spectacular threads are called fibers that are used to give special kind yarn and products related to it. To obtain the effect of shine, for example, a special thread is used, which is called "Lurex". In addition to it, lamé, alunit, metlon, metanit, metallic, fertex and others can also be used. Some are made from metal foil, others are made from a chemical film coated with a special adhesive that gives the threads a shine. different colors. Such spectacular threads do not fade, do not fade when washed and worn in the sun. Very often, the yarn is sold already twisted with shiny threads, but you can also find them separately.

melange thread. The word "melange" is of French origin and in this case means a mixture, a combination of several threads of different colors. By resorting to this method, you can get a lot of interesting color combinations. For example, imitation of marble is achieved by mixing several shades of gray, and malachite is achieved by a combination of green and blue tones. From such yarn, you can knit both solid fabrics, and combinations of stripes and different geometric shapes. Melange wins compared to other types of yarn: irregularities and errors are not visible on such threads, therefore defective material is often used for melange. In addition, products made from melange yarn are suitable for all people, even very full ones, as it tends to visually hide figure flaws. To make it up, you need to choose the main color, and then decide on the rest of the tones using the selection method. Grey, pink and white go well together; black with green and brown; various shades of beige with white, in general, you can safely experiment with colors

Knitting and crocheting has always been a popular pastime for women. But today this type of needlework is experiencing a real boom. IN

The possibility of acquiring the most diverse in color, production and composition of yarn for knitting simply inspires anyone who decides to venture into the manufacture of any knitted product with their own hands. The choice of yarn is indeed quite large. For beginners and those who decide to refresh their memory about the types of yarn, we offer an overview of wool yarn.