Use of personal respiratory protection equipment. Gorbunov S.V., Ponomarev A.G. Means of individual and collective protection in emergency situations - file n1.doc

In particularly unfavorable conditions accompanying an emergency, it is recommended to use isolating agents individual protection(ISIZ). They completely protect the human respiratory organs from the ingress of harmful substances from the surrounding air into them and can be used when working in an atmosphere containing an insufficient amount of oxygen.

At the same time, the use of insulating gas masks also has some negative aspects - the body's heat transfer, mobility, vision, hearing, etc. are limited. Isolating RPEs are used by appropriately trained people (rescuers) who have the skills to work in such equipment and have high functional reserves of the body.

Self-contained isolating gas masks

When liquidating emergencies, rescuers use insulating regenerative gas masks IP-4M, IP-5, IP-6.

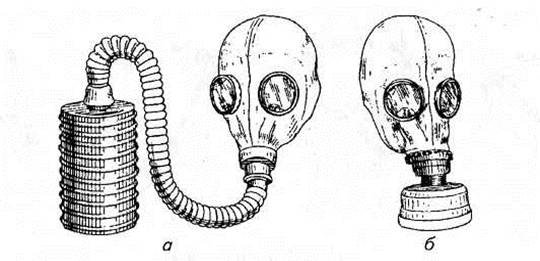

Isolating gas mask IP-4M(Fig. 15, a) consists of a front part with a connecting tube, a regenerative cartridge with a starting briquette, a breathing bag and a frame. The set also includes anti-fog films, insulated cuffs and a bag.

The principle of operation of an insulating gas mask is to release oxygen from chemical substances when absorbing carbon dioxide and moisture exhaled by a person.

The operating time in IP-4M is determined by physical activity and is about 180 minutes with light physical activity, 60 minutes with medium physical activity, and 30 minutes with heavy exercise. The working temperature range is from -40 to +40 ºС.

Rice. 15. Isolating gas masks IP-4M (a) and IP-5 (b).

The faceplate is available in four sizes. The selection of the face part in size is similar to the GP-7 gas mask.

Isolating gas mask IP-5(Fig. 15, b) in addition to work in the contaminated area, it can also be used to get out of flooded (sunken) objects by the method of free ascent or by the method of gradual ascent to the water surface, and also allows you to perform light work under water at a depth of 7 m. Time work depending on physical activity - from 75 to 200 minutes.

The procedure for using an insulating gas mask. The transfer of the IP-4 (IP-5) apparatus to the "combat" position is carried out, as a rule, in an atmosphere suitable for breathing.

To transfer the device to the "combat" position when it is located on its side or behind the back, it is necessary:

- open the lid of the bag and take out the front part;

- throw the front part over the left shoulder to the chest (when located behind the back);

- remove the plug from the front end pipe and put it in the bag;

- take off the headdress;

- take a deep breath and put on the front part so that there are no folds and distortions, and the spectacle knot is against the eyes;

- exhale and activate the starting device, for which pull out the safety pin and screw in the screw clockwise until it stops;

- make sure that the starting briquette is activated;

- put on a hat;

- close the lid of the bag and fasten it with buttons.

Signs of triggering the briquette are: entry into the mask space of a warm gas mixture; filling the breathing bag with a gas mixture and etching the gas mixture through an overpressure valve; warming up the front cover of the cartridge (at positive temperatures). It is prohibited to use the apparatus in which the starting pellet has not worked.

Signs of the end of the regenerative cartridge are: the impossibility of taking a full breath while performing work, feeling unwell (headache, dizziness, nausea, etc.). It is not recommended to work in a gas mask until the regenerative cartridge has been fully exhausted. Replacement of the spent regenerative cartridge in an atmosphere contaminated or unfit for breathing is only permitted in exceptional cases.

The duration of the permissible continuous stay in insulating gas masks with the change of regenerative cartridges is 8 hours. Repeated stay in them is allowed after 12 hours of rest.

Characteristics of some RPE

The time of protective action is given for an air flow rate of 30 l / min, a relative air humidity of 75% and an ambient temperature of -30 ° C to 40 ° C. According to other SDYAV, the GP-7 kit can provide protection for an average of 30-60 minutes ...

To protect rescuers from SDYAV in case of accidents at enterprises, filtering industrial gas masks of large and small dimensions can also be used. They have a strict targeting (selectivity) and are designed to absorb only specific chemicals.

Boxes of industrial gas masks are produced with an anti-aerosol filter (PAF) and without it (brands M and CO). To absorb SDYAV, it is advisable to use boxes with PAF. The time of protective action of boxes of large dimensions for some SDYAV is given in the table:

Characteristics of boxes of industrial gas masks according to SDYAV

| nameСДЯВ | initial concentrate mg / m 3 | time of protective action of boxes, mini identification coloring | ||||||||||||

| A brown. | Into the yellow | CD gray | SB white | M red | BKF green | |||||||||

| Ammonia | - | 2,2 | 2,6 | |||||||||||

| Acrylonitrile | - | - | ||||||||||||

| Chlorine | 37,6 | |||||||||||||

| Sulfurous anhydrite | - | 11,9 | - | - | - | - | ||||||||

| Ethylene oxide | - | |||||||||||||

| Nitrogen oxides | - | - | - | |||||||||||

| Phosgene | ||||||||||||||

| Hydrogen fluoride | - | |||||||||||||

| Cyanogen chloride | - | - | - | - | - | |||||||||

| Chloropicrin | - | - | - | - | - | |||||||||

| Carbon disulfide | 50,7 | 56,9 | 49,7 | |||||||||||

Gas mask boxes with PAF, in addition to the characteristic color, have a vertical white stripe. Industrial gas masks with small-sized boxes can be used at SDYAV concentrations that are 2.5 times lower than the values indicated in the previous table.

The industrial filtering gas mask PFM-1 is designed to protect against vapors, gases, aerosols only of a specific SDYAV. The gas mask consists of a front part with panoramic glass, a gas mask box of a certain brand (depending on the type of SDYAV). It is used at a distance of 500 m or more from the source of infection. Working time in a gas mask - from 30 to 100 minutes (with an average load of 30 l / min).

Insulating RPE

To protect rescuers from high concentrations of SDYAV vapors, as well as in conditions of a high smoke-filled atmosphere after fires, explosions and ignition of substances, insulating RPE are used. They are used when the composition and concentration of substances are unknown; when the content of free oxygen in the air is less than 16% (volume fraction); when the time of the protective action of other RPE is not enough to perform tasks in the contaminated zone.

Isolating RPEs are subdivided into autonomous and hose-type ones.

Autonomous RPE provide a person with a breathing mixture from cylinders (with compressed air or oxygen) or with the help of oxygen-containing products due to the regeneration of exhaled air.

When eliminating the consequences of accidents associated with the release (spill) of SDYAV, the main means to ensure the protection of rescuers are autonomous RPE. They include breathing apparatus, self-contained gas masks, self-rescuers. Breathing apparatuses are equipped with metal cylinders with a supply of compressed air (oxygen) and valves to regulate its supply to the respiratory system.

V hose-type RPE clean air is supplied to the respiratory system through a hose from blowers or compressors.

Insulating gas masks are equipped with regenerative cartridges, in which oxygen is in a granular product (over-peroxides of alkali metals - sodium and potassium) and is released during the absorption reaction of carbon dioxide and water vapor exhaled by a person. The following breathing apparatus and insulating gas masks can be used to conduct rescue operations in the focus of the SDYAV lesion: ASV-2 (on compressed air), KIP-8, KIP-9 (on compressed oxygen) and IP-4 (on chemically bound oxygen).

The self-contained breathing apparatus ASV-2 is designed to protect the respiratory organs in an atmosphere of high concentrations of SDYAV. It consists of a face-piece such as a mask, a system of hoses supplying air from cylinders to the respiratory system, cylinders (2 pcs.) With a shut-off valve, a reducer, a pressure gauge, a lung valve for turning off and turning on excess pressure. Air volume 1600 l, weight 16.4 kg, operating temperature range - from - 40 ° С to 40 ° С, protective action time at an average load of 30 l / min - 45 minutes.

The self-contained breathing apparatus KIP-8 (KIP-9) is designed to protect the respiratory system in an atmosphere of high concentrations of SDYAV. It consists of an MIP-1 face mask, oxygen cylinders, a signaling device showing the remaining operating time. Oxygen reserve 200 l, weight 10 kg, protective action time at average load 120 minutes. The IP-4M insulating gas mask is designed to protect the respiratory system from harmful impurities of high concentrations of SDYAV, as well as to protect in conditions of a lack or absence of oxygen. It consists of a front part (MIA-1 mask) with a connecting tube, a breathing bag with an overpressure valve, a speech membrane and insulation cuffs. Weight 3.4 kg, temperature of inhaled air up to 50 ° C, protective action time for light, medium and heavy loads is 180, 75 and 40 minutes, respectively, breathing bag, bag and connecting tubes are made of special fabric resistant to aggressive liquids.

The industrial insulating self-rescuer SPI-20 (PDU-3) is designed for emergency short-term protection and exit from the contamination zone. It consists of a hood with sealing around the neck (SPI-20), a face-piece in the form of a mask (PDU-3), a regenerative cartridge, and a breathing bag with an overpressure valve. Weight of SPI-20 - 2.2 kg, PDU-3 - 1.6 kg, temperature range of use of SPI-20 - from 0 ° С to 60 ° С, PDU-3 - from -30 ° С to 40 ° С, time protective action at light load - 45 minutes, at medium load - 20 minutes.

Self-contained breathing apparatus are reusable devices with the ability to repeatedly replace cylinders or regenerative cartridges. The time of work in an insulating RPE is mainly determined by physical activity, ambient temperature and the supply of air (oxygen) or oxygen-containing substances. Physical activity and the supply of air (oxygen) or oxygen-containing substances are the main characteristics that determine the indicator of the time of protective action of breathing apparatus (gas masks) during continuous operation in them. One of the important elements of respiratory protection is the knowledge and ability to properly use PPE, including gas masks.

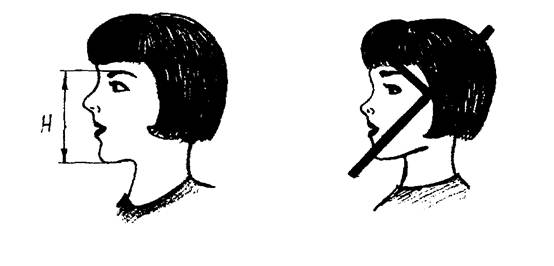

Preparing a gas mask for use begins with determining the required size of the helmet-mask. It is set according to the size of the vertical girth of the head by measuring it along a closed line passing through the crown, chin and cheeks. Measurements are rounded to 0.5 cm.When measuring up to 63 cm, take the zero size, from 63.5 to 65.5 cm - the first, from 66 to 68 cm - the second, from 68.5 to 70.5 cm - the third, from 71 cm and more - the fourth. Before use, the gas mask must be checked for serviceability and tightness. When examining the helmet-mask, you should make sure that its height corresponds to the required one. Then determine its integrity by paying attention to the glass. After that, check the valve box, the condition of the valves. They should not be warped, clogged or torn. The filter-absorbing box should be free of dents, rust, punctures, or damage in the neck. It is also necessary to pay attention to the fact that grains of the absorber are not sprinkled in the box.

The gas mask is assembled as follows. V left hand take the helmet-mask by the valve box. Right hand screw the filtering-absorbing box with the neck into the branch pipe of the valve box of the helmet-mask. Before putting on the new front part of the gas mask, wipe the outside and inside with a clean cloth slightly moistened with water, and blow out the exhalation valve. If any damage is found in the gas mask, they are eliminated, and if this is not possible, then the gas mask is replaced with a serviceable one. The tested gas mask in assembled form is placed in a bag: downwards - a filtering-absorbing box, on top - a helmet-mask, which is not bent, but only slightly tucked up the head and side parts so as to protect the glass.

The gas mask is worn enclosed in a bag. The shoulder strap is thrown over the right shoulder. The bag itself is on the left side, with the flap away from you. The gas mask can be in the following positions: "marching", "ready", "combat". In "marching" - when there is no threat of contamination with toxic substances, SDYAV, radioactive dust, bacteriological agents. Bag on the left side. When walking, it can be slightly shifted back so that it does not interfere with the movement of the hands. The top of the bag should be at waist level, the flap should be closed. In the "ready" position, the bag must be secured with a belt tape, slightly pushing it forward, unfasten the valve so that you can quickly use the gas mask.

When transferring a gas mask to a "combat" position, you must:

Hold your breath, close your eyes;

Take off the hat and pinch it between your knees or put it next to it;

Remove the helmet-mask from the bag, take it with both hands by the thickened edges at the bottom so that the thumbs are on the outside, and the rest are on the inside. Bring the helmet-mask to the chin and with a sharp movement of the hands up and back, pull it over the head so that there are no folds, and the glasses fall against the eyes;

Exhale fully, open your eyes and resume breathing;

Put on a hat, button up the bag and fasten it to the torso, if this has not been done before.

A gas mask is considered to be worn correctly if the glasses of the front part of the glasses are against the eyes, and the helmet-mask fits snugly to the face. The need to exhale strongly before opening the eyes and resuming breathing after putting on the gas mask is explained by the fact that it is necessary to remove the contaminated air from under the helmet-mask if it got there at the time of putting it on. When wearing a gas mask, breathe deeply and evenly. No need to make sudden movements unnecessarily. If there is a need to run, then you should start jogging, gradually increasing the pace. To remove the gas mask, you need to lift the hat with one hand, with the other grab the valve box, slightly pull the helmet-mask down and remove it with a forward and upward movement; put on a hat, turn out the helmet-mask, wipe it thoroughly and put it in a bag. When using a gas mask in winter, coarsening (hardening) of rubber, freezing of glasses, freezing of the petals of the exhalation valves or freezing them to the valve box is possible. To prevent and eliminate these malfunctions, it is necessary to periodically heat the face of the gas mask while in a non-contaminated atmosphere by placing it under clothing. If, before putting on, the helmet-mask is still frozen, then you should slightly knead it and, putting it on, warm it up with your hands until it fully adheres to the face. When wearing a gas mask, prevent freezing of the exhalation valves by heating the valve box with your hands from time to time, while blowing (with a sharp exhalation) the exhalation valves.

Respiratory protection equipment(RPE) - worn on a person technical device providing respiratory protection from occupational risk factors (GOST R 12.4.233-2012, p. 2.99). The general name for respirators and gas masks used when working in a polluted atmosphere and / or in an oxygen-deficient atmosphere. Air jackets and air suits used in the nuclear industry can also be referred to the RPE. RPEs are the latest, and at the same time - the most unreliable means of protection.

Collegiate YouTube

-

1 / 5

To prevent contaminated air from entering the respiratory system, the RPE must separate them from the surrounding polluted atmosphere (for this, front part), and provide the employee with clean or purified air suitable for breathing (filters are used for this, or a source of clean air: external - with supply through a hose, or autonomous - supply in cylinders, in a chemically bound form, etc.). The type of RPE and its protective properties depend on the design of its components and the principle of operation (see Respiratory Personal Protective Equipment Classification).

Front part

The front part of the RPE is the part of the RPE that connects Airways the user with other parts of the device and separating the respiratory tract from the surrounding atmosphere. The face part can be either tight-fitting (for example, mask, half-mask, quarter-mask) or loose (for example, helmet, hood).

Facials that fit tightly to the face

Mouthpiece- the front part of the RPE, held by teeth or teeth and a headband, tightly compressed by the lips and through which air is inhaled and exhaled, while closing the nose with a clip. For a more secure fit, it can be equipped with a chin rest. It is mainly used in self-rescuers.

Quarter mask covers the mouth and nose, but does not cover the chin. In the USSR, quarter-masks were not made, and in the Russian Federation they did not receive distribution.

Half mask covers the mouth, nose and chin. Can be made of filter material (filter half mask) or airtight elastomer material (elastomer half mask). Elastomeric half masks are made with removable gas mask, anti-aerosol or combined filters, or they are connected to a source of clean air. Elastomeric half masks with non-removable filters (disposable) are also produced, but they have not become widespread in the Russian Federation.

Full face mask covers the mouth, nose, chin and eyes, is used with replaceable filters, or connected to a source of clean air.

- Due to the tight fit, these face pieces can be used in inexpensive RPEs that do not have a forced supply of breathable air under the mask, since they are able to prevent ambient air from entering the respiratory system during inhalation. And when these face pieces are used in conjunction with a pressurized source of breathable air under the mask, their protective properties are greatly enhanced.

Facials with a loose fit to the face

Air Hood- The face part of the RPE, which is freely worn on the head, which completely covers the head, is usually made of impermeable fabric.

Pneumatic helmet- the front part (hard), which covers the face and head, and additionally provides protection of the head from mechanical stress.

Pneumatic jacket- the front part, consisting of a hood and jacket, made of impervious materials.

Pneumosuit- the front part, made of impermeable material, and completely covering the whole body. Air jackets and air suits provide the most reliable protection for employees, and are used mainly in the nuclear industry (when clean air is supplied through a hose).

- All of these face pieces can only be used when they are forcedly supplied with air (pressurized, continuously, or on demand while inhaling). For air supply, autonomous sources (filter purification units, cylinders, etc.) can be used, or remote ones - with supply through a hose.

Breathable air source

Application of RPE in industry

With the correct choice of RPE, its effectiveness in practical use depends very much on how correctly the face piece is matched to the face of a particular worker (if there is a discrepancy in shape and size between the mask and the face, gaps arise through which polluted air can enter the respiratory system), and on how correctly the RPE is used. Therefore, in developed countries, where both the employer and the PPE manufacturer are liable in the event of injury to the worker, the use of PPE takes place within the framework of a (written) respiratory protection program, is regulated in detail by legislation and - in accordance with the requirements of this legislation - is checked by inspectors (planned, and on employee complaints). Respiratory protection standards have been used to regulate the choice and organization of the use of respiratory protective equipment in developed countries for several decades (see Legislative regulation of the selection and organization of respirator use, and to verify compliance with the requirements - specific instructions for conducting inspections for inspectors.

The relationship between health preservation, the quality of RPE and the organization of their use

In developed countries, there are also standards for the certification of the RPEs themselves - as separate devices. These standards are intended to additions respiratory protection standards by ensuring a certain minimum level of product quality. For example:

The standard for the certification of half-mask respirators contains certain requirements for its quality, the fulfillment of which allows, with the right choice and correct application, to reliably ensure a 10-fold reduction in the contamination of the inhaled air (USA). On the other hand, the standard for the selection and use of respirators requires that the selection of a half mask should not be used when the air pollution exceeds 10 MPC, that only certified half masks are purchased, and that the employer takes a number of specific measures to ensure the correct individual selection and correct use of half masks by trained workers.

The standards for the certification of gas filters contain specific requirements for protective properties filters different types when exposed to several specific harmful gases - under strictly defined conditions. However, the conditions for using these same filters may differ from laboratory (for certification), and the filter life can also be very different from that required for successful certification. In addition, the amount of harmful substances for protection against which gas filters are used is hundreds of times greater than the amount of gases used for certification, and the service life of a gas filter can greatly depend on the type of harmful gases, or their combination. Therefore, for the timely replacement of gas filters, legislation obliges the employer to use filters with end-of-life indicators, or to replace filters on a schedule, using the results of life calculations made using special computer programs or other methods.

- The combination of meeting the requirements for the quality of RPE and meeting the requirements for their correct selection and organization of the correct use allows to ensure sufficiently reliable health protection, and to avoid the occurrence of occupational diseases and the death of workers. This was confirmed by numerous measurements of the protective properties of various types of RPEs, which were carried out directly during work in various industrial conditions (see Tests of respirators in industrial conditions), as well as when simulating work performance (in a laboratory) and calculations made on the basis of statistical processing of measurement results ...

Conclusion

The correct use of RPE is highly dependent on the behavior of the individual worker, and even when used correctly, it is not stable (see Respirator). Therefore, the legislation requires the employer to use the RPE to preserve the health of workers only when it is impossible to provide acceptable working conditions by other, more reliable methods - changing the technological process, sealing equipment, automating production, using local and general ventilation, etc. In addition, harmful substances that pollute the air can enter the body not only through breathing, but also with insufficient adherence to the rules of personal hygiene (food, drink, etc.). The RPE cannot prevent the ingress of harmful substances into the body in such ways, and this also makes the reduction of air pollution more preferable.

Notes (edit)

- UK, British Standard BS 4275: 1997 "Guide to implementing an effective respiratory protective device program":

If the air in the workplace is contaminated, it is important to determine whether it is possible to reduce (to an acceptable level) the risk posed by this contamination, with the help of technical means and organizational measures- not using respirators. ... If the identified risk is unacceptable, then the methods specified in paragraphs ( a)-(with) to prevent and in paragraphs ( d)-(k) for risk reduction, not respiratory protection. ...

a) Using other substances that are less toxic. b) The use of the same substances in a less dangerous form, for example, replacing a fine powder with a coarse one, or granules, or a solution. c) Replacing the technological process with another - so that dust formation is reduced. d) Execution of the technological process and material handling in fully or partially sealed equipment. e) Construction of shelters in combination with local ventilation suction. f) Local exhaust ventilation - local suction (no shelters). g) Use of general ventilation. h) Reducing the duration of exposure periods. i) Organization of work in such a way as to reduce the ingress of contaminants into the air, for example - closing unused containers. j) The use of measuring equipment and associated alarms to warn people about exceeding the permissible level of air pollution. k) Effective cleaning. l) Performing a respiratory protection program. Since in many cases the risk of contaminated air being inhaled by workers cannot be reduced by just one method, all steps a) to l) that are designed to reduce air pollution or to reduce the risk of inhaling contaminated air must be carefully studied. But when using a combination of two or more methods, you can reduce the risk to an acceptable level. The requirements of this standard must be met during the entire time, while the reduction of the risk of inhalation of contaminated air is being developed and carried out using all reasonable technical and organizational measures (without the use of RPE), and after such a reduction is completed. ... If the implementation of risk reduction measures does not allow for a safe and healthy working environment, an assessment of the residual risk of inhalation of contaminated air or absorption of harmful substances through the skin should be made. This will determine what (type) respirators are needed and what the respiratory protection program should be.USA, 29 CFR 1910.134 "Respiratory Protection", translation available: PDF

1910.134 (a) (1) The main way to prevent those occupational diseases that arise from the inhalation of air contaminated with dust, mist, smoke, smog, harmful gases and aerosols should be to prevent human exposure to harmful substances and to prevent air pollution. For this, it is necessary (as far as possible) to automate and mechanize production, change the materials used and technological process, use technical means, for example - to seal production equipment and use ventilation equipment. In cases where these methods are not effective enough, or during their installation and repair, you should use reliable and effective respirators.

Germany, DIN EN 529: 2006 "Atemschutzgeräte - Empfehlungen für Auswahl, Einsatz, Pflege und Instandhaltung - Leitfaden"

Workers' exposure to hazardous substances must be eliminated (reduced to a safe level). If this is impossible, or difficult to implement, then it should be reduced to a minimum at the source through the use of technical, organizational and other measures - before respirators are used.

... RPEs should only be used when one or more of the following conditions are met: a) Other means were used, but they were not enough; b) The impact exceeds the maximum permissible, and the means of (collective and technical) protection are still being established; c) Workers have to work in near-disaster conditions as work cannot be postponed until the impact is mitigated at the source by other means. d) Workers are rarely and briefly exposed to more than the exposure limit, so other protection methods are impractical; e) A self-rescuer is required for self-evacuation in the event of an emergency; f) Execution of emergency work by rescuers.

Literature

Link to list of standards

Tutorials

- N. Ivonin. Filtering and insulating protogas. - Leningrad department of the publishing house of the NKO of the USSR. - Moscow, Leningrad: Lengorlit, 1935 .-- 146 p. - 15,000 copies. PDF

- M. Dubinin and K. Chmutov. Physicochemical foundations of the gas mask business. - Military Academy of Chemical Defense of the RKKA named after Voroshilov. - Moscow, 1939 .-- 292 p. - 3000 copies.

- Nancy J. Bollinger, Robert H. Schutz et al. NIOSH Guide to Industrial Respiratory Protection. - NIOSH. - Cincinnati, Ohio: National Institute for Occupational Safety and Health, 1987 .-- 305 p. - (DHHS (NIOSH) Publication # 87-116). Translated (2014): Guide to Respiratory Protection in Industry PDF Wiki

- Linda Rosenstock et al. TB Respiratory Protection Program In Health Care Facilities - Administrator "s Guide. - Cincinnati, Ohio: National Institute for Occupational Safety and Health, 1999. - 120 pp. - (DHHS (NIOSH) Publication No. 99-143). There is a translation: Guidelines for the use of respirators in healthcare facilities for the prevention of tuberculosis PDF Wiki.

- Nancy Bollinger. NIOSH Respirator Selection Logic. - NIOSH. - Cincinnati, OH: National Institute for Occupational Safety and Health, 2004 .-- 32 p. - (DHHS (NIOSH) Publication No. 2005-100). Translated: Respirator Selection Guide PDF Wiki

- Guidelines for the selection and management of respirators (UK), on English language The Health and Safety Executive. Respiratory protective equipment at work. A practical guide. - 4. - Crown, 2013 .-- 59 p. - (HSG53). - ISBN 978 0 7176 6454 2.

- Guidelines for the selection and organization of the use of respirators (FRG), in German BGR / GUV-R 190 Benutzung von Atemschutzgeräten. - Deutsche Gesetzliche Unfallversicherung e.V. (DGUV). - Berlin: Deutsche Gesetzliche Unfallversicherung e.V. (DGUV), Medienproduktion, 2011 .-- 174 p.

- Canadian Guidelines for the Use of RPE, in French: Lara, Jaime; Vennes, Mireille. Guide pratique de protection respiratoire. - Commission de la santé et de la sécurité du travail du Québec. - Montréal, 2002 .-- 55 p. - ISBN 2-550-37465-7.

- Occupational Safety and Health Administration (OSHA) Training Video Series - in English

- Video recording of half-masks testing, clearly showing their low insulating properties: at Wikimedia Commons ; from YouTube

Respiratory Personal Protective Equipment Books

- Description of gas masks and bandages available in the active armies in 1915 djvu

- Chukaev K.I. Poisonous gases 1915 djvu

- BF Grinder What everyone needs to know in a respirator 1916 djvu

- I.G.Korits Suffocating and Poisonous Gases 1916 djvu

- V.N.Boldyrev Brief practical instruction for fumigating troops Moscow 1917 djvu

- A.S.Shafranova What you need to know about respirators 1930

- Grindler B. F. What everyone needs to know in respirators 1932 djvu

- M. Mitnitsky Wearing gas masks at the production of M 1937 djvu

- Vigdorchik E. A. "Instructions for the use of industrial gas masks" Leningrad 1938 (project)

Figure 5

The use of respiratory PPE is effective way improving working conditions at long-distance non-stationary workplaces, where the installation of ventilation systems is impossible. Respiratory protection equipment (RPE) includes respirators, half masks and masks with replaceable filters, gas masks. All of them are divided into two large classes: filtering and insulating.

Respiratory protection filtering means easy to operate and provide effective cleaning of human-inhaled air, which is why they are widely used in industry. The main conditions for the use of filtering RPEs are the use under conditions of a known composition and concentration of harmful substances in the air of the working area and the obligatory presence of a sufficient amount of oxygen in the air (at least 17%).

Depending on the state of aggregation of harmful substances from which protection is required, filtering RPEs are divided into three classes for their intended purpose: anti-aerosol; gas mask; gas and aerosol (combined).

Anti-aerosol (anti-dust) filtering respiratory protection... This class of filtering RPE is designed to protect the human respiratory system from harmful substances in the air in an aerosol aggregate state (dust, smoke, fog). Air purification in them is based on the use of high-performance filter materials and ultra-fine fibers.

Respiratory gas filtering equipment... This class of filtering RPE is designed to protect the human respiratory system from gases and vapors of harmful substances. Air purification in them is based on the use of specific catalysts and absorbers of harmful gases and vapors in the construction of respiratory protection equipment, depending on the presence of which the purpose of filters is determined. Gas and aerosol filtering respiratory protection. This class of filtering RPE is designed to protect the human respiratory system from aerosols, gases and vapors of harmful substances when they are simultaneously or separately present in the air of the working area. Air purification in them is based on the joint use in the design of aerosol and gas filters.

Respiratory Personal Protective Equipment... Their principle of operation is based on isolating the human respiratory system from the external environment and providing breathing air from a source of the respiratory mixture, or from a clean zone through a hose. Isolating respiratory protection is used in cases of insufficient oxygen content, unknown composition of harmful substances in the air of the working area, as well as in cases where the concentration or toxicity of harmful substances does not allow the use of filtering respiratory protection can be used regardless of the composition of the surrounding air. However, of these, only hose-type RPEs, which are distinguished by relative simplicity and reliability in operation, have become widespread when performing technological operations. The disadvantages of hose-type personal respiratory protection are the limitation of the user's movement and the resistance to breathing of the person. Therefore, when performing certain types of work (when working inside a tank boiler, etc.), it is necessary to use a RPE with forced (active) air supply. In this case, certain requirements are established for air pressure, volume of supplied air and its temperature.

Personal respiratory protection or RPE are specially designed technical devices that provide respiratory protection from a harmful, aggressive environment. RPE is a technical device worn on a person that protects the respiratory system from occupational risk factors (GOST R 12.4.233-2012, p. 2.99).

If the technological process is accompanied by the release of a large amount of harmful or toxic substances (aerosols, vapors, gases) and it is impossible to reduce their concentration to the MPC level by sanitary and hygienic or technical measures, then personal respiratory protection means are used, which are subdivided into filtering and isolating RPEs.

Respiratory personal protective equipment (RPE) is designed to protect against inhalation and ingestion of harmful substances (aerosols, gases, vapors) and / or a lack of oxygen (oxygen content in the air is less than 18%). In accordance with GOST R 12.4.034-2001 "SSBT. Personal respiratory protection.

Classification and labeling "there are two different methods of providing personal respiratory protection from exposure to ambient air:

Air purification (filtering RPE);

Supply of clean air or breathing mixture based on oxygen from any source (isolating RPE).

Filtering RPEs supply the working zone air purified from impurities into the breathing zone, insulating - air from a clean space located outside the working zone or from special containers.

Filtering protective equipment ("SSBT. Filtering personal respiratory protection. General technical requirements») Are industrial gas masks with filter boxes of various brands and filter respirators. Filtering protective equipment according to its intended purpose are divided into anti-aerosol for protection against dust, anti-gas, for protection against gases and vapors, and anti-gas and aerosol, protecting against gases, vapors and dust while their presence in the air.

To protect the respiratory system from aerosols (dust), dust masks and respirators are used. If, in addition to aerosols, harmful vapors and gases are present in the air, use universal or gas masks and gas masks. Anti-dust respirators protect against aerosols at concentrations up to 200 MPC, and anti-gas and universal respirators - at concentrations of vapors and gases up to 15 MPC. Gas masks effectively protect the respiratory organs at concentrations of vapors and gases up to 0.5% by volume.

The main criteria for evaluating the RPE are: the tightness of the mask, the tightness of the outlet valves, the hose, the degree of air purification, breathing resistance, ease of use and storage, the possibility of long-term use, aesthetic qualities.

Air jackets and air suits used in the nuclear industry can also be referred to the RPE.

RPE are divided into two groups: filtering and insulating.

Respiratory personal protective equipment is divided into two types:

- Respiratory protection means of filtering action- these are gas masks and respirators. In filtering devices of this class, air from the environment passes through a set of filters, after which it is supplied to the respiratory system. The simplest version of a filter breathing apparatus is a gauze bandage (respirator). The most famous is the gas mask. In accordance with GOST, filtering RPEs are designated by the letter F.

- Respiratory personal protective equipment of insulating type are able to provide the human respiratory organs with the necessary amount of fresh air, regardless of the composition of the surrounding atmosphere. These include: self-contained breathing apparatus that provide the respiratory organs of a person with a respiratory mixture from cylinders with compressed air or compressed oxygen, or by regenerating oxygen using oxygen-containing products; hose breathing apparatus, with the help of which clean air is supplied to the respiratory organs through a hose from blowers or compressor lines.

Unlike filter breathing apparatus, self-contained breathing apparatus is not connected with the atmosphere, since they have their own supply of oxygen or air. Due to this, in such breathing apparatus it is possible to carry out work in an oxygen-free atmosphere (for example, at the site of a fire) or in liquid media (water). Devices of this type are divided into two classes:

- Open cycle. In this case, the expiratory products are discharged into the atmosphere.

- Closed loop. Carbon dioxide released during breathing is absorbed by the chemical composition, enriched with oxygen and supplied for inhalation (Rebreather). The possible operating time in such equipment is several times longer than in open-circuit devices. However, such devices are more difficult to maintain and operate.

Classification of RPE

A breathing apparatus is a complex device that protects the respiratory system from an aggressive external environment, delivers purified air for inhalation and removes expiratory products.

The harmful effects include: solid aerosols (dust), gases, liquid aerosols (when spraying), condensation aerosols (occurring when the metal is heated) and vapors. This division refers specifically to harmful suspended solids in the air that act by inhalation. When choosing personal protective equipment for the respiratory system, it is necessary to be guided by some indicators: the level of environmental pollution and the composition of the pollution, and taking into account these data, it is possible to determine the device necessary for protection. Respiratory protection means include respirators, half masks, gas masks. Respirators are a lightweight version of protection and are used in gentle conditions, but their effectiveness is not reduced by this. There are different types of respirators.

The RPE includes gas masks, respirators, self-contained breathing apparatus, a set additional cartridge, hopcolite patron.

According to the principle of protective action, RPEs are subdivided into filtering and insulating.

Respiratory protection equipment: RPE filtering actions are gas masks and respirators. They are widely used as the most affordable, simple and reliable in operation. In accordance with GOST filtering RPEs are designated by the letter "F"

RPE isolating type are able to provide the respiratory organs of a person with the necessary amount of fresh air, regardless of the composition of the surrounding atmosphere.

These include:

- self-contained breathing apparatus that provide the respiratory organs of a person with a breathing mixture from cylinders with compressed air or compressed oxygen, or by regenerating oxygen with the help of oxygen-containing products;

- hose breathing apparatus, with the help of which clean air is supplied to the respiratory organs through a hose from blowers or compressor lines.

In accordance with GOST, insulating respiratory protective equipment is designated by the letter "I".

Respirators.

Respirators are lightweight respiratory protection against harmful gases, vapors, aerosols and dust. They are widely used in mines, mines, chemically harmful and dusty enterprises, when working with fertilizers and pesticides in agriculture. They are used at nuclear power plants, scale at metallurgical enterprises, during painting, loading, unloading operations.

Purification of the inhaled air from harmful impurities is carried out due to physical and chemical processes (absorption, chemisorption and catalysis), and from aerosol impurities - by filtration through fibrous materials.

Respirators are divided into two types: the first is respirators in which a half mask and a filter element simultaneously serve as a face piece; the second cleans the inhaled air in filter cartridges attached to the half mask.

Respirators are divided into the following types: anti-dust- to protect the respiratory system from dust, smoke, fog containing toxic, bacterial and other hazardous elements, by passing the inhaled air through a filter made of special material. For filters in such respirators, materials of the FP type are used, which have high elasticity, mechanical strength, high dust holding capacity, resistance to aggressive chemical substances and excellent filtering properties. Dust respirators do not protect the respiratory system from gases, vapors and flammable substances.

gas mask- for protection against vapors and gases by filtering the inhaled air through filter cartridges of various brands, differing in the composition of the adsorbent material. At the same time, the filter cartridge of each brand protects against gases of a certain type only;

universal- simultaneously protect from aerosols and certain types of gases and vapors. Respirators have an aerosol filter and replaceable gas cartridges of different brands.

According to their design, respirators of two types are distinguished: filtering masks - their filtering element simultaneously serves as a front part; cartridge - independently made front part and filter element.

By the nature of the ventilation of the mask space, respirators are divided into valveless (inhaled and exhaled air passes through the filter element) and valve ones (inhaled and exhaled air moves through different channels thanks to the system of inhalation and exhalation valves).

Depending on the service life, a distinction is made between disposable and reusable respirators, which provide for the possibility of replacing filters or their repeated regeneration.

Fine-fiber filtered materials are used as filters in anti-dust respirators.

Depending on the service life, respirators may be disposable, which after processing are not suitable for further use. Reusable respirators are designed for filter replacement.

Respirators have a number of advantages: low breathing resistance, low weight. This prolongs the time in the respirator and reduces pressure on the face. However, their use is prohibited to protect against highly toxic substances such as hydrocyanic acid, etc., as well as against substances that can enter the body through intact skin.

To protect against harmful vapors and gases (when performing disinfection work, dressing seeds), a gas mask is used . It is attached to a rubber half mask with two replaceable gas cartridges with activated carbon and other absorbers. The respirator can be equipped with cartridges of different brands (A, B, KD, G), differing in the composition of the absorbers: A - from vapors of organic substances (gasoline, acetone, ethers, benzene, formalin, alcohols); B - from hydrogen sulfide, sulfur dioxide, vapors of organochlorine and organophosphorus pesticides; KD - from ammonia, hydrogen sulfide and their mixture; Г - from vapors of mercury and its compounds. Cartridges are marked on their body. Respirators are used when the oxygen content in the air is more than 17% and the total concentration of harmful gaseous substances is less than 15 MPC.

Industrial filtering gas masks are used to protect the respiratory organs, eyes and skin of the face when the oxygen content in the air of the working area is not less than 18% and the concentration of harmful substances at the level of 50 ... 2000 MPC. The set of an industrial filtering gas mask includes a rubber face (helmet-mask) with a corrugated tube, a filter box of a cylindrical truss with a sorbent (absorber), and a bag for carrying a gas mask. The inhaled air passes through the filter box, and the exhaled air is removed through the exhalation valve, which ensures that the inhaled air is purified from harmful impurities.

It is forbidden to use filtering gas masks when the air is contaminated with harmful substances of unknown composition and concentration, when carrying out any work inside containers, in wells, collectors and other similar equipment. Filtering RPEs are not used in the presence of non-absorbable substances such as methane, ethane, ethylene, acetylene.

Depending on the content of harmful substances in the air, its temperature, humidity, speed of movement, the protective action time of an industrial filter gas mask is different and ranges from 30 to 360 minutes. The approximate periods of protective action of gas masks are given in the instructions attached to them.

Isolating RPE (breathing apparatus) are used with a lack of oxygen (less than 18%) in the air and an unlimited concentration of substances harmful to humans.

For insulating RPE, there are practically no restrictions in use, because they completely isolate the respiratory system from the environment, and air enters the mask space through a hose from an uncontaminated area or from an individual supply in cylinders.

Industrial gas masks are designed to protect the respiratory system, face and eyes from harmful substances present in the air in the form of gases and vapors.

According to the principle of supplying clean air under the mask, gas masks are divided into two groups: filtering and insulating.

In filtering gas masks, the air taken from the working area is preliminarily cleaned of harmful vapors, gases and aerosols (when passing through the filter element). To ensure respiratory protection, the filter box with sorbent must be suitable for the gases and vapors in the air.

The gas mask consists of a helmet-mask with inhalation and exhalation valves and a gas mask box, interconnected by a corrugated tube. The small filter box is attached to a helmet-mask without a corrugated tube.

Types of gas masks

a) hose; b) autonomous

Gas masks are equipped with boxes of two sizes (large and small) and three types: without an aerosol filter, with an aerosol filter (there is a white vertical stripe on the box) and without an aerosol filter with a reduced breathing resistance (has an index of 8 in the marking). Depending on the type of harmful substance, boxes of the following brands are produced: A, B, G, E, KD, CO, C, M (table 1).

Isolating gas masks for the air supply system under the helmet-mask are produced in two varieties: hose and autonomous.

Gas masks are used with a total volumetric dose of harmful gaseous substances in the air of no more than 0.5%. Filtering masks cannot be used in the presence of non-absorbable substances (methane, butane, acetylene, ethane and other gases) in the air, when the oxygen content in the air is less than 17%, as well as in cases where the type of harmful gas is unknown.

The principle of operation of a hose gas mask is based on the fact that the worker, being in a gas-hazardous space, receives clean air under the mask from an area where no harmful substances are contained.

In self-contained gas masks (oxygen-isolating), oxygen or a mixture of it with other gases from a knapsack oxygen cylinder with a reducer is supplied to the respiratory organs. The operating time in such a gas mask is limited by the capacity of the cylinder.

Insulating gas masks are used when working in wells, tanks, in case of fires and in other cases when it is impossible to use respirators and filtering gas masks.

Insulating substances.

Insulating gas masks, unlike filter masks, completely isolate the respiratory system from the environment. Breathing is carried out due to the supply of oxygen in the gas mask itself. An insulating gas mask is used when it is impossible to use a filtering one, in particular when there is a lack of oxygen in the environment, at very high concentrations of OM, SDYAV and other harmful substances, when working under water.

The principle of operation is based on the release of oxygen from chemicals, while absorbing carbon dioxide and moisture exhaled by a person.

Isolating gas masks consist of a face piece, a regenerative cartridge, a breathing hose and a bag.

The regenerative cartridge provides oxygen for breathing, absorption of carbon dioxide and moisture from the exhaled air. The body of the cartridge is equipped with a regenerative product, in which a starting briquette is installed, which provides the release of oxygen, which is necessary in the first minutes for breathing.

The supply of oxygen in the regenerative cartridge allows you to perform work under heavy physical exertion for 45 minutes, with average -70 minutes, and with light or at a state of relative rest -3 hours.

Resistance to breathing in the aisles of the norm. An increase in resistance occurs only in faulty gas masks or if the overpressure valve is defective.

The simplest respiratory protection.

When there is neither a gas mask nor a respirator, that is, those protective equipment that are manufactured by the industry, you can use the simplest: a cotton-gauze bandage or an anti-dust cloth mask. They rather reliably protect the human respiratory system from radioactive dust, harmful aerosols and bacteriological agents. A cotton-gauze bandage soaked in a certain solution will provide protection against SDYAV such as highor and ammonia. However, neither a cotton-gauze bandage, nor PRM protects against many poisonous potent substances.

A cotton-gauze bandage is made of gauze 100 cm long and 50 cm wide. An even layer of cotton wool 30 * 20 cm in size and 2 cm thick is placed on the middle part of the gauze.When using, a cotton-gauze bandage is applied to the face so that the lower edge covers the bottom of the chin , and the upper one reaches the eye sockets, well covering the mouth and nose. The cut ends of the bandage are tied like this: the upper ones are at the back of the head, the lower ones are at the crown.

The PTM mask consists of two main body parts and mountings. The body is made from 4-5 layers of fabric. The upper one is made of loose fabric, the inner layers are made of denser fabrics, and the lower inner layer is made of non-fading fabric, since it is adjacent to the person's face. The cutting of the case is carried out according to patterns or patterns. It is not recommended to use cotton-gauze bandages for a long time. It is necessary to leave the contaminated area as soon as possible.

Construction of RPE

To prevent contaminated air from entering the respiratory system, the RPE must separate them from the surrounding polluted atmosphere (for this, front part), and provide the employee with clean or purified air suitable for breathing (filters are used for this, or a source of clean air: external - with supply through a hose, or autonomous - supply in cylinders, in a chemically bound form, etc.). The type of RPE and its protective properties depend on the design of its components and the principle of operation (see Respiratory Personal Protective Equipment Classification) .

Front part

The face part of the RPE is the part of the RPE that connects the user's respiratory tract to other parts of the device and separates the respiratory tract from the surrounding atmosphere. The face part can be either tight-fitting (for example, mask, half-mask, quarter-mask) or loose (for example, helmet, hood).

Facials that fit tightly to the face

Mouthpiece- the front part of the RPE, held by teeth or teeth and a headband, tightly compressed by the lips and through which air is inhaled and exhaled, while closing the nose with a clip. For a more secure fit, it can be equipped with a chin rest. It is mainly used in self-rescuers.

Quarter mask covers the mouth and nose, but does not cover the chin. In the USSR, quarter-masks were not made, and in the Russian Federation they did not receive distribution.

Half mask covers the mouth, nose and chin. Can be made of filter material (filter half mask) or airtight elastomer material (elastomer half mask). Elastomeric half masks are made with removable gas mask, anti-aerosol or combined filters, or they are connected to a source of clean air. Elastomeric half masks with non-removable filters (disposable) are also produced, but they have not become widespread in the Russian Federation.

Full face mask covers the mouth, nose, chin and eyes, is used with replaceable filters, or connected to a source of clean air.

- Due to the tight fit, these face pieces can be used in inexpensive RPEs that do not have a forced supply of breathable air under the mask, since they are able to prevent ambient air from entering the respiratory system during inhalation. And when these face pieces are used in conjunction with a pressurized source of breathable air under the mask, their protective properties are greatly enhanced.

Facials with a loose fit to the face

Air Hood- The face part of the RPE, which is freely worn on the head, which completely covers the head, is usually made of impermeable fabric.

Pneumatic helmet- the front part (hard), which covers the face and head, and additionally provides protection of the head from mechanical stress.

Pneumatic jacket- the front part, consisting of a hood and jacket, made of impervious materials.

Pneumosuit- the front part, made of impermeable material, and completely covering the whole body. Air jackets and air suits provide the most reliable protection for employees, and are used mainly in the nuclear industry (when clean air is supplied through a hose).

Breathable air source All of these face pieces can only be used when they are forcedly supplied with air (pressurized, continuously, or on demand while inhaling). For air supply, autonomous sources (filter purification units, cylinders, etc.) can be used, or remote ones - with supply through a hose.

In filtering RPEs, contaminated ambient air is used after it is cleaned by filters to provide the employee with breathable air. Air can be pumped through the filters either due to a vacuum under the face (when inhaling), or forcibly - using a fan. In the latter case, the air flow through the filters is greater, which reduces their service life, but the vacuum under the mask during inhalation is either less or absent, which reduces the leakage of unfiltered air through the gaps between the mask and the face, and significantly increases the protective properties of the RPE. Such RPE cannot be used with insufficient oxygen content in the air.

In isolating RPE, to provide the employee with breathable air, an autonomous (portable) source can be used (see Self-contained breathing apparatus), or clean air can be supplied through a hose - in a hose-type RPE. In the latter case, in case of interruptions in the air supply, the employee may find himself in a polluted atmosphere without protection, therefore, in developed countries, they require the use of hose-type RPE together with a supply of air (for example, in a small portable cylinder) sufficient for safely leaving the contaminated workplace. Such RPE can be used in case of insufficient oxygen content in the ambient air (in wells, in case of fire, etc.).

Selection and application of RPE in industry

Choice of RPE

At RPEs with different facepieces and in different ways air supply (self-priming during inhalation, forced supply - on demand under pressure, continuous and on demand) different protective properties. Therefore, for reliable protection of the health of employees, it is necessary to use a RPE that provides the degree of respirator protection that is necessary for the measured air pollution of the working area. If the air pollution is not precisely known, then the legislation of developed countries allows the use of only the most reliable RPE, for example, self-contained breathing apparatus.

Application of RPE in industry

With the correct choice of RPE, its effectiveness in practical use depends very much on how correctly the front part is matched to the face of a particular worker (if there is a discrepancy in shape and size between the mask and the face, gaps arise through which polluted air can enter the respiratory organs), and on how correctly the RPE is used. Therefore, in developed countries, where both the employer and the PPE manufacturer are liable in the event of injury to the worker, the use of PPE takes place within the framework of a (written) respiratory protection program, is regulated in detail by legislation and - in accordance with the requirements of this legislation - is checked by inspectors (planned, and on employee complaints). To regulate the choice and organization of the use of RPE in developed countries, respiratory protection standards have been used for several decades (see. Legislative regulation selection and organization of respirators, and to verify compliance, specific inspection instructions for inspectors).

The relationship between health preservation, the quality of RPE and the organization of their use

In developed countries, there are also standards for the certification of the RPEs themselves - as separate devices. These standards are intended to additions respiratory protection standards by ensuring a certain minimum level of product quality. For example:

The standard for the certification of half-mask respirators contains certain requirements for its quality, the fulfillment of which allows, with the right choice and correct application, to reliably ensure a 10-fold reduction in the contamination of the inhaled air (USA). On the other hand, the standard for the selection and use of respirators requires that the selection of a half mask should not be used when the air pollution exceeds 10 MPC, that only certified half masks are purchased, and that the employer takes a number of specific measures to ensure the correct individual selection and correct use of half masks by trained workers.

The combination of meeting the requirements for the quality of RPE and meeting the requirements for their correct selection and organization of the correct use allows to ensure sufficiently reliable health protection, and to avoid the occurrence of occupational diseases and the death of workers. This was confirmed by numerous measurements of the protective properties of various types of RPEs, which were carried out directly during work in various industrial conditions (see Tests of respirators in industrial conditions), as well as when simulating the performance of work (in the laboratory) and calculations made on the basis of statistical processing of measurement results .- The standards for the certification of gas mask filters contain specific requirements for the protective properties of different types of filters when exposed to several specific harmful gases - under strictly defined conditions. However, the conditions for using these same filters may differ from laboratory (for certification), and the filter life can also be very different from that required for successful certification. In addition, the amount of harmful substances for protection against which gas filters are used is hundreds of times greater than the amount of gases used for certification, and the service life of a gas filter can greatly depend on the type of harmful gases, or their combination. Therefore, in order to timely replace the gas mask filters, the legislation obliges the employer to use filters with end-of-life indicators, or to replace filters on a schedule, using the results of life calculations made using special computer programs or other methods.

Requirements for choosing PPE

In addition to the established rules, an important aspect in the choice of protective equipment is the certificate.

In accordance with the physical state of harmful components, RPE are divided into the following classes:

- gas mask;

- anti-aerosol;

- combined (gas and aerosol).

Filtering RPEs are characterized by the following indicators:

- the maximum concentration of harmful substances at which the use of a protective agent is allowed;

- permeability coefficient and suction rate;

- coefficients of protective action.

However, the Technical Regulations of the Customs Union lacks information to determine the area of permissible use of funds for different designs. Therefore, workers often receive inappropriate or ineffective respirators.

Nomenclature and purpose of gas mask boxes

Coloring the box

Harmful substances (separately and their mixtures), from which protection is carried out

Brown

Vapors of organic substances (gasoline, kerosene, benzene, acetone, carbon disulfide, alcohols, ethers, tetraethyl lead, etc.)

Brown with white stripe

Acid gases and vapors (sulfur dioxide, chlorine, hydrogen sulfide, hydrocyanic acid, nitrogen oxides, hydrogen chloride, phosgene)

Yellow with white stripe

The same, as well as dust, smoke, fog

Arsine, phosphine, as well as acid gases and vapors of organic substances, but with a shorter protection period than grades A and B

Black with white stripe

The same, as well as dust, smoke, fog

Bicolor: yellow and black

Vapors of mercury, as well as chlorine and organic substances, but with a shorter protective time than grades A and B

The same, with a white stripe

The same, as well as dust, smoke, fog

Ammonia and hydrogen sulfide, as well as vapors of organic substances, but with a shorter protective time than grade A

Gray with white stripe

The same, as well as dust, smoke, fog

Carbon monoxide (CO)

Carbon monoxide and accompanying small amounts of organic vapors, acid gases, ammonia, arsine, phosphine

Protective green with white stripe

Acid gases and organic vapors (with a shorter protection time than boxes of grades A and B, arsine, phosphine, hydrocyanic acid in the presence of dust, smoke, fog)

Respirators and gas masks are designed for individual use and after fitting to the worker's face should be at his personal disposal.

The face part of respirators and gas masks is sized in such a way as to ensure a tight fit to the face and eliminate pain during work.

To check the tightness of the face part of the respirator, close the exhalation valve holder with your palm and breathe out lightly. If at the same time the air does not come out of the half mask, then the respirator is selected in size and fitted to the face correctly. If not, the fit must be repeated with a smaller respirator.

The face parts of the gas masks have five sizes: 0, 1,2, 3, 4. The size of the gas masks is selected according to the sum of two measurements of the head in centimeters: 1) the length of the circular line passing along the chin, cheeks and through the highest point of the head; 2) the length of a semicircle passing along the forehead through the brow ridges from the opening of one ear to the opening of the other (see Figure 8). The measurement results are added and the required size of the gas mask helmet is determined from the following ratios:

Sizes of gas masks

To determine the correct selection of the helmet-mask and its serviceability, it is necessary to put on a gas mask, close the inlet of the gas mask box or corrugated tube with your palm and try to inhale deeply. If breathing is impossible, then the mask is selected correctly and the gas mask is sealed. When passing air, check the tightness of all elements and connections of the gas mask and the correctness of its fit.

When choosing a RPE, it is necessary to take into account chemical composition, and the quantitative content of harmful substances in the working area, toxicity and dispersed composition of dust, working conditions, its severity and duration, as well as meteorological conditions and oxygen content in the air.

Determining the size of the gas mask

Rules for the use of protective equipment

To protect the worker from inhaling contaminated air, filtering protective equipment must be used in a timely manner to separate the respiratory organs from surrounding contaminants, providing the technician with filtered air that complies with regulations.

Due to the fact that sometimes it is not possible to determine the excess of the concentration of polluting components over the MPC, it is difficult to use respirators in a timely manner. Therefore, industrial hygienists consider the use of PPE as the most unreliable method, and legal requirements in developed countries are aimed at improving the working conditions of the employer. Wherein secondary role plays providing employees with effective RPE.

Even with the timely use of respirators, harmful substances can enter the body through the respiratory organs. They can seep through gaps between the face and mask, penetrate the skin or an ineffective filter. Gaps may appear if the mask is not carefully put on, if it does not match its size, shape, or if it slips during operation. In accordance with numerous studies of the protection of respirators, differing in models and designs, which were carried out in different industrial conditions, it was shown that the overall effectiveness of protective equipment is determined by the flow of air into the gaps.

To make the working air suitable, you should choose the right filters and replace them in a timely manner. Problems with changing filters, preventing the penetration of untreated air into the gaps between the face and the mask when it slips, influenced the emergence of an indicator for assessing the possibility of using a RPE. This criterion determines concentrations that are dangerous to human health and life.

It is considered that a hazardous concentration is one that, upon short-term exposure, may impair the health or death of an employee. When working in hazardous conditions, an insulating RPE should be used, where a constant overpressure is created under the mask.

Detailed and right choice protective equipment for the respiratory system contributes to an increase in the level of organization of the use of RPE, a decrease in the incidence of occupational diseases.

Ask a Question

Show all reviews 0Read also

The use of personal respiratory protection is the last option to protect the worker from inhaling airborne contaminants. Unfortunately, this last remedy is also the most unreliable - in relation to the use of technological and technical methods, and means collective protection ventilation. Therefore, in order to minimize the risk of damage to health when using respirators, the quality requirements for the RPE have been developed; the manufacturer fulfills them during certification.

After the first-ever gas attack by a cloud of chlorine in 1915, filtering devices were created to protect against chemical weapons masks in which the inhaled air is passed through activated carbon. Further development of funds mass destruction and potentially hazardous industries using highly toxic substances has led to the need to create new and new portable personal protective equipment that allows a person to survive and operate in a deadly environment.

1. How to choose the right size for a gas mask. The effectiveness of the protection of a gas mask depends on the correct determination of its size. To determine which size is needed, you need to measure the head according to the following instructions and using a measuring tape we measure the circumference passing through the crown, chin and cheeks b using a measuring tape we measure the circumference passing through the holes of the ears and eyebrows in adding both indicators

Gas mask device There are several types of combined-arms filtering gas masks RSh, PMG, PMK, etc. Varieties of combined-arms gas masks Below are the elements of gas masks and their brief characteristics. The face part of a helmet-mask or mask is designed to protect the face and eyes, supply purified air to the respiratory organs and discharge exhaled air into the atmosphere. It consists of a body, a spectacle valve box assembly,

Respiratory protection equipment (RPE), a technical device worn on a person that protects the respiratory system from occupational risk factors GOST R 12.4.233-2012, p. 2.99. The general name for respirators and gas masks used when working in a polluted atmosphere or in an oxygen-deficient atmosphere. Air jackets and air suits used in the nuclear industry can also be referred to the RPE. RPEs are the latest, and at the same time the most unreliable

The purpose of using personal protective equipment for respiratory organs is to provide the necessary respiratory protection for workers in an environment hazardous to their health. If there is a risk of negative effects of substances harmful or hazardous to the health of workers, the employer is obliged to analyze the state of the working environment, including measurements of the concentrations and composition of substances in the air of the working area. Without this, it is almost impossible to correctly implement the protection of workers, choose

All products by tags

Related Products

To protect the respiratory system from harmful vapors and gases present in the air of working areas of industrial premises in a concentration not exceeding the MPC by more than 10 times. It is a universal breathing apparatus of the filtering type, has a knitted seal and a rubber half mask with a device for installing replaceable cartridges. Designed to protect: grade "B" - from acid gases and vapors (sulfur dioxide, chlorine, hydrogen sulfide, hydrocyanic acid, hydrogen chloride, phosgene, phosphorus and chlorine-containing pesticides); Normative technical documentation: GOST R 12.4.190-99 SSBT. Respiratory PPE. Half masks and four masks made of insulating materials. General technical conditions.

A simple panoramic mask, specially modified for use in apparatus with excess pressure in the space under the mask. The design of the mask uses a valve box with a 45x3 connecting thread that meets international standards. It is used with breathing apparatus: AP-96M, AP "Omega-S", self-rescuers ADA-Pro. Normative technical documentation: GOST R 12.4.189-99 SSBT. Respiratory PPE. Masks. General technical conditions.

Provides protection of the respiratory system, eyes and face from gases, vapors and aerosols. Distinctive characteristics: economy, long service life. High protection, low breathing resistance. Wide panoramic lens for excellent visibility and anti-fogging. Impact-resistant, scuff and scratch-resistant polycarbonate lens. Low weight. The material is non-irritating. The half mask is used with replaceable cartridges and pre-filters. Wide range of spare parts. Protection degree up to 200 MPC. Normative technical documentation: GOST R 12.4.189-99 SSBT. Respiratory PPE. Masks. General technical conditions.

To protect the respiratory system from harmful vapors and gases present in the air of working areas of industrial premises in a concentration not exceeding the MPC by more than 10 times. It is a universal breathing apparatus of the filtering type, has a knitted seal and a rubber half mask with a device for installing replaceable cartridges. It differs from the RPG-67 respirator by the presence of an aerosol filter in the cartridges. Designed to protect: grade "B" - from acid gases and vapors (sulfur dioxide, chlorine, hydrogen sulfide, hydrocyanic acid, hydrogen chloride, phosgene, phosphorus and chlorine-containing pesticides); Normative technical documentation: GOST R 12.4.190-99 SSBT. Respiratory PPE. Half masks and four masks made of insulating materials. General technical conditions.

Size: 23 × 12.5 × 10.5 cm Inner pocket size: 9 × 9 cm Material: Cordura® 500d (100% nylon) Weight: 182 g Lanyards: 100% nylon Threads: Liberty® (Netherlands) filament bonded nylon Hardware : Duraflex® * The manufacturer reserves the right to make changes to the design, materials and equipment of products without prior notice to the consumer. Recommended for carrying the JetBoil Sumo torch. An improved model that replaces the old one. Structurally, it is a complete analogue of the Small luggage pouch on fastex, but with different dimensions (already and higher) Mount: UniClick system of the third generation. Two built-in clips. For mounting on classical system PALS / MOLLE requires three cells in width and from two to four horizontal rows of cells in height. The pouch fastens with fastex fastex (fast, fast buckle, "trident") semi-automatic fastener for connecting fabric tapes, slings, belts. The name "fastex" originates from a division of the company ITW (Illinois Tool Works) ITW Fastex. ... Learn about the Fastex from the Duraflex® Encyclopedia, adjustable A small flat Velcro pocket is sewn on the inside of the top of the valve from the inside out for a set of anti-fog films for gas mask lenses. On the new model, the Velcro is sewn with a reinforced method, a grip from the sling has been added for easy opening. The outer surface is sheathed with PALS cells for attaching additional pouches. In the new model, the PALS rows are arranged more rationally - they are shifted relative to the old position and sewn in the classic way (with a gap between the rows in the width of the sling). Only three rows in height (in the old version, the pouch is two). Mesh width 37 mm instead of the old size 35 mm The pouch is sewn entirely from lighter Cordura® 500d fabric instead of the old version 1060d All fabric edges are edged for reliability and neat appearance All ends of Uniclick and PALS lines are hidden under the edging. At the bottom there is a grommet for water drainage. The place of its installation is reinforced with a sling to protect it from pulling out REVIEWS: Discussion on the forum

To protect the respiratory system from different types dust: plant, animal, metal, mineral. It is a filtering mask, the filtering layer of which is made of a material based on synthetic ultrafine fibers. The exhalation valve allows excess heat and moisture to be removed with less air resistance during exhalation. The operating time is up to 30 shifts, depending on the concentration of dust, humidity and air temperature, as well as physical activity. Normative technical documentation: GOST R 12.4.191-2011 SSBT. Respiratory PPE. Filtering half masks for protection against aerosols. General technical conditions.

Used to store and carry gas masks. Normative technical documentation: GOST 12.4.041-2011 SSBT. Filtering PPE for respiratory organs. General technical requirements.

Dust and fog protection. Fits snugly to the face. The parabolic expiratory valve effectively removes heat and moisture for easy breathing. The cup shape and crush resistance provide reliable, comfortable protection, especially at elevated temperatures and humidity. Weight: 13 g. Provides protection for FFP2 (up to 12 MPC) Normative technical documentation: GOST R 12.4.191-2011 SSBT. Respiratory PPE. Filtering half masks for protection against aerosols. General technical conditions.

Durable half-mask respirator for harsh industrial conditions. The fastening system consists of two elastic rubber straps on a cotton base and the headband is adjustable in four points. Silicone backing material, not allergic, softly and tightly adheres to the clit along the obturation line. High efficiency of heat and water vapor removal from exhaled air. Compatible with eye and head protection. Sizes S, M, L. Normative technical documentation: GOST R 12.4.190-99 SSBT. Respiratory PPE. Half masks and four masks made of insulating materials. General technical conditions.

Filters are used with a total concentration of toxic substances of no more than 0.1% by volume. Resistance of filters to a constant air flow at a volumetric flow rate of 30 dm³ / min no more than 100 Pa (102 mm of water column). Filters can be used in all climatic zones of Russia, the working temperature range is from -40 to + 50 ° С. The filter housing is made of polypropylene in the form of a cylinder. Filter weight 300g. It is forbidden to use filters to protect against carbon monoxide, low-boiling organic substances (methanes, ethane, butane, ethylene, acetylene, etc.) and if the composition of the polluted atmosphere is unknown. The guaranteed shelf life is 5 years from the date of manufacture. А2В2Е2К2Р3 - from vapors of organic substances with a boiling point above 65 ° С, inorganic gases and vapors, sulfur dioxide, arsenous and hydrogen fluoride, ammonia, hydrazine, organic amines, aerosols Normative technical documentation: GOST R 12.4.193-99 SSBT. Respiratory PPE. Gas and combined filters. General technical conditions.